Hydraulic control

With the hydraulic-specific control algorithms fully integrated in machine control and the flexible and scalable hardware architecture, it is possible to attend the requirements of any press and metal punching machinery. With B&R it is even possible to add a hydraulic axis in a CNC with a high level of precision, dynamics and synchronization.

Machine modularity

B&R offers hardware and software solutions for fast and easy development of mechatronic machines with options that can easily satisfy the requirements of the end user.

- Servo motors with an integrated drive: ACOPOSmotor

- Servo motors with a decentrally mounted IP67 drive: ACOPOSremote

- IP67 and IP20 I/O, optional safety modules: X20, X67 I/O modules

- Stepper motors: 80MP and ACOPOSmicro

- Modular machine design

B&R offers machine builders a comprehensive selection of motor types. The Generic Motion Control (GMC) concept allows the software to be developed independently of the motor type. For each mechatronic module in a machine, the OEM can select whatever solution offers the greatest amount of freedom, which in turn saves time, resources and money.

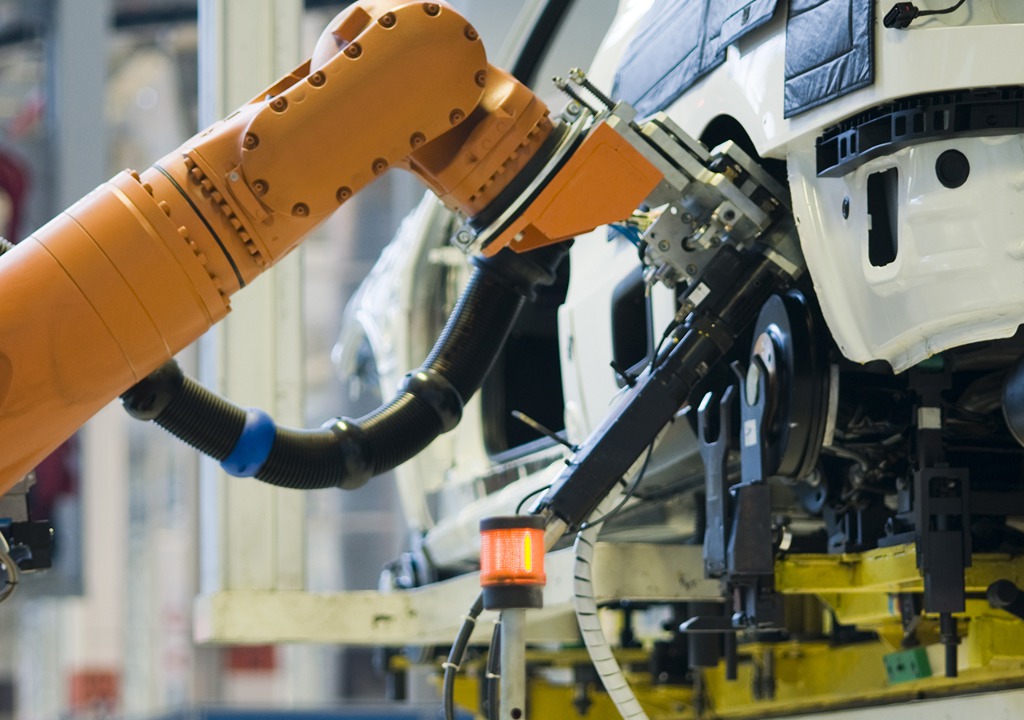

CNC & Robotics

B&R improves the efficiency of machines and systems by combining CNC, robotics and motion control into a single software platform called Generic Motion Control (GMC). One feature that makes GMC unique is that it can be used for all drive types, including hydraulic drives and servo technology. GMC integrates seamlessly into the machine application, allowing it to be customized for the specific task at hand. GMC's flexibility also permits easy integration of existing CNC and robotics dialects.

- Unified CNC, robotics and motion control

- All drive types

- Integrated safety technology

- Seamless interaction with the machine application

- Integration of existing CNC and robotics dialects

Gluing, marking and waste detection with 1 µs precision

B&R NetTime provides high-performance synchronization in real time via POWERLINK. Multiple encoder positions (real or virtual) and distributed I/O channels (analog or digital) are synchronized with 1 µs precision.

This eliminates the need for external devices for digital cam switching required by high-speed packaging machines for applications such as shooting glue, marking products and rejecting waste.

NetTime digital output patterns can be controlled with extremely short high/low times for a resolution of 125 ns. In the same way, fast input edges such as registration marks or product detection marks are recorded with a time stamp of 1 µs.

The comprehensive technology library provides a simple user interface to configure interactions between position sensors and actuators – with automatic time/position conversion and dead time compensation.

Quality assurance with an integrated vision system

B&R offers an intelligent and flexible vision portfolio consisting of cameras, lenses, lighting equipment and software. Seamless integration in the B&R control system enables synchronous data exchange throughout the entire system. The image processing functions are easy to configure and applications can be created without much programming effort.

Generic Motion Control

As processes in production lines continue to be synchronized to conveyor belts, the he division between material handling and production is disappearing. Highly complex control solutions used to be necessary to ensure the great degree of precision and speed needed for these processes. With B&R Generic Motion Control (GMC), conveyor belts and robots can now be easily synchronized with a high degree of precision.

Freedom with PLCopen

B&R provides easily configurable PLCopen function blocks that are tailor-made for these tasks. They can be used for all types of robot kinematics and even allow robots to be synchronized with multiple conveyor belts. The interfaces are also ideally suited for integrating machine visualization systems. The robot can move freely during the synchronization phase, which also enables complex product manipulation. A special feature of GMC is that the conveyor belt is fully integrated in the application. An external sensor that supplies information about the current position of the conveyor belt is all that is needed.

Hardware-independent

GMC is hardware-independent, which allows the use of different drive systems with different kinematics to be used. The application can be created quickly and easily upgraded at a later time. The robot can be replaced or the conveyor belts can be upgraded at any time without a significant amount of application engineering work. A large portion of the software can be used as-is.

- Hardware-independent

- Simple programming

- Unlimited number of conveyor belts

- Unlimited expansion possibilities

- Can be used for all kinematics

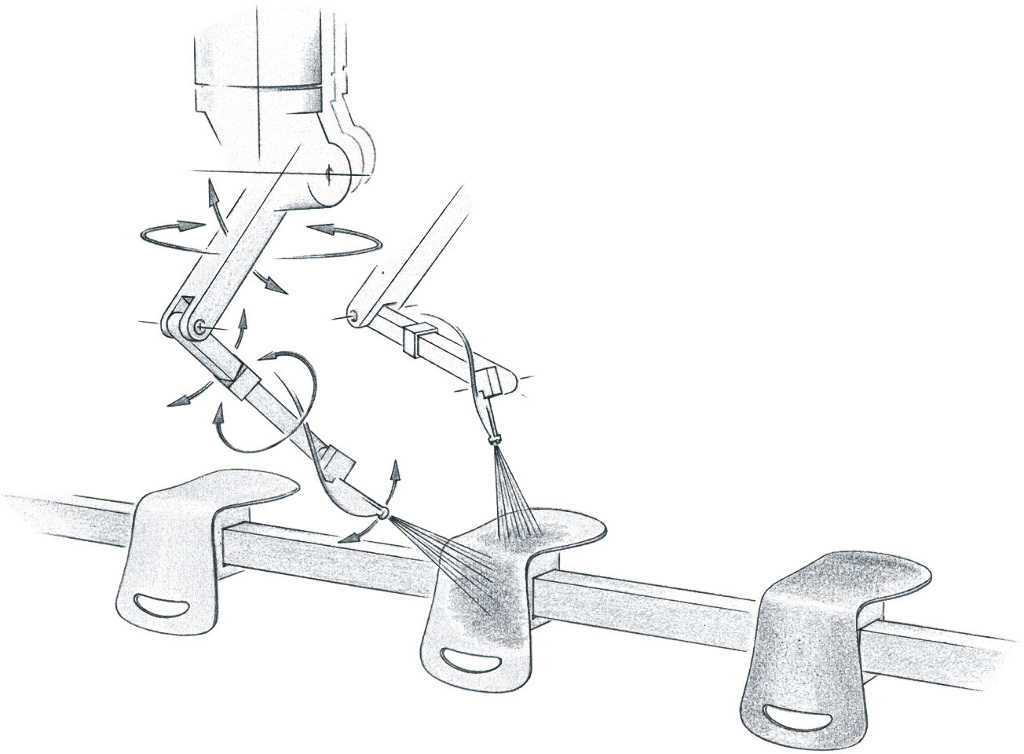

Coating robots

Controlling coating machines requires a great deal of computing power. What's more, this task is constantly becoming even more complex as more advanced coating types gain traction. With B&R's complete automation approach, coating machines and robots can be synchronized and very precisely controlled, enabling even the most demanding coating tasks to be handled efficiently. The robot does not require its own controller for this type of operation.

Humans and robots working side-by-side

In order to coat complex objects, it is necessary to teach the robot the individual movements step-by-step using teach-in methods. To achieve this, humans and robots need to work together. With SafeROBOTICS, B&R ensures that this cooperation is completely safe for humans. PC-based control technology provides the necessary computing power.

- Mobile Panel operation

- Freely definable programming language for the robot

- Safe maximum speed for all kinematic components (SafeROBOTICS)

- Standard or customized kinematic chains

B&R has the perfect solution for...

100% integration of motion, CNC and robotics

With Generic Motion Control (GMC), B&R makes possible the complete integration of CNC, motion and robotics in a homogeneous environment. GMC allows complicated tasks to be solved elegantly and efficiently, making it easy to perfectly synchronize a conveyor belt and robot, for example. The CNC or robot program generates the path for virtual axes, which can then be coupled to other (virtual) axes or actual positions (e.g. from an encoder on the conveyor belt) and ultimately transferred to real axes. Productivity increases while the workload is reduced.

Safety first!

With the openSAFETY protocol as its foundation, B&R offers the most comprehensive integrated safety portfolio on the market. The fastest response time on the market, combined with SafeMOTION function blocks such as Safe Torque Off (STO), Safely Limited Speed (SLS), Safely Limited Position (SLP) and Safe Direction (SDI), makes possible the development of previously unimaginable machine concepts. The same applies to robotics applications. Here, SafeROBOTICS monitors the entire kinematic chain. Transferring openSAFETY data via POWERLINK allows the implementation of safety solutions up to SIL 3 (IEC EN 6206) or PL e category 4 (EN ISO 13849-1). The safety controller and remote safe I/O replace conventional hardwiring and increase flexibility during commissioning and operation.

CNC or manual path generation

Painting is a complex process. Depending on the paint or coating, it may be necessary to follow different CNC paths for the same object. For this reason, it is usually preferable to enter the path manually instead of using ISO CNC programming. In addition to conventional ISO CNC or robot languages, the Generic Motion Control (GMC) concept from B&R also offers the possibility of generating a path for any type of kinematic system using points entered manually.

Powerful image processing with the Automation PC 910

Equipped with the best technology on the market, including the latest generation of Intel® Core™ i-series processors, the Automation PC 910 is the perfect choice for your most ambitious applications. USB 3.0 ports provide a perfect connection for integrating vision systems. Its modular design allows the Automation PC 910 to be customized perfectly to the demands of any application.

Advanced system diagnostics via the Web

With the latest version of the System Diagnostics Manager (SDM), B&R has added a range of powerful new diagnostic functions to an already impressive portfolio. The user profits not just from being able to access information about system hardware and software from anywhere in the world, but also from ready-made diagnostic applets that can be easily integrated directly into applications.

Since all service functions necessary for a machine or system are already integrated in the System Diagnostics Manager, it can be launched from any PC without any installation whatsoever. The only requirement is a conventional Web browser. The appearance of the System Diagnostics Manager can also be individually customized to match the look and feel of the machine or systems manufacturer using it.

Many different diagnostic options

In addition to being able to quickly access current drive values – for example, speed, position, enable status or the status of onboard inputs – the axis error list also provides information in table form about errors that are still pending as well as those that have already been acknowledged. SDM can also be used to easily access and operate drive-integrated oscilloscopes. Being able to check the current status of I/O channels on every bit of hardware with an integrated I/O viewer means that machine and system commissioning is easier than ever. The time-consuming process of testing I/O points using electrical wiring is now a thing of the past.

System dump makes support even easier

During servicing, all data in the System Diagnostics Manager can be loaded from the controller and saved to a file with a simple click of the mouse. This makes it possible for difficult service cases to be analyzed offline by a 2nd level support team. For machine manufacturers, this opens up totally new dimensions for handling maintenance and service claims.

Condition monitoring

The ability to predict machine and system failures before they happen reduces costs and increases availability. Condition monitoring modules from B&R precisely detect cases when service work may be needed and are also extremely easy to configure. All of these modules are part of the X20 control system series and can therefore be used in any control topology with no limitations. A special feature of these modules is that they perform vibration analysis locally, right on the module. The availability of fully processed results reduces the time and cost of integration to a minimum. These results also provide detailed insight into the system mechanics, allowing existing processes to be optimized with maximum efficiency.

- Preventative maintenance

- Simple configuration

- Part of the X20 control system

- Analysis locally on the module

- Optimization of processes

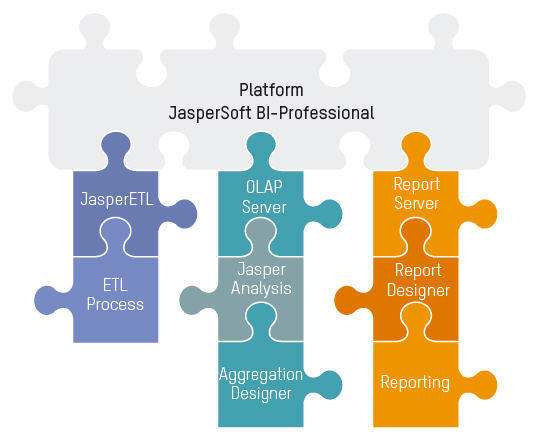

Business Intelligence

Simple evaluation of large amounts of data

B&R has upgraded the highly advanced and flexible APROL automation platform by adding a powerful system component for business intelligence (BI).

Business intelligence enables systematic analysis of recorded operating and process data. Users can gain valuable information for the decision-making process with the help of standard reports, personalized interactive reports and ad hoc reports. Native iPhone and Android apps are available for mobile access.

Market interest for BI solutions is growing steadily due to the ineffective reporting and analysis functionality provided by conventional ERP and MES solutions that is a strong driving force for change. In addition, the front end is often only useful for specialist users with IT training.

- Clear analysis

- Extremely customizable

- Easy to operate

The individual processes

| Business intelligence consists of three steps: collection, analysis and presentation. The first step involves the collection of the data. This raw data can come from an ERP system, database or file, for example. It must then be filtered, cleaned up and harmonized before it can be subjected to analysis. Simple analysis is possible with online analytical processing (OLAP) cubes. Complex statistical analysis is carried out using methods associated with data mining. In the third stage, the data is prepared for the presentation in the form of reports, PDF files or dashboards. The user can specify what data should currently be prepared. Compiling individual reports is as easy as using drag-and-drop. A manager may want boiled down, summarized performance data, while a process engineer can call up detailed information about an individual process. |

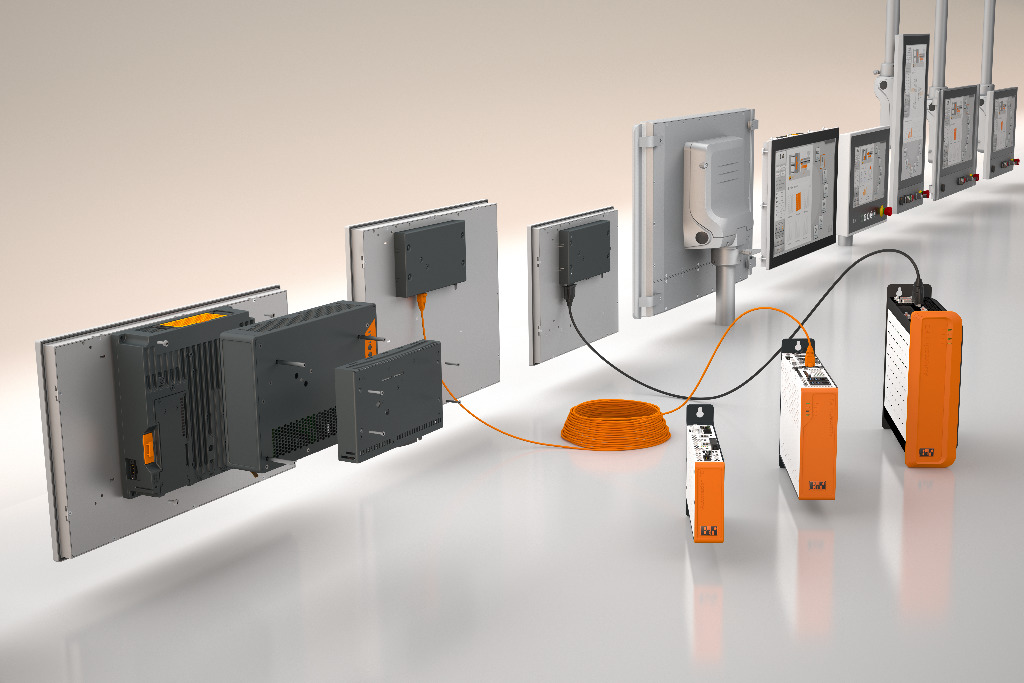

Industrial PCs

Scalable.

B&R systems adapt flexibly to any requirement.

Rugged.

Uncompromising quality for long-term operation in the harshest industrial environments.

Powerful.

The absolute highest performance classes with Intel processors: Core i3|i5|i7.

PCs from B&R are designed and built to meet industrial customers' demands for maximum robustness, reliability and long-term availability. Decision makers in a wide range of industries have selected B&R Industrial PCs, because PCs that appear cheapest at first glance are the most expensive in the long run. After all, it's the total cost over a product's life cycle that matters, and that's where the cost advantages of B&R Industrial PCs really shine.

Powerful Atom and Core™ i technology processors ensure that the most demanding automation systems run smoothly. A special form factor is available for drive system integration.

Panel PCs combine a display and a PC unit into a single extremely compact device and are available in a wide variety of display sizes with a touch or multi-touch screen and/or input keys. Designs with IP65 protection are perfect for use in especially harsh environments.

New Smart Display Link 4 transfer technology offers clear advantages for constructing modular machines and systems.

Automation Panels are the perfect HMI devices to accompany box PCs or expand panel PCs. They are available in a wide variety of display sizes with a single-touch or multi-touch screen and/or input keys.