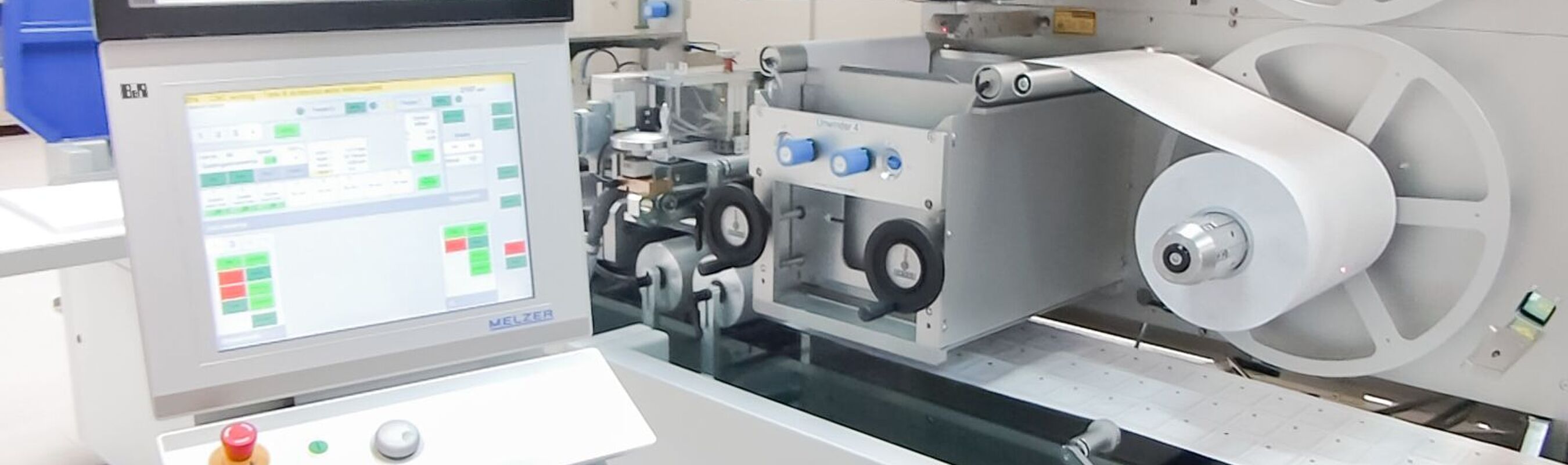

In addition to precision, Melzer machines are also characterized by flexibility, modularity and production speed. The performance of the smart label lines ranges from the entry-level SL-1 model with around 7,000 labels per hour to the high-performance SL-600 model with 60,000 tested products per hour. "With our intelligent production concept, we guarantee the customer the lowest unit costs for every order size," explains Melzer.

The drive and automation technology plays a decisive role in the performance of the machine. "With our smart label lines, precise and fast control of the hot melt heads and the feed in combination with the glue application of the pumps is crucial," says Melzer. A task that was so challenging for one of Melzer's former suppliers, a well-known German manufacturer of drive and control solutions, that they looked for an alternative.

When selecting the drives and controllers for the new Smart Label line, various automation manufacturers were tested. B&R stood out from the competition with its combination of performance and service.

With the previous drive systems provider, it was not possible to optimize quantity and quality in the smart label line at the same time. "With this manufacturer, we had a parameter that optimized the process for either accuracy or speed," Melzer recalls with a grin," – both were not possible. Only after changing to the drive system with B&R, could the system be bought into the desired clean and high-precision range," explains Melzer.

The new machine line requires the high-speed and precision control of a large number of axes – a task in which the servo drives and motors from B&R prove their capabilities. After the positive experience with the first project, Melzer decided to use the drives and automation technology from B&R for all future lines.