The best of both worlds

May 2022

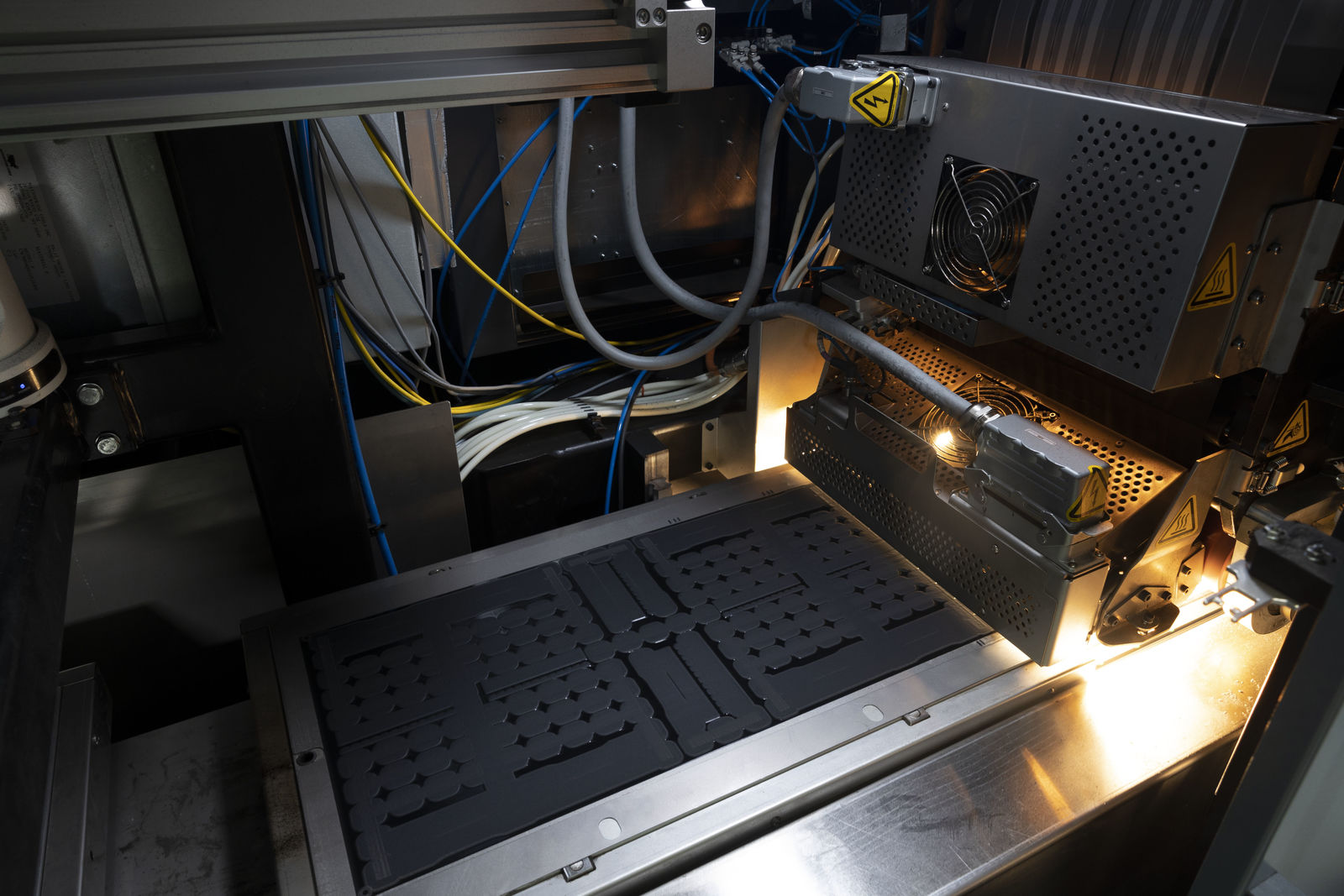

When it comes to mass producing identical parts, injection molding is king. For a rapid prototype or small run of custom pieces, nothing beats a 3D printer. Try to operate between these worlds, and you'll have to make some compromises. Or will you?

An air of confidence

April 2022

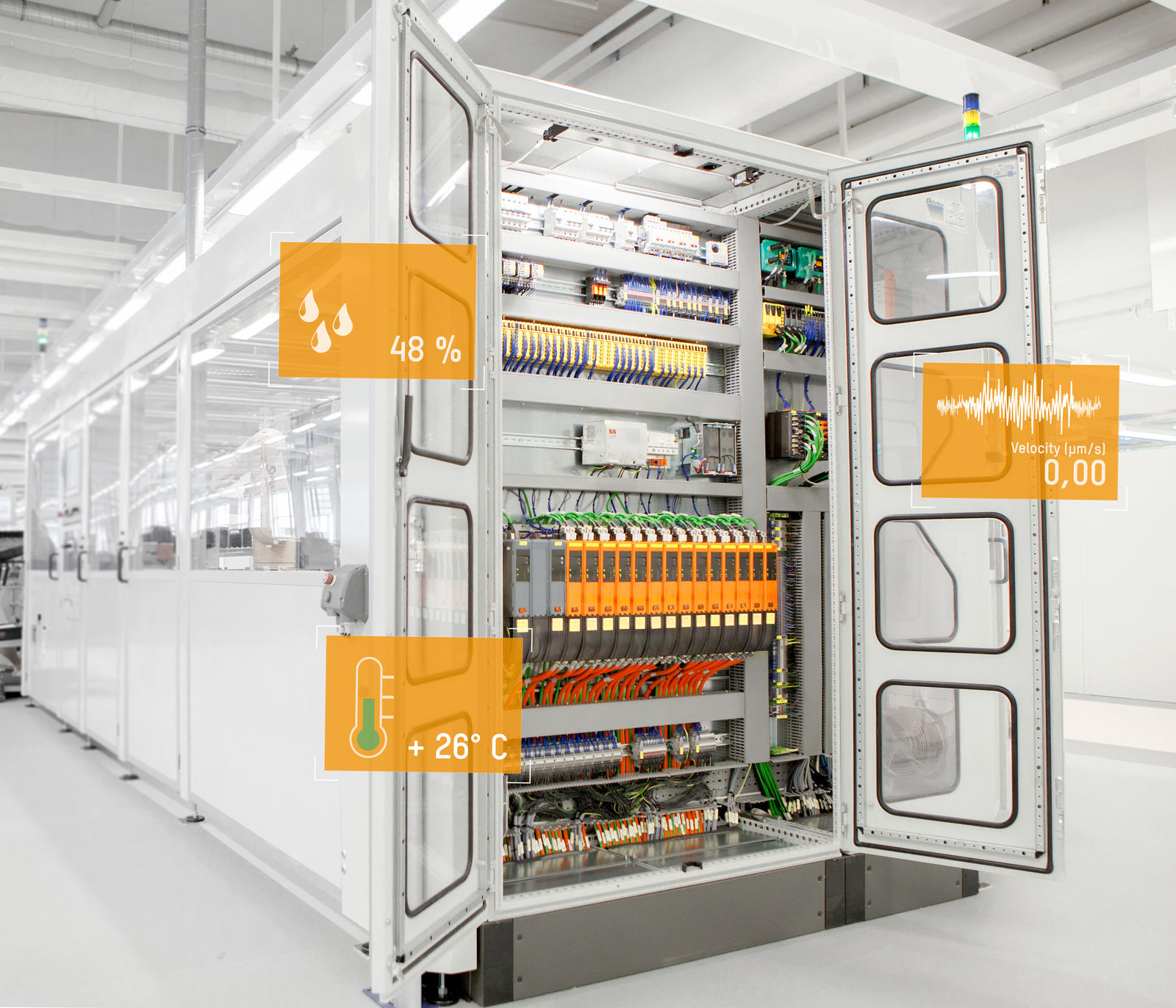

Excess heat generated in control panel enclosures must be dissipated or removed to keep electronic components functioning reliably. But how sure are you that your cooling system is doing its job? A new I/O module from B&R's X20 series puts uncertainty to rest. It monitors environmental conditions in the control cabinet without needing any additional sensors.

Retrofit for the future

April 2022

How can mixing and dosing systems become more modular, connected and easier to operate? Reinhardt-Technik has found the answer to this question in an automation solution from B&R.

IT and OT, together at last

March 2022

How do you bring IT and OT together? It's a question that must be answered by any company hoping to realize the visions of Industry 4.0. A puzzle – so far – without a real solution. But B&R is breaking down the barrier between the two worlds, giving machine builders access to one of the world's largest software ecosystems.

Eye-catching accuracy

March 2022

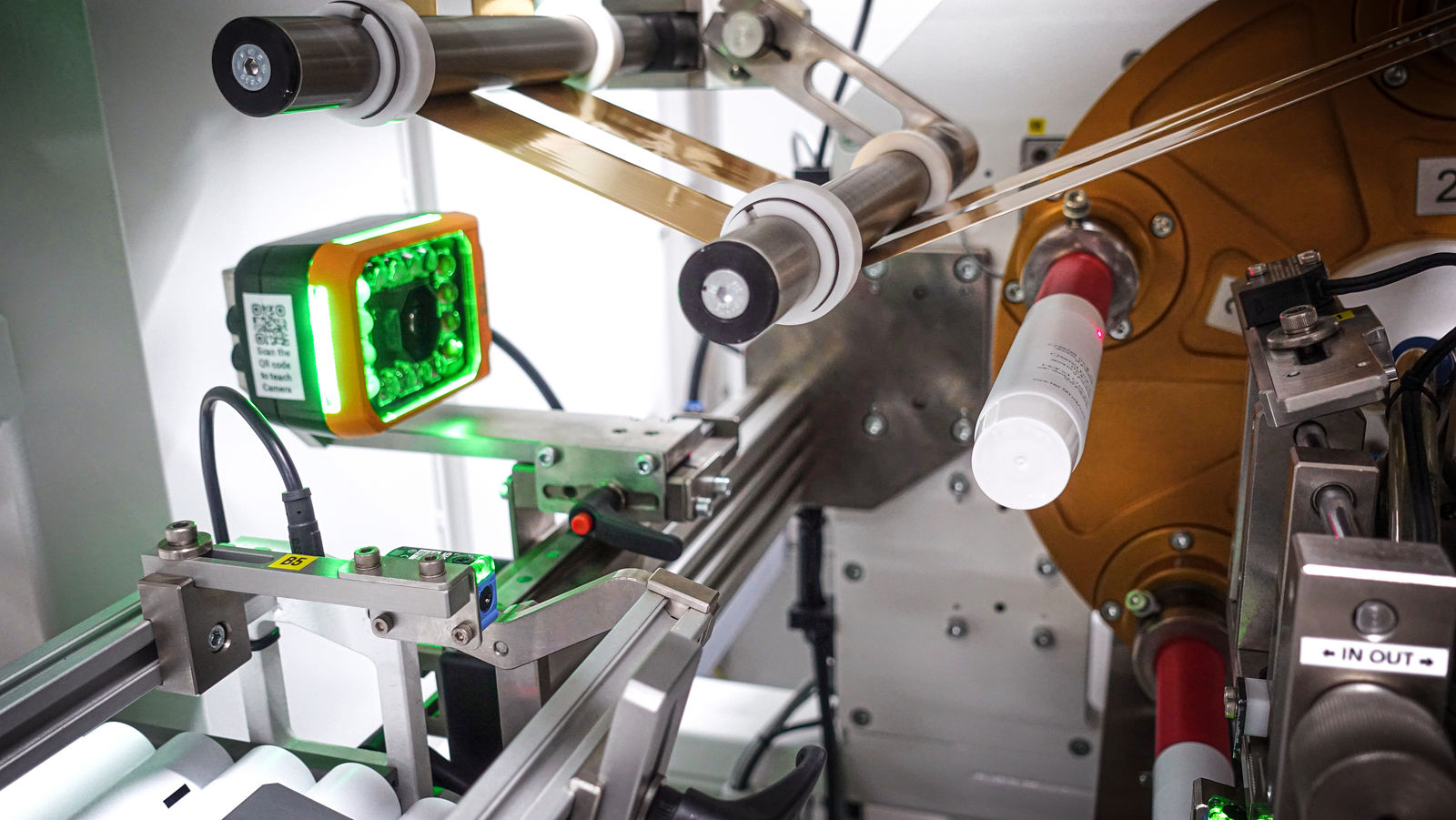

Colorful, shiny or metallic design highlights help cosmetics packaging stand out on crowded store shelves. They also help strengthen a brand's image and build customer loyalty. Known in the packaging world as high-visibility enhancements, these eye-catching elements are typically applied using a process called hot foil stamping.

"Massively reduce the footprint"

March 2022

Machine builders and plant operators have one major common goal: to make manufacturing more digital and flexible. To reach this goal, the manufacturing industry relies on research institutions such as the Graz University of Technology in Austria. At the renowned university's Smart Factory testbed, everything revolves around agile and secure manufacturing solutions. We sat down with project manager Rudolf Pichler to learn how his testbed contributes to the implementation of smart factory solutions and how manufacturing companies benefit from the knowledge that is gained there.

A winning edge

January 2022

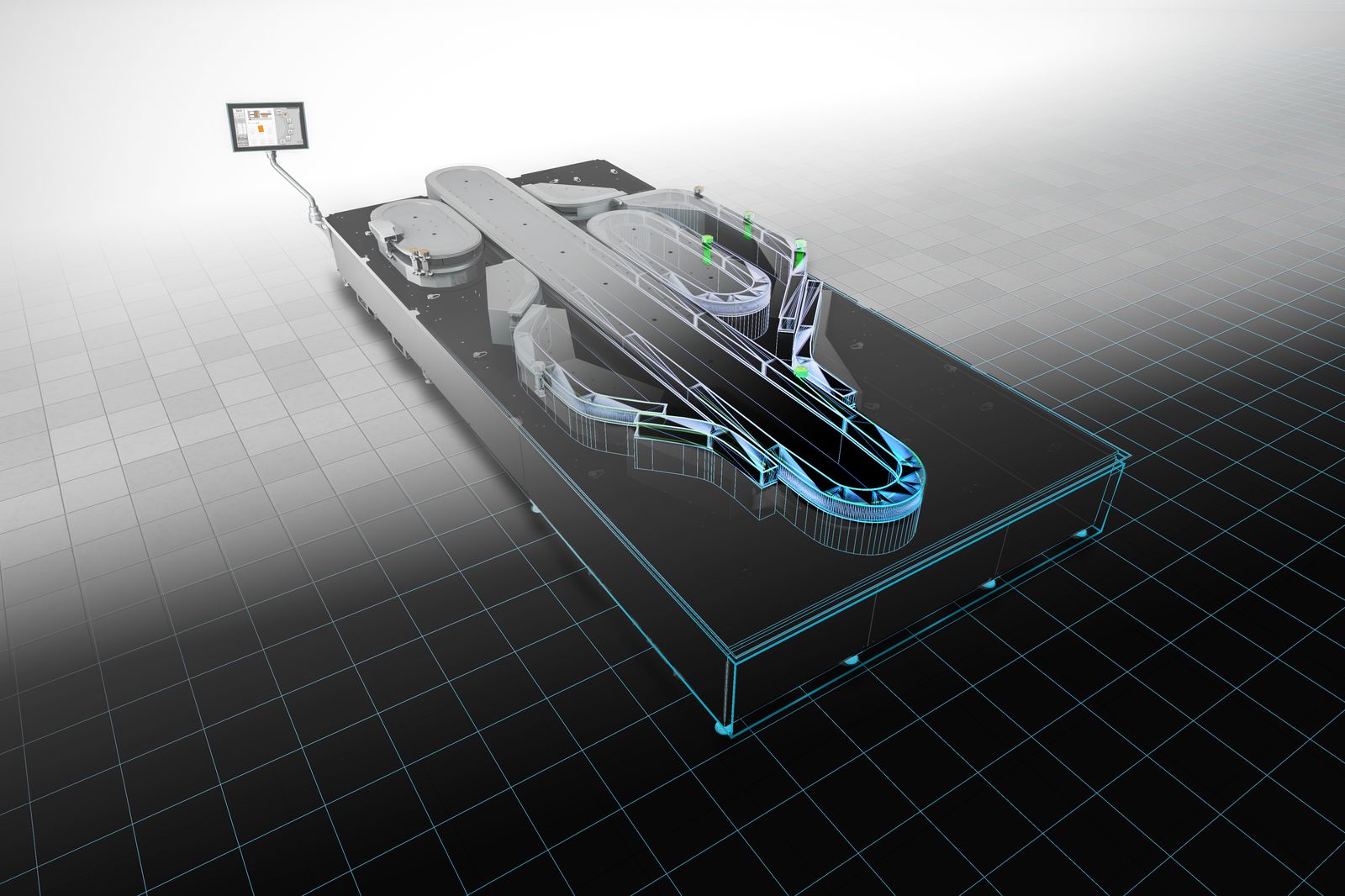

Ski type, skill level and slope conditions are just three of many factors that play an important role in the ski tuning universe. To make sure its new generation of automated ski service machines is able to handle any ski preparation task that might be required, Wintersteiger implemented a highly flexible automation solution from B&R.

Good automation runs deep

November 2021

Bauer Maschinen GmbH has automated a unique research drill rig for exploring the seabed. It was made possible by B&R automation components that function reliably, even 2,500 meters below the surface of the ocean.

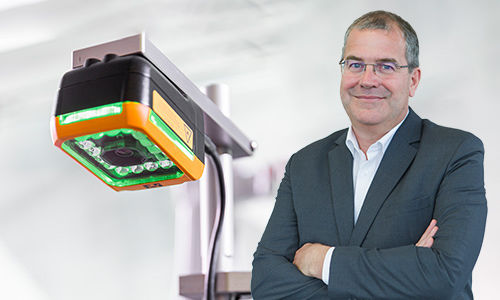

Artificial intelligence in machine vision?

November 2021

When people speak about innovative machine vision, the topic of artificial intelligence is sure to come up. Is AI the future of image processing? Our vision specialist Andreas Waldl has the answers.

"Like a battery production superhighway"

November 2021

The automotive industry is gearing up for a future dominated by electric vehicles. We sat down with B&R's electromobility expert, Ronny Guber, to learn about the important role batteries will play in that future, and what automation challenges car manufacturers and their suppliers will need to master in order to come out ahead.

"At some point, the dominoes start to fall"

November 2021

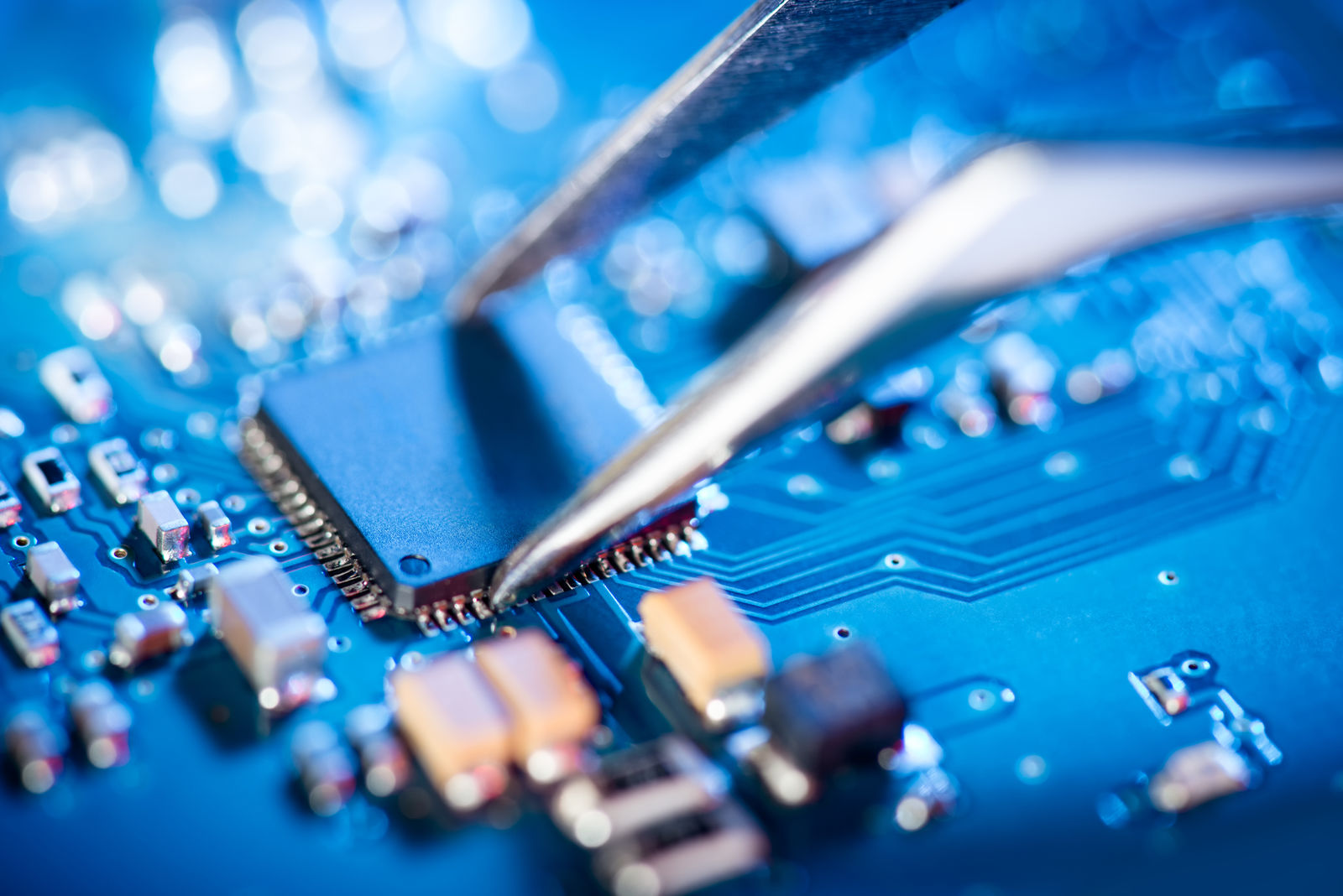

The semiconductor market is particularly volatile. Over the past few decades, periods of shortage and surplus have alternated rather abruptly. Supply chain expert Gerald Haas explains what lessons from the past can be applied to the current semiconductor crisis.

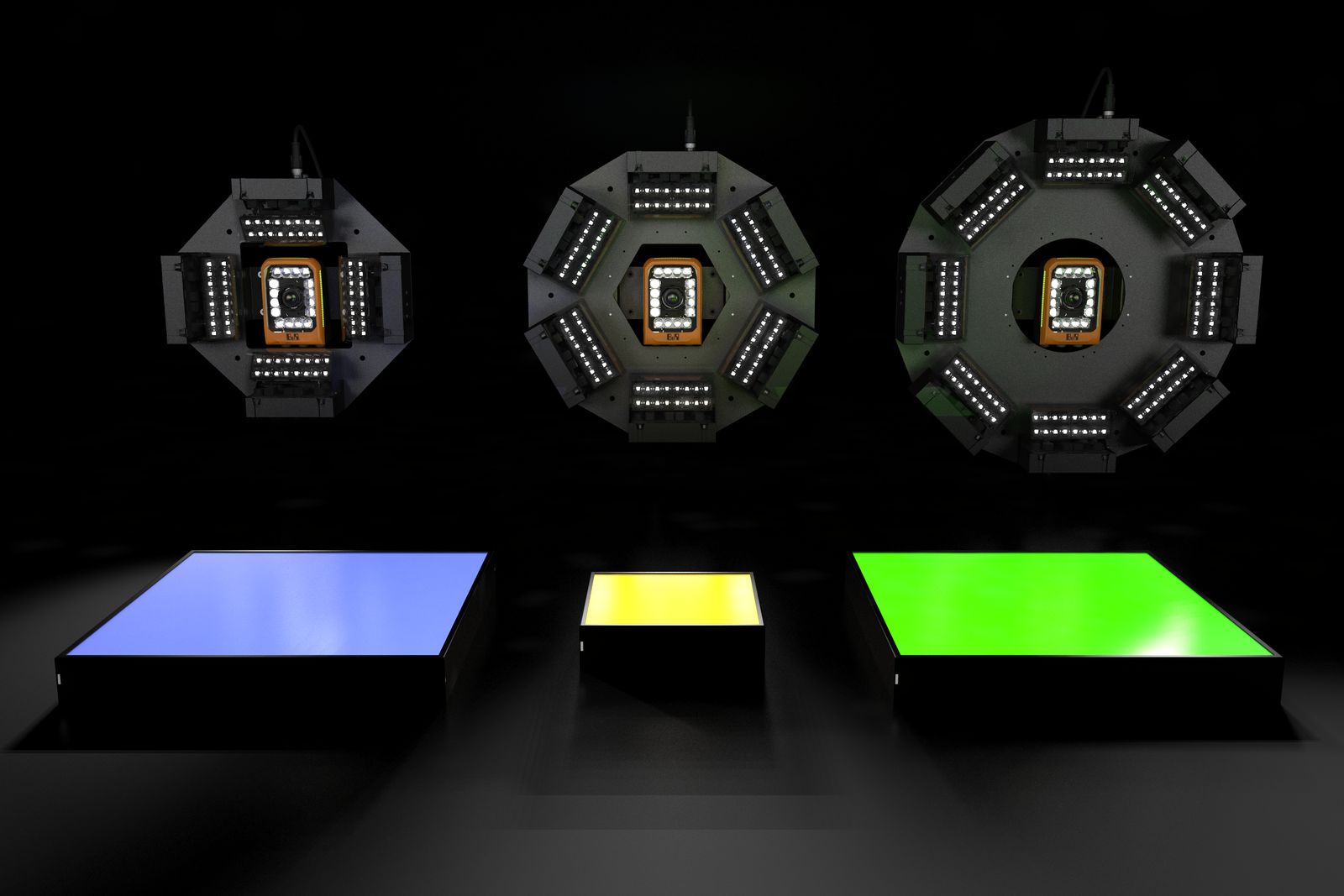

"I know of no other lighting system with such flexibility and precision"

October 2021

B&R has launched its own portfolio of integrated lighting technology. Machine vision expert Andreas Waldl explains why this was the only right choice and sheds light on the topic of integration.

B&R employees love a good challenge

September 2021

Jörg Theis has been CEO of B&R since April 1st, 2021. In this interview, the 51-year-old reveals what fascinates him about his employees, where he sees the company five years from now, and what other ABB divisions might learn from B&R.

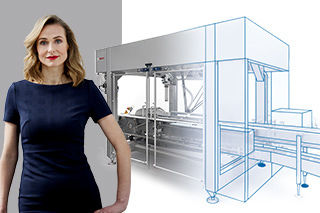

No more unpleasant surprises

September 2021

Beate Freyer, managing director of simulation company machineering, explains how digital twins ensure smooth operation and provide added value throughout the entire production process.

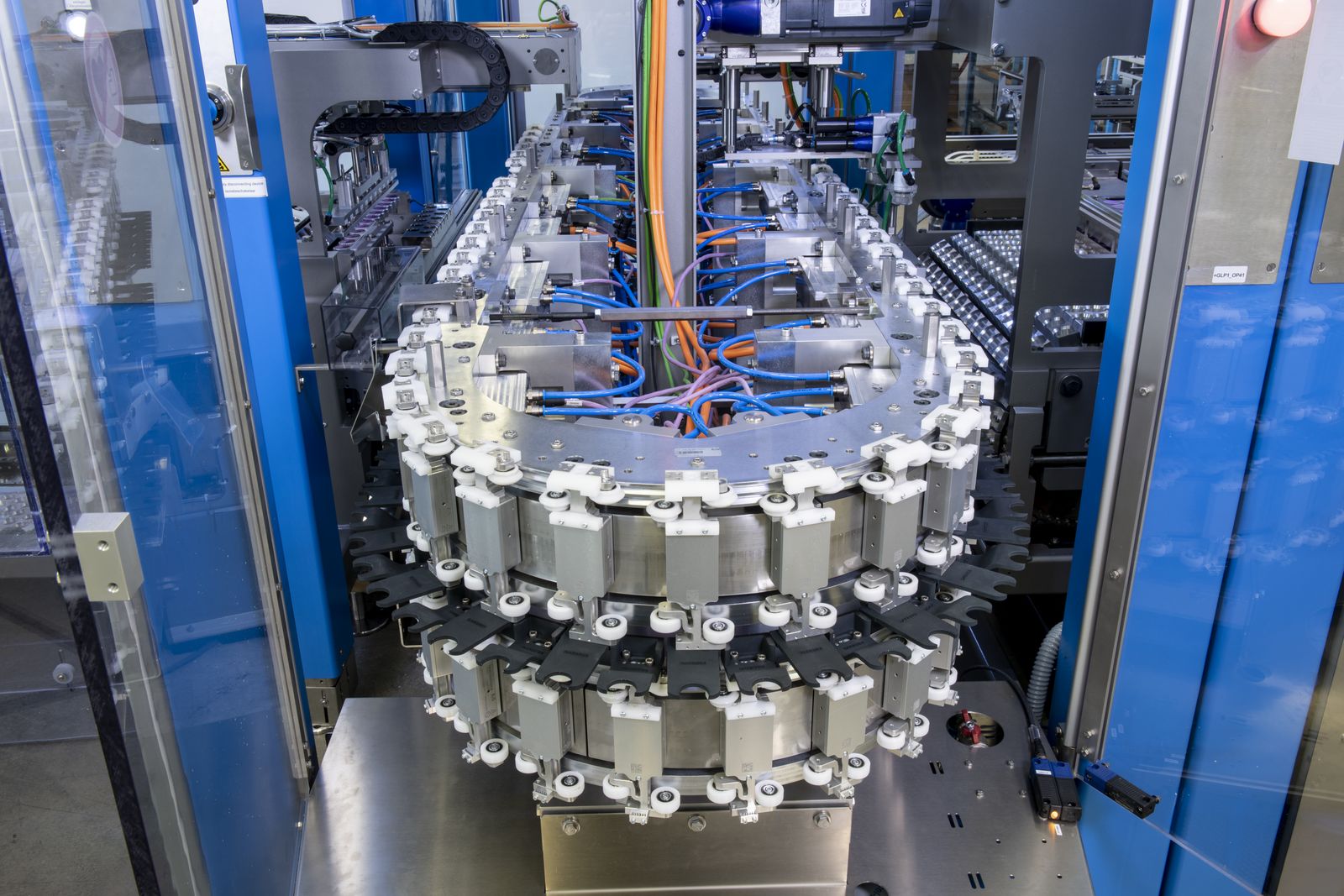

Mind the gap

September 2021

Connecting individual machine modules to form a continuous line can be a lot of work and take up a lot of space. Optima succeeded in creating a seamless transition using ACOPOStrak.

"We're going to turn the market upside-down with track technology"

August 2021

For the past five years, Johannes Vitzthum's life has revolved around track technology. Trained as a mechanical engineer, the young product manager has dedicated much of his career with heart and soul to this disruptive technology.

Putting flexible automation to the test

August 2021

Together with B&R, enders developed a solution that allows test benches for commercial vehicles to adapt flexibly to new testing scenarios – without any rewiring or reprogramming.

Will the cloud replace the PLC?

August 2021

For nearly half a century now, programmable logic controllers have played a central role in machine automation. But we're starting to hear the first voices claiming that new technologies like 5G, virtualization and the Internet of Things will shift all that control to the cloud. Today's three closing questions are directed at B&R's product manager for its X20 control and I/O system, Andreas Hager. How likely does he think it is that these predictions will come true?

The perfect match

June 2021

What role does simulation play in machine manufacturing and plant engineering? The answer is simple: It is the key to the next level of efficiency throughout every phase of a machine's lifecycle.

Smaller batches and 50% higher OEE

April 2021

Industry expert Fredrik Holmberg explains why small batches are such a big challenge for medical device assembly companies, and how adaptive manufacturing offers a solution that really pays off.

Three questions to the expert

April 2021

Is adaptive always better? What role does ACOPOS 6D play in adaptive manufacturing? How will current events shape the future of the CPG industry? Find out from Wlady Martino.

Concrete dreams

April 2021

3D printers are showing great promise in building construction, printing prefabricated components that are then transported to the construction site. A research project at the Technical University of Liberec in the Czech Republic aims to create a mobile robot that can print buildings directly on site. The team is using B&R controls, drives, HMI and software solutions to control the ground-breaking robot's sophisticated print head.

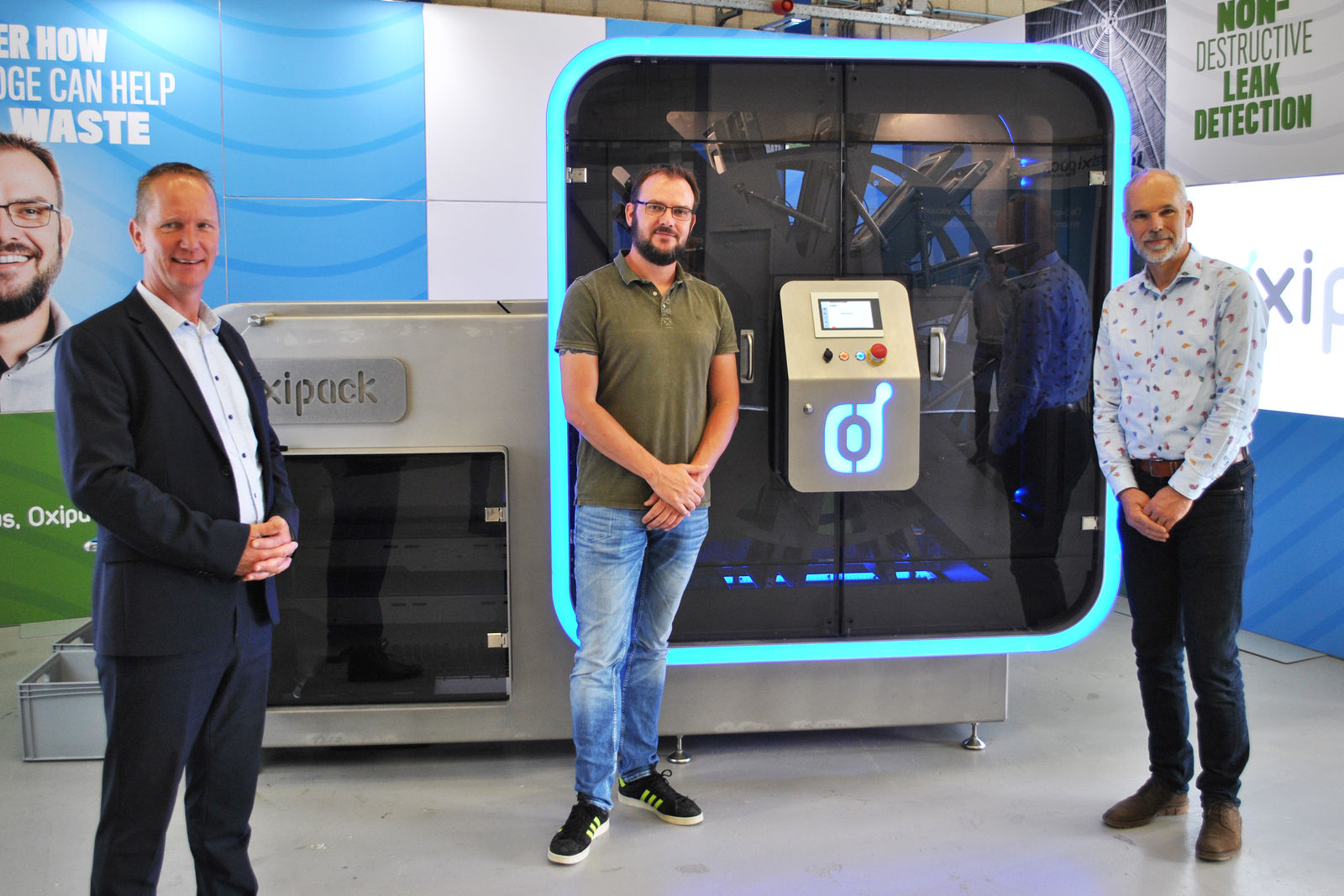

Quality revolves around efficient testing

March 2021

For foods and pharmaceuticals sealed in airtight packaging, leak testing is a critical step in the production process. Oxipack's new inspection unit, the Rotary, detects microscopic leaks without harming the product. Through close cooperation with machine builder Geurtsen and the control experts at B&R, the Dutch specialist's solution is efficient enough to test every item passing through the line

"They will complement each other"

March 2021

The youngest member of the OPC UA specification family – OPC UA Safety – enables safety communication in OPC UA networks. We sat down with B&R's safety expert Franz Kaufleitner to learn what the new standard has to offer and what implications it has for B&R's openSAFETY technology.

A new era of productivity

February 2021

Today's plants and machinery take up a lot of space. The time has come to break free from the limitations of one-dimensional product transport – and set the stage for a new era of productivity.

The world´s largest software ecosystem

January 2021

How do you bring IT and OT together? It's a question that must be answered by any company hoping to realize the visions of Industry 4.0. A puzzle – so far – without a real solution. But B&R is now bridging the IT/OT divide and offering machine builders access to the world's largest software ecosystem.

"An investment in robotics pays off faster than people expect"

November 2020

B&R is the world's first single-source supplier of controls and robotics. But what do they actually stand to gain from integrating robots into their machines? We sat down with robotics specialist Sebastian Brandstetter to find out.

Test bay of the future

November 2020

When you manufacture power supply systems, there's no avoiding the barrage of functional and safety testing to ensure that they are fit for use. To futureproof its testing performance, power supply maker Gustav Klein has developed an innovative new test bay. With its modular safety solution from B&R, Gustav Klein is able to manage many different test bay configurations in a single software project.

Compact cleanroom performance

October 2020

PIA Automation uses track technology in an innovative process module to assemble medical devices both inside and outside the cleanroom.

A change for the better

October 2020

In early 2014, an update to Germany's renewable energy legislation brought abrupt changes to the nation's biogas market. agriKomp took advantage of the situation to give its biogas plants a decisive upgrade: a completely new control solution from B&R. The company is more than pleased with the results: scalable solutions that are faster to develop and commission.

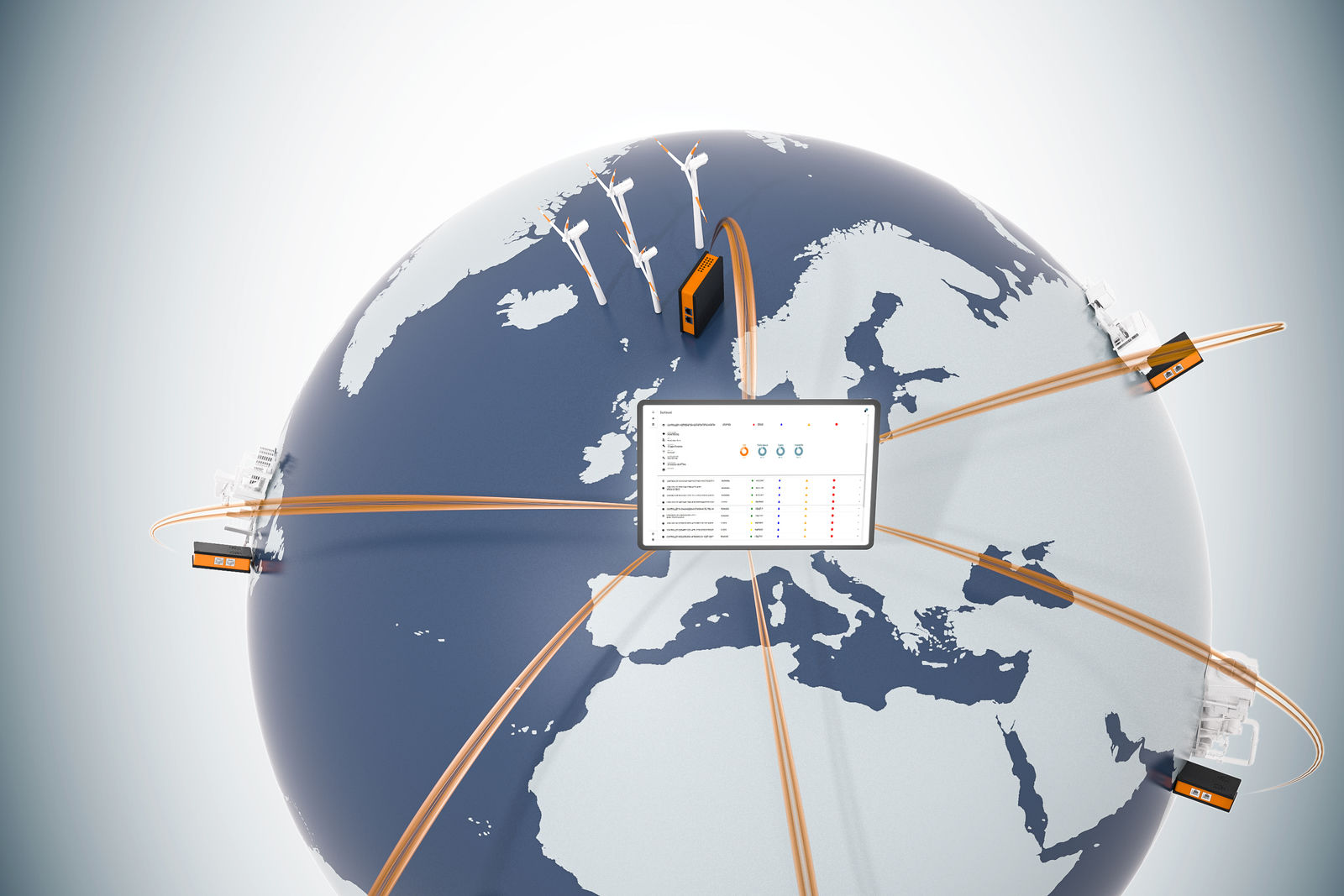

You don´t have to fly to get by

October 2020

Machine manufacturers must be well-prepared to service their customer's machines, and must react quickly when maintenance is required. With a remote maintenance solution, a connection can be established in no time.

Cutting costly copper waste

September 2020

Copper is an important, yet expensive, component of heat exchangers. For manufacturers of heat exchangers, minimizing copper waste is therefore a high priority. Together, Netto Electronics and B&R developed a solution that monitors copper consumption precisely and delivers serious savings.

A jarring performance boost

August 2020

Nordfish-Foodmark is committed to leveraging Industry 4.0 manufacturing technology to optimize its operations. To give its brownfield plants the necessary connectivity, the company evaluated a solution from B&R.

More productive pick-and-place

June 2020

Pick-and-place applications have traditionally had an upper limit to their productivity, because the robots and machines have operated as separate units. With the integration of robotics control into its automation system and introduction of a new software solution, B&R is now changing that.

Special purpose machines: Meat changing requirements

May 2020

For a special-purpose machine builder like Singer & Sohn, success depends on the ability to accommodate customer requests quickly and efficiently. That's why the food industry OEM relies on automation technology from B&R.

"OPC UA over TSN needs to be equipped for 20 years of evolving performance requirements."

April 2020

Initial testing has shown that OPC UA over TSN averages 18 times faster than existing industrial communication solutions, leading some in the industry to wonder whether such a dramatic leap is really necessary. To get to the bottom of this question, we spoke to one of the new technology's leading experts: Dietmar Bruckner.

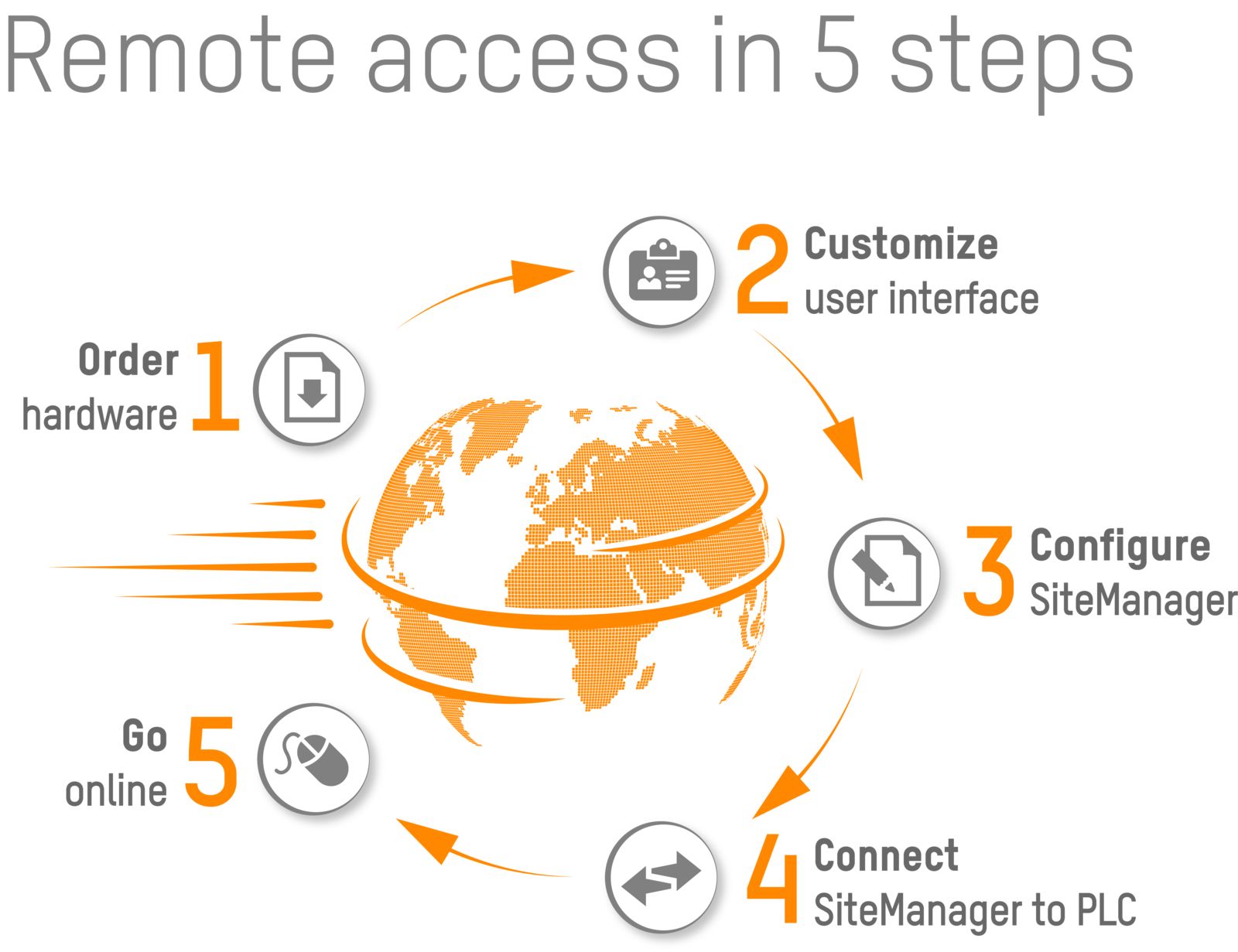

"Remote maintenance needn't be complex or costly"

April 2020

The market for industrial manufacturing technology is a global one. Modern communication and transportation make it possible to sell machines and plants to customers in all corners of the world. The task of maintaining those assets, however, can be a daunting challenge. We sat down with B&R's product manager for industrial IoT René Blaschke and had him walk us through the process of deploying B&R's Secure Remote Maintenance solution.

"The focus is on the customer and their needs"

April 2020

The integration of ABB robots into the B&R automation system is enabling entirely new approaches to machine automation. ABB's Gregor Kumm and B&R's Stefan Schönegger tell us what advantages the new solution brings.

One machine - countless possibilities

March 2020

The manufacturing industry requires machines that adapt to different products with little to no downtime or retooling. With today's automation technology, the dream of having one machine able to manufacture many different products is becoming a reality.

Single interface for seamless connectivity

November 2019

To implement their increasingly complex production processes, builders and operators of cutting-edge manufacturing systems will rely on a new generation of automation solutions.

Virtual meets reality

October 2019

When you rush through the construction of a new machine without thorough testing, you risk letting fundamental flaws in the design go unnoticed until commissioning. At that point, any changes to the finished machine are extremely costly and time consuming. That's why a growing number of machine builders are using simulated models – digital twins – to test and implement new machine designs quickly and cost effectively.

Autonomous agriculture

September 2019

If you imagine an agricultural landscape, you probably picture a field being worked by a farmer on his tractor. As the world's population continues to grow, however, there will be at least one big change to this scenario: While the special relationship between farmers and their equipment will continue, the machines out on the field will be handling much of the work on their own.

The next best thing to a crystal ball

June 2019

When a machine fails or has to be stopped for maintenance, it comes with a hefty price tag. And that's not just the cost of repair work and replacement parts, but rather the revenue that is lost every minute that a line is not productive. By helping to detect impending damage before it occurs, an investment in predictive maintenance can really pay off. In addition to preventing revenue loss, predictive maintenance extends the life of the machine and even opens up new business models.

A digital dialog with your machine

May 2019

Traditionally, once an OEM sells a machine, they are perfectly content to never hear from the buyer again – because that means the machine is running. How smoothly it is running is another question altogether. Beyond the occasional spare part or scheduled maintenance, contact with the customer – and any prospect of additional revenue – ends at delivery. That is all about to change, however.

Digital twins revolutionize time to market

April 2019

All across the world's markets and industries, products are moving from conceptual design to market release in a shorter and shorter amount of time. How long it takes to develop a machine's hardware and program its software can be a decisive factor in its success or failure against the competition. So, naturally – the faster, the better. Digital twins can play an important role in rapid development and testing of a machine's hardware and software. Digital twins revolutionize time to market

"Develop with confidence, commission with ease, perform with excellence"

March 2019

MapleSim is an advanced modeling tool from mathematics specialist Maplesoft that computes the physical forces experienced by complex mechanical systems. Partnership with B&R now makes it easier than ever to incorporate these models in B&R's Automation Studio engineering platform and on the machine itself as a digital twin. Chad Schmitke from Maplesoft and Kurt Zehetleitner from B&R explain the immedite payoff for machine builders as well as the long-term implications of this exciting technology.

Let there be light

March 2019

Lighting is a key element of any machine vision system. It determines if and how the camera sees the targeted object. In addition to the intensity, angle and wavelength of the beam, two factors that make all the difference are precise timing and intelligent control.

Previously unimaginable

March 2019

B&R is the first automation provider to fully integrate machine vision into its automation system. Product manager Andreas Waldl explains why so many machine builders are speechless the first time he describes what is possible with the new solution.

The dawn of a new standard

February 2019

Machines, field devices, ERP systems and cloud applications – all communicating on a single network? An impossible dream until only a few years ago, but with OPC UA over TSN, it will soon be reality. The world's automation companies have agreed on a common standard for real-time industrial communication.

From your brownfield to the cloud

February 2019

Existing plants rarely offer a way to collect machine data automatically. That's why B&R developed the Orange Box and has now equipped it with a cloud interface.

Cybersecurity for controllers

September 2018

Transferring data from the machine controller to the cloud requires a connection to the Internet. This makes it susceptible to cyberattacks. Machines with cloud connectivity need special protection.

"There is so much more to safety than simply shutting down the machine"

August 2018

B&R unveiled its groundbreaking integrated safety technology in 2008 under the banner of "Smart Safe Reaction". In the decade since, B&R has established itself among the world's most innovative manufacturers of programmable safety technology.

A unified network for automotive production

July 2018

OPC UA TSN turns a large group of isolated solutions with numerous interfaces into a homogeneous network for seamless communication across all systems and levels.

mapp Technology

July 2018

mapp Technology is revolutionizing the creation of software for industrial machinery and equipment. mapp components – mapps for short – are as easy to use as a smartphone app. Find out more about the future of sotware engineering.

Flexibility meets cost efficiency

June 2018

An intelligent transport system makes mass customization profitable. Personalized products such as custom-mixed smoothies can be produced cost efficiently.

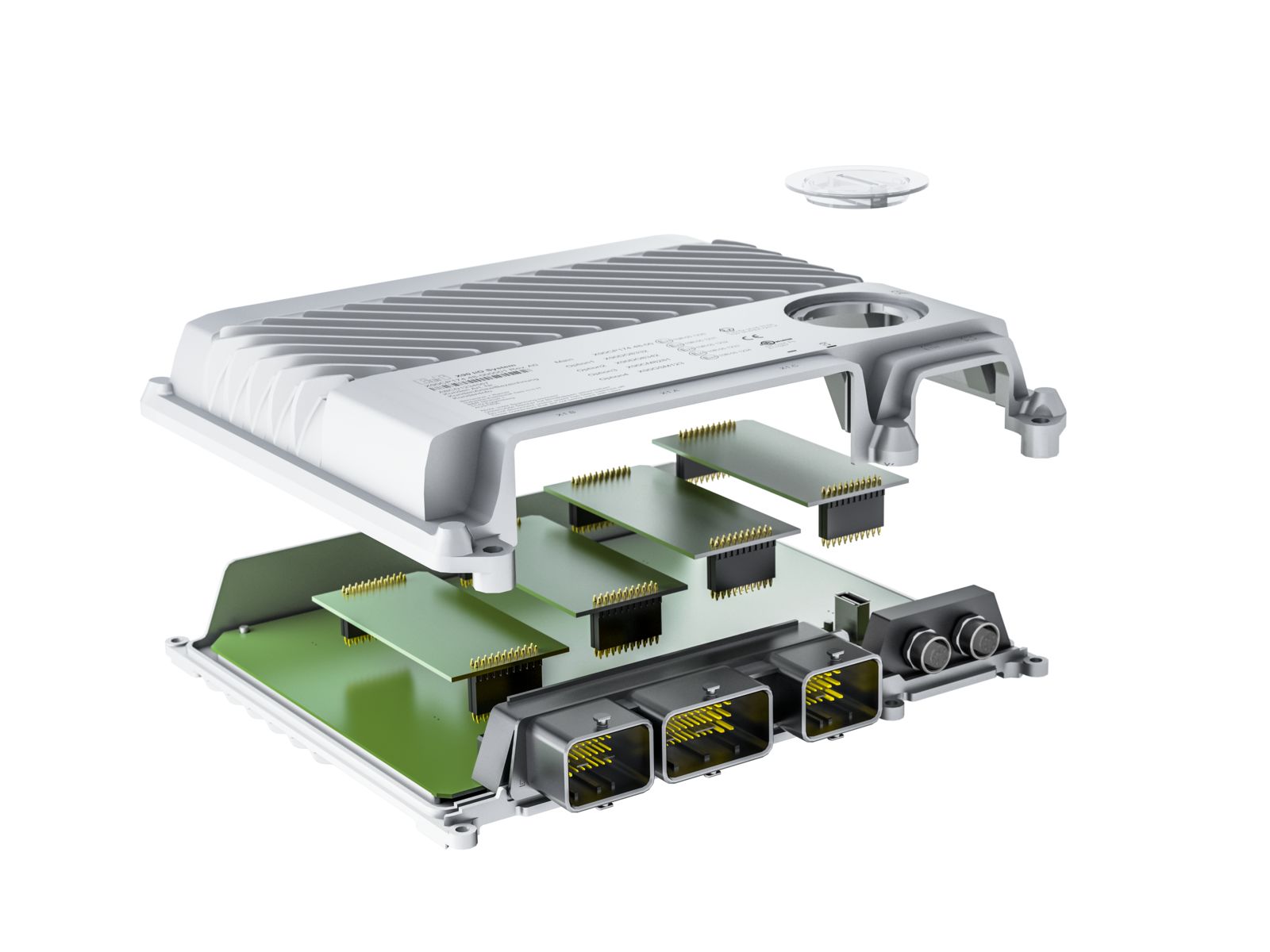

Safety for mobile machines

June 2018

These days, virtually every mobile machine now falls under the jurisdiction of the Machinery Directive. To avoid the high cost of developing their own safety solutions from scratch, manufacturers of mobile machinery seek out reliable technology partners for safety technology.

Two operating systems on one device

May 2018

In addition to their real-time operating system, many machines also need a general purpose operating system to perform tasks such as aggregating data and sending it to the cloud or to run computationally intensive HMI applications. With a bare-metal hypervisor, it is now possible to implement both systems on a single industrial PC.

Reliable giants

May 2018

Mining companies go to great expense to keep their excavators up and running, for every second of unscheduled downtime is a costly loss of productivity. The crucial reliability can be achieved much more cost-effectively through intelligent maintenance solutions.