The trend toward smaller runs continues throughout the printing industry – and labels are no exception. To keep material waste and downtime between runs to a minimum, Nilpeter equipped its machines with a fully integrated machine vision system from B&R.

The printing market looks much different than it did even ten years ago. It has gone from long runs producing big batches to short runs with many changeovers each day. "Today, many customers need only a thousand labels, where they used to need 30 or 40 thousand at a time," notes Jesper Larsen, software development manager at Nilpeter. "Every second of production time lost while setting up for a new label type is a painful sacrifice."

To keep label printing profitable, it is also important to minimize the number of sheets that go to waste due to misprints. With the web racing through a Nilpeter printing machine at speeds of several meters per second, even the slightest imprecision will leave noticeable flaws on the printed labels. Such quality issues can cost dearly in terms of waste – something the Denmark-based machine builder knows all too well.

Challenges facing today's label printers:

- Shorter print runs increasingly common

- Valuable time lost setting up for new label types

- Costly material waste due to misprints

Increased precision

Nilpeter has worked with B&R for years, developing new solutions for automation and quality assurance. "We immediately recognized the advantages B&R's vision system would have for our printers. The insight it provides into processes like registration control can really help reduce waste," says Larsen.

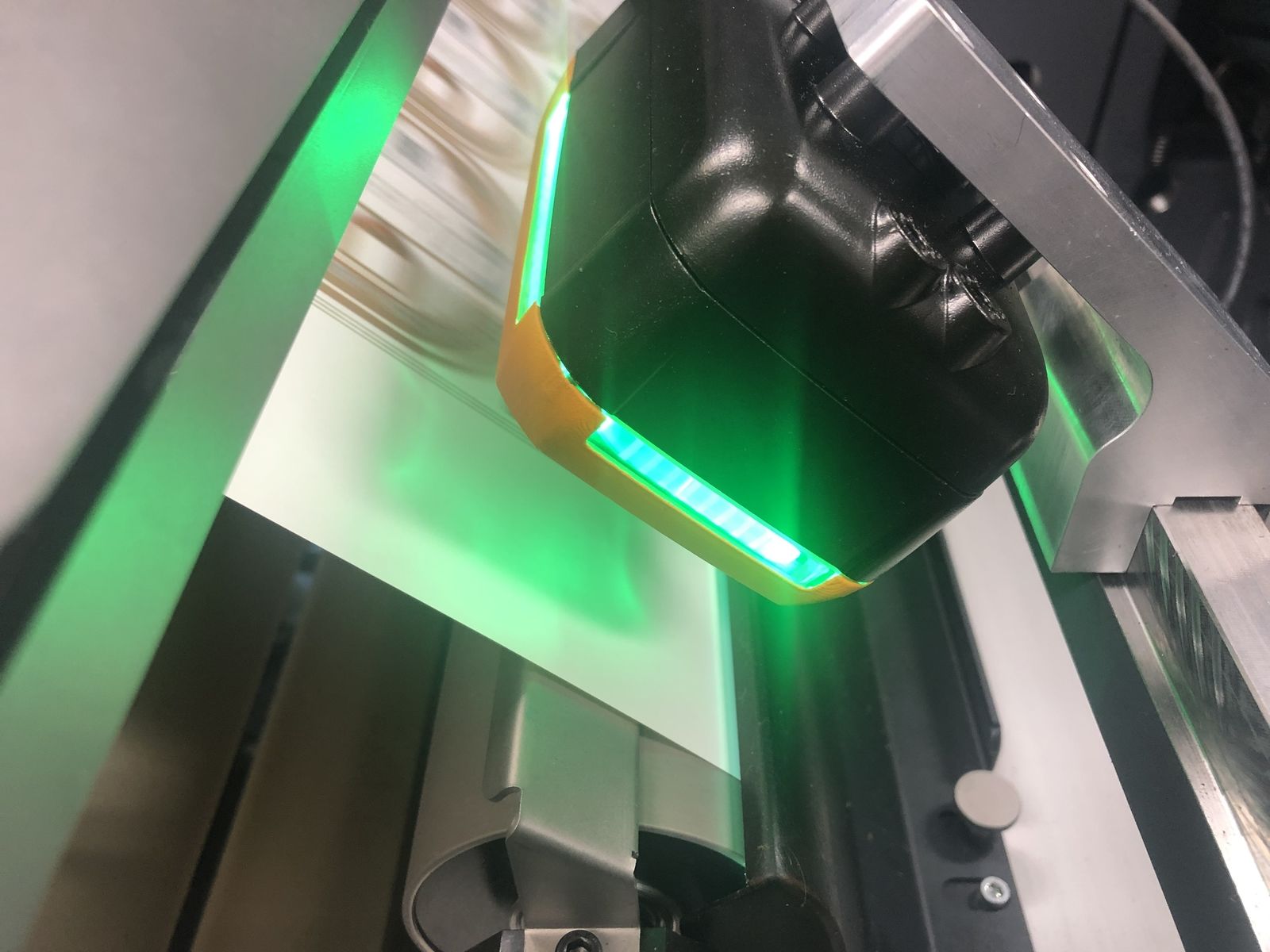

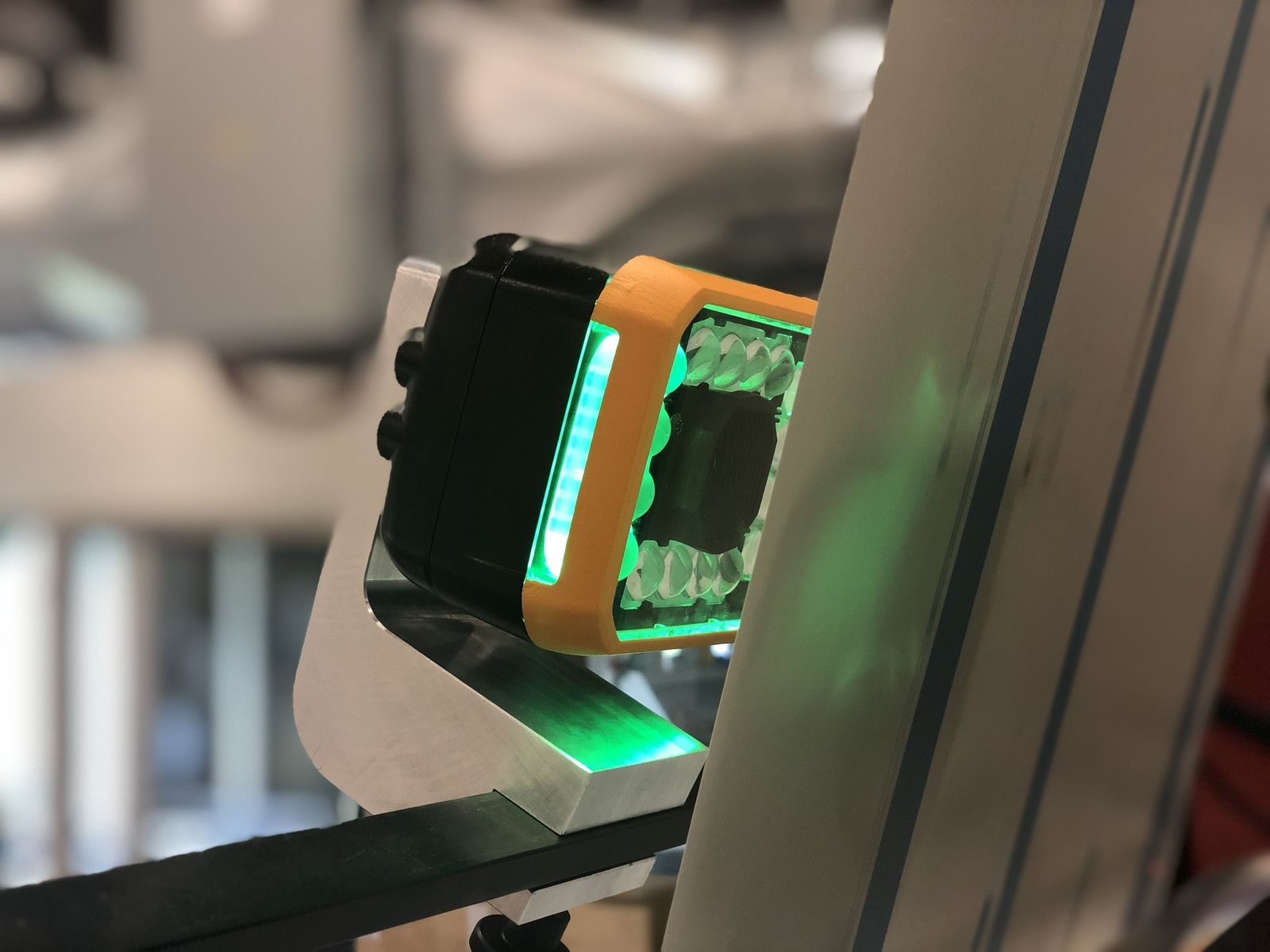

Nilpeter equipped each of its label printer's six units with a B&R machine vision camera. The cameras constantly monitor the position of the labels on the web. If the image processing software detects any imprecisions in the alignment of the colors, the camera alerts the machine control system, and the machine makes any necessary adjustments automatically.

Benefits for machine builders and their customers

Integrated machine vision makes Nilpeter machines more available and more productive. "You get smart, flexible batch production, and the single-cable solution means OEMs can get their machines to market faster," says Jensen, who sees great potential for integrated vision at Nilpeter. "With material expenses comprising such a large portion of the label printing costs," he explains, "it's exciting to imagine what can be gained by cutting waste in half." The integrated vision system from B&R makes Nilpeter one of the few companies in its market to offer a performance boost of this magnitude for its machines.

Advantages of B&R machine vision system for Nilpeter label printers:

- By helping reduce waste by 50%, the B&R machine vision system has made the machines substantially more profitable.

- B&R cameras detect color alignment problems with a precision of 12 µm.

- The printing machine can self-calibrate on the fly, without interrupting the printing process.

- The machine makes the necessary adjustments automatically.

- The lighting and color control integrated in B&R cameras ensures consistent, reliable results.

Jesper Larsen

Software Development Manager, Nilpeter A/S

"With material expenses comprising such a large portion of the label printing costs, it's exciting to imagine what can be gained by cutting waste in half."

Nilpeter has delivered label printing machines to the high-end segment for more than a century. Today, its customers can be found in the cosmetics, food and packaging industries.

| B&R's vision technology provides both hair-splitting accuracy and high flexibility to handle product variations. The fact that it is fully integrated means that control of the camera, lighting and colors is all right there in the machine control system with all the other automation. All the components communicate on the same network in real time. |