The Open Robotics & Industry 4.0 event held in Lyon, France, demonstrated how the future of Industry 4.0 is already within reach using today’s automation technology. Following an invitation from the EPSG and its members B&R, Cognex, Comau and Festo, more than 120 industry and university experts made their way to Lyon to find out about the latest developments in the field.

100% open robot controller

The concept of integrated robotics allows synchronized operation of robots and machines. "B&R produces scalable hardware and software that makes it possible to design state-of-the-art integrated robotics solutions," explains Tomas Prchal, CNC & robotics technology manager at B&R. "Companies such as Trumpf, B+M, Leoni and Comau are already benefiting from our integrated robotics technology." Comau took the opportunity to present its latest open robotics platform, C5G Open. This open approach gives the robot control unit the added processing power of a PC with direct integration of external sensors. This simplifies the implementation of complex manufacturing applications.

Open communication standards

"The distributed automation logic that characterizes the production systems of Industry 4.0 creates an urgent need for high-speed, failsafe communication networks with unrestricted openness," explains Stéphane Potier, technology marketing manager for the EPSG in France. "With POWERLINK and openSAFETY, the foundations of the fourth industrial revolution have already been laid." Among the numerous other solutions on exhibit was the new CPX automation platform from Festo, which is particularly easy to integrate into POWERLINK networks.

Open standards are essential for the success of Industry 4.0. Along with POWERLINK and openSAFETY, OPC UA (Unified Architecture) is another key open technology. OPC UA provides complete scalability – from embedded control software to management information systems. OPC UA allows vertical communication to SCADA, MES and ERP systems as well vendor-independent communication from PLC to PLC.

Innovative safe robotics applications

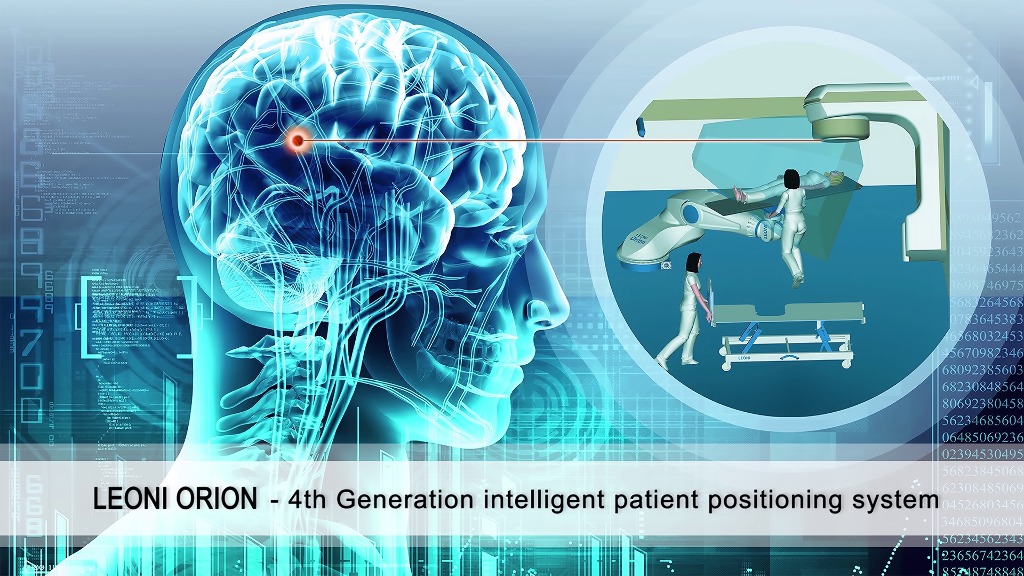

The company Leoni introduced ORION, a patient positioning system for radiotherapy treatment. Based on a 6-axis robot, this system achieves positioning precision of 0.5 mm, setting a new standard in radiotherapy robotics. Combining a safe robotics system and a sophisticated dynamic volume modeling system, the ORION robot requires high volumes of real-time data exchange between all hardware and software components. Leoni therefore decided for an open and safe robot controller based on POWERLINK and openSAFETY technologies.

Successful industry-university partnership

"The success of this Technology Day event demonstrates the benefits of our partnership with University Lyon 1," explains Jan Gadras, B&R France's technical manager in charge of university partnership. "We are happy to receive feedback from our customers that such an event, bringing together experts from industry and academia, shows the way to Industry 4.0."