Eliminate the need for rigid service intervals without risking production downtime – that is the goal of condition monitoring systems. Together with automation specialist B&R, Wittmann Battenfeld developed such a system for its injection molding machines. Their motivation for doing so is clear: purchasing decisions are no longer based on a machine's price tag alone, but on the total costs over its entire lifecycle.

Together, the two companies Wittmann and Wittmann Battenfeld form the Wittmann Group – one of the world's leading manufacturers of injection molding machines, robots and peripheral equipment for the plastics processing industry. They operate a total of eight production plants in five countries and are represented at an additional 34 locations in all major plastics markets worldwide.

In the Lower Austrian town of Kottingbrunn, Wittmann Battenfeld builds injection molding machines with clamping forces ranging from 5 to 2,000 tons. Each year around 1,000 injection molding machines are produced there, 95% of which are exported to customers all around the world, primarily in the EU. The lion's share comes from the automotive industry (50 percent), medical production (15 percent) and the toy industry.

Automation specialist B&R is one of Wittmann Battenfeld's primary suppliers. The manufacturer has installed B&R machine controls in every injection molding machine built in the last 15 years. B&R's APROL software has been used for condition monitoring for almost three years now.

Intelligent condition monitoring for injection molders

Before switching to APROL solutions, Wittmann Battenfeld would check key sensors at scheduled intervals. Beyond continuing to use more and more sensors, what they also wanted was the ability to perform maintenance predictively. The goal was to use vibration sensing to identify potential machine and plant failures as early as possible – ideally before they even occur. Doing so would substantially reduce maintenance costs and increase availability. The right solution was found at B&R. Not only do the I/O modules reliably detect potential maintenance issues, they are also easy to configure and compatible with any controller topology.

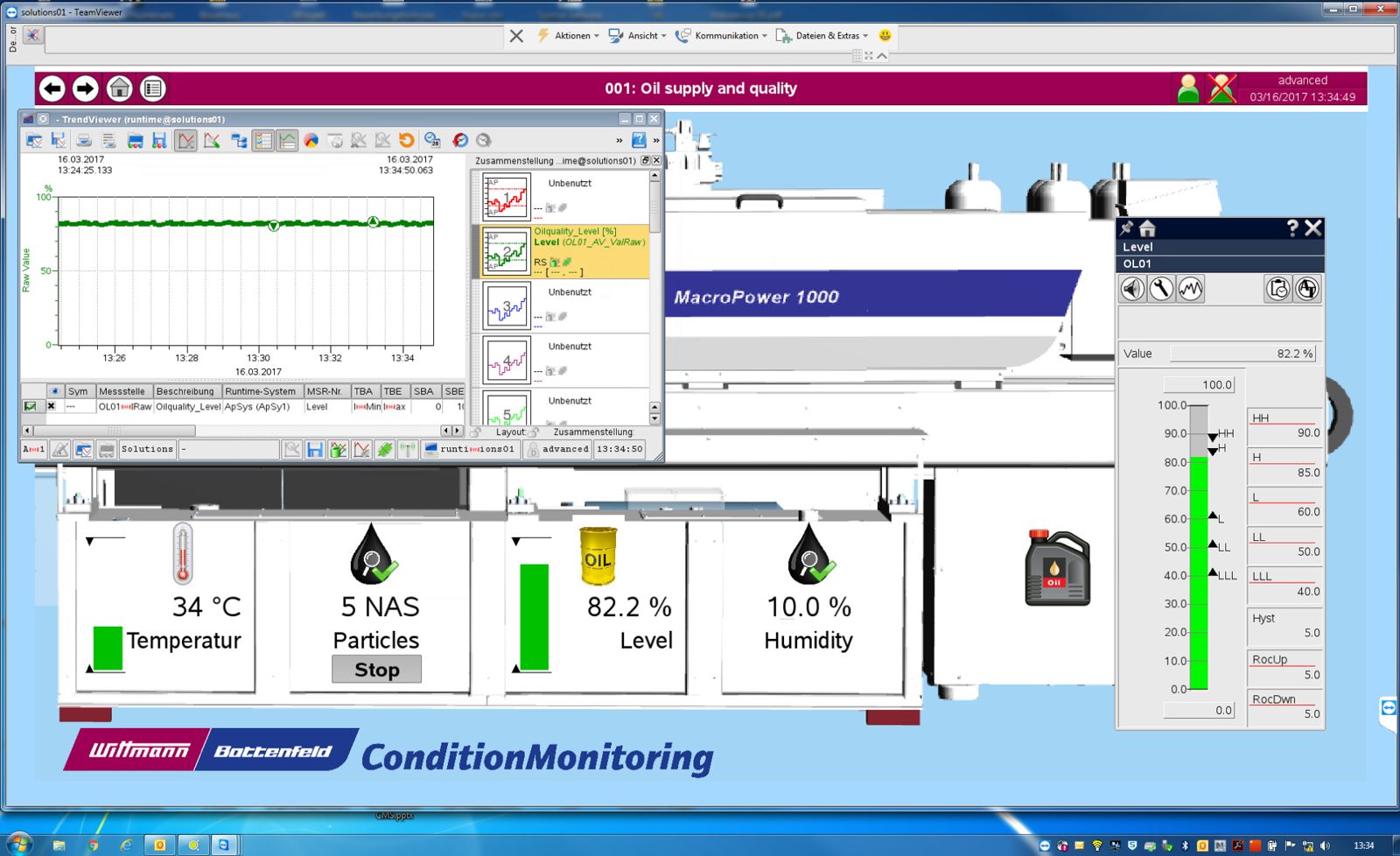

Condition monitoring is based on vibration analysis performed locally on the modules. The results provide detailed insight into the system mechanics and allow efficiently targeted optimization of existing processes. The injection molding machine manufacturer relies on this feature to detect contamination, such as when water gets into the oil. Although invisible to the naked eye, this kind of contamination can result in a defective pump within weeks. With an oil sensor system evaluated via APROL, this is now a thing of the past.

New opportunities with B&R's condition monitoring system

"What has long been common practice for wind turbines and refineries was an absolute novelty for injection molding machines, and we were the first to present condition monitoring at the 2016 K trade fair," says Dietmar Schabauer, head of technical customer service at Wittmann Battenfeld. "The greatest advantages will certainly go to customers with larger machines," says Schabauer. "In their case, the cost of a CMS system is more easily outweighed by what is saved in prevented downtime."

Project completion within a few months

Together with B&R, Wittmann Battenfeld was able to present a completed condition monitoring project within six months of the first meeting. "We had dedicated contacts at B&R and got active support throughout the entire project, including training. Since we were breaking new ground with this project, we were especially pleased that the cooperation with B&R worked so well," says Schabauer.

The rapid completion was made possible in part by the involvement of Wittmann Battenfeld's internal software development department. It was there that initial specifications were defined, such as which parameters were to be monitored, measured and evaluated. Developed in this way, the system is now continually updated and expanded to address new and changing customer requirements. "We wanted to monitor the oil and temperatures in the gearbox, for example, and to make some changes to the HMI. We wanted to view the sensor data for two machines side-by-side for direct comparison," says Schabauer. "At the same time, we made sure to stick to uniform standards to keep our long-term development costs sustainable."

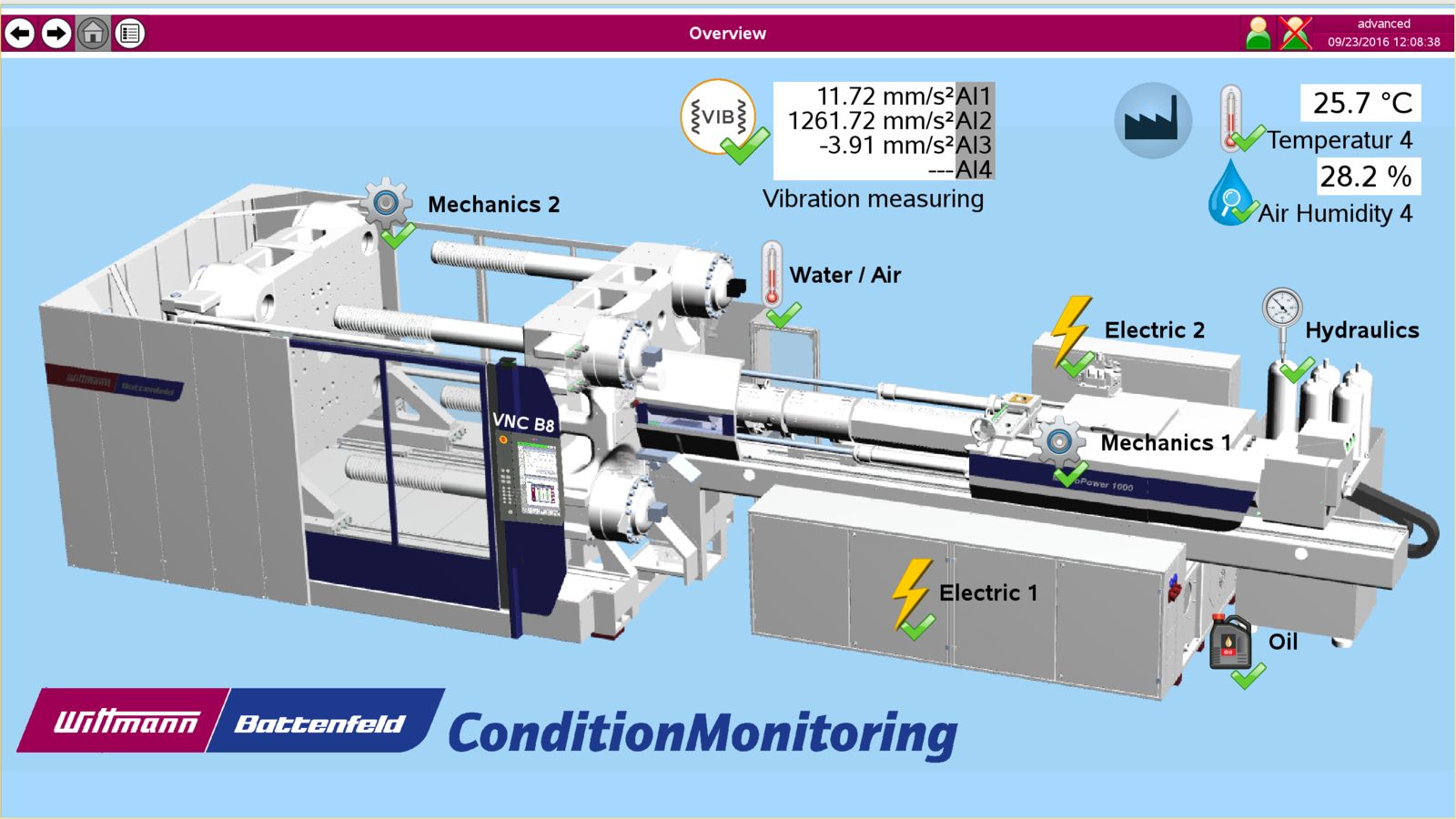

APROL for targeted analysis of measurements

Condition monitoring takes place in a three-level process. The first level is the collection of measurement data. Depending on the type of data, appropriate sensors are installed at specific measuring points to transmit the actual values to the analysis systems. It is possible to evaluate vibration, torque, temperature, humidity, oil quality, flow rate or screw functionality, as well as all the data from the control cabinet. At the second level, the collected data is analyzed and prepared. The heart of the CMS system is the evaluation unit, comprised of a CPU and a measuring module, which converts the measurements into analysis variables. The third level is where data evaluation and condition analysis are carried out.

It is currently possible to monitor and store around 80 different condition parameters for the machine. These values are stored on APROL servers for up to one year and can be retrieved and compared retrospectively – which is particularly helpful for service analytics. Until now, this system has been used by customers themselves as a stand-alone solution to monitor measured values on site. Wittmann Battenfeld's long-term goal, however, is to connect its machines to the Internet and send the recorded data to the customer via the cloud. This enables them to receive notification about various machine states, such as when oil needs to be changed or service is required.

CMS systems have become an integral part of the value chain

Condition monitoring has become an integral part of the value chain. Only systems that are able to transmit and analyze detailed data on wear and tear are able to forecast the remaining service life of plants, machinery and components.

"I worked as a service technician for ten years myself," recalls Schabauer. "In the past, you had to rely on your own senses and personal experience. Now every process is monitored digitally, and with much greater precision." Customers now also have the advantage that the machine's condition is monitored and evaluated automatically. If there are any changes in the measurements, they can be informed via email or text message. That way, they can carry out targeted maintenance without interrupting ongoing production.

It's all about lifecycle costs

"The prototype was extremely well received by the visitors at the 2016 K trade fair," Schabauer is pleased to report. "We were able to sell systems right from the start – before we had even defined a sales price."

This can clearly be attributed to a shift in focus among plant operators, who are thinking more than ever in terms of lifecycle costs. What matters is no longer just the purchase price of a machine, but all the costs that accumulate over its entire lifecycle. As a result, there is much more emphasis on keeping machines running consistently and efficiently. If the customer can be informed that maintenance will be needed in a few days, for example, they are able to incorporate that work into an already scheduled production changeover.

| Dietmar Schabauer Head of Technical Service, Wittmann Battenfeld "We had dedicated contacts at B&R and got active support throughout the entire project, including training. Since we were breaking new ground with this project, we were especially pleased that the cooperation with B&R worked so well." |