Integrating robots into a machine has historically been such a complex undertaking that many machine builders would rather avoid the topic all together. While they may have had good reason for this hesitation in the past, things have just gotten a whole lot easier now that ABB and B&R have jointly developed a solution that integrates ABB robots into the B&R machine control system.

Machine builders face increasing market pressure to make their machines simultaneously more flexible, more cost effective and more productive. What seem to be conflicting goals can be resolved using robots. The only catch: Robots typically require specific programming and are challenging to integrate into the machine's automation system.

"Robotics is a highly advanced discipline," explains Sebastian Brandstetter, B&R's product manager for integrated robotics. "Until now, however, robots and machines were independent systems." Robots have been a standard feature of large automobile production lines for decades, yet rarely can they be found as an integral component of a machine.

Two independent systems...

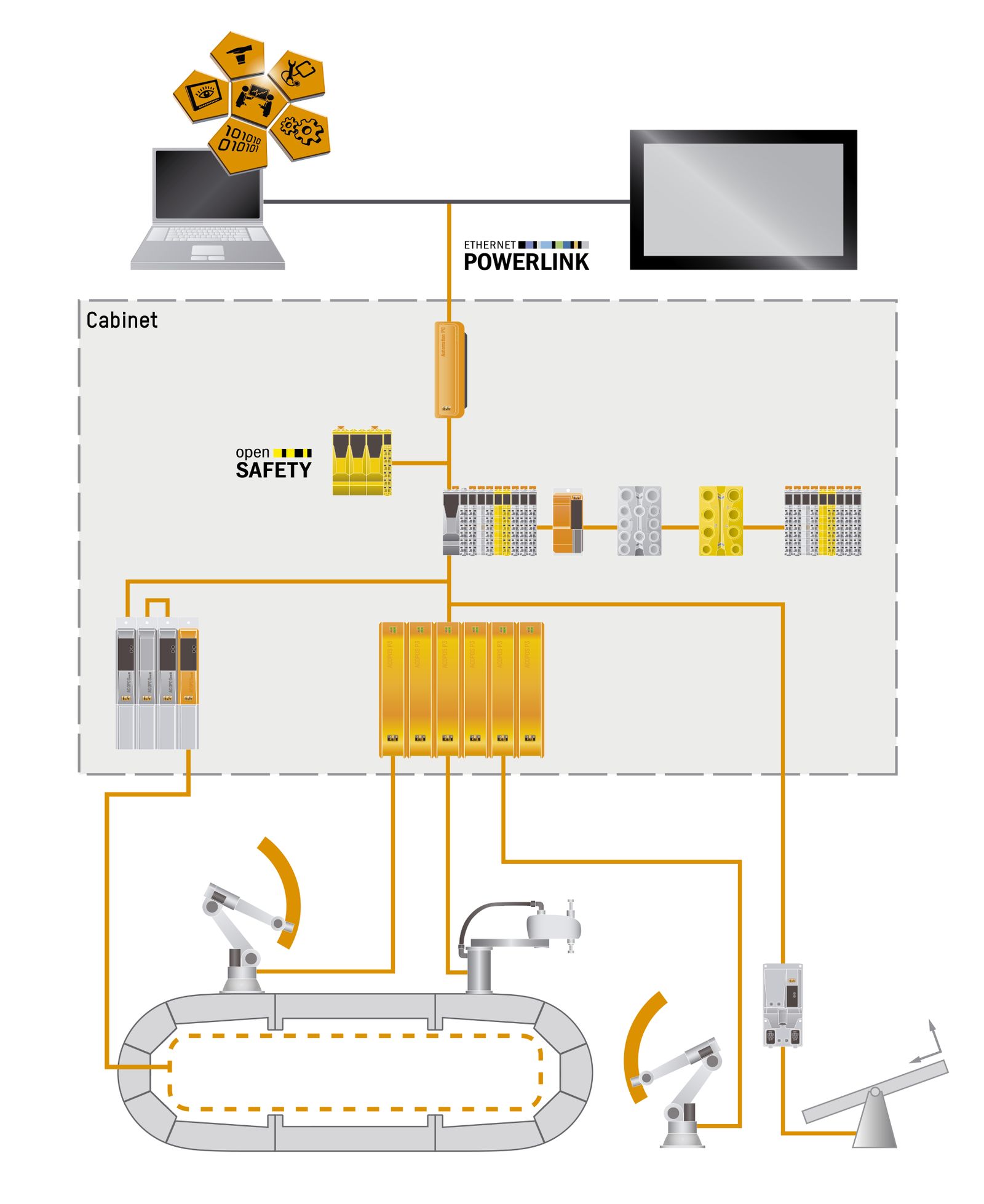

Some years ago, machine builders began integrating robots directly into the machine process to make their machines more flexible. Yet this flexibility came at a high cost, and the resulting synchronization left much to be desired. "A robot is a self-contained system," explains Brandstetter. It has its own controller and its own control cabinet. Engineering, diagnostics and maintenance are all performed using dedicated systems. Communication with the machine controller goes through an interface – which in many cases is even hardwired.

For those in search of a more expedient way to integrate robotics into a machine, the answer is clear: these two systems must meld into one. "We need to have one simple architecture," summarizes Brandstetter.

Sebastian Brandstetter, Product Manager - Integrated Robotics, B&R

…become one

"We now offer ABB robots as an integral part of our automation system," explains Brandstetter. Throughout engineering and operation, working with the robots is just the same as with any other B&R automation component. "For machine developers, it makes no difference whether they have to integrate a single motion control axis or an entire robot into the machine," notes Brandstetter. "The tools, the engineering environment, the B&R contact person: they're always the same."

A familiar environment

The integration eliminates the need for a dedicated robotics controller, a separate control cabinet and a specialist for a specific robotics language. The user has access to all the familiar machine programming languages like Ladder Diagram, Structured Text and C/C++.

In order to further facilitate the integration of ABB robots into machine automation solutions, B&R also provides pre-configured software modules that make robotics applications even easier for machine builders to create. B&R's mapp Robotics includes standard functions for control and commissioning as well as advanced functions such as feed-forward control, compressor and workspace monitoring. This allows the user to implement complex and highly dynamic applications without having to write countless lines of code. Development times are reduced dramatically.

Tight synchronization

"More user-friendly programming is a decisive advantage that comes from merging robotics with machine control," says Brandstetter. "Another key difference is the unprecedented precision that can be attained in the synchronization between the robot and other machine components." This becomes possible when you no longer need to use separate hardware, separate communication networks and separate applications.

The fact that all axes and sensors communicate on a common network increases precision to the previously unimaginable microsecond range. "This opens up a whole new world of possibilities," notes Brandstetter.

Parallel processing

A workpiece on a workpiece table, for example, used to be positioned and come to a complete stop before being machined by a robot. Now, the machining can take place while both table and robot are in motion. The machine application can automatically calculate optimized motion profiles and significantly reduce the overall processing time. Productivity goes up.

"Of course, the same principle also applies when you combine an ABB robot with a track system like ACOPOStrak," adds Brandstetter. The robot can process a workpiece while it moves at high speed along the track. The track becomes simply an additional axis that is included in the calculation of the motion profile.

Synchronization with sensors

Synchronization between sensors and robot motion also becomes easier. The result of a quality inspection with a B&R vision camera can be converted into a control command for the ABB robot in less than a millisecond. Defective workpieces can be removed from the line without any manual intervention or slowing down the manufacturing process. "This approach can significantly increase the machine's output," says Brandstetter.

Of course, the comprehensive simulation options available in the B&R system are available for the robotics as well. With a digital twin, the user can simulate and optimize the machine's entire motion sequence, including the robotics, before the machine is even built. Development becomes both faster and cheaper.