Perfect solutions for plastics technology

B&R will be presenting complete automation solutions for production lines and plastics processing machines at the K trade fair taking place October 16-23, 2013 (Hall A11, Booth G26). Modular systems from B&R combined with perfectly matched components result in automation solutions that can be tailored exactly to the application at hand. This type of expertise is proving to be highly successful on the market: Each year, over 20,000 plastics machines with B&R controllers are put into operation worldwide.

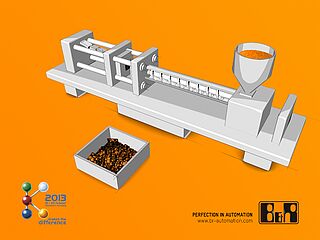

Complete systems from a single source

Automation Studio, the development environment from B&R, provides optimal support for designing modular machines and systems. Important processes for the plastics processing industry are included in technology packages. They make it possible to easily master even complex processes.

The use of integrated hydraulic control does away with the need for costly add-on devices, while integrating a robot or pick-and-place unit in the control system for the machine guarantees a significant reduction of cycle times. Standard packages for extruders and injection molding machines ensure that machine commissioning is handled efficiently. In addition, B&R will be taking the opportunity in Dusseldorf to demonstrate how advanced multi-touch technology can be used to easily and safely operate injection molding machines.

POWERLINK – Guaranteed performance for plastics machines

Real-time Ethernet POWERLINK has been established on the market for over ten years. This advanced technology – standardized in accordance with IEC requirements – allows an open platform to be combined with an integrated automation solution in order to achieve the advantages offered by a complete solution.

Built-in energy efficiency

Making effective use of energy starts in the machine's design phase. The Automation Studio development environment makes it easy to configure moving mechatronic devices and optimize motion profiles. At the K trade fair, B&R will be demonstrating energy-efficient drive solutions for plastics processing machines that also significantly reduce the amount of space required in the control cabinet.

Increased competitiveness with optimized production

A production plant produces a great deal of information that – if collected and used effectively – can increase the competitiveness of companies in the plastic processing industry. In Dusseldorf, B&R will be introducing APROL Factory Automation – a system for collecting and evaluating production data, machine states and energy consumption.