For B&R customers, implementing machine vision functions in new or existing manufacturing systems no longer comes with the prohibitive overhead in time and costs. Among the first to offer its customers a solution based on B&R's integrated machine vision technology is Spilker, manufacturer of punch presses and complete lines for the printing, labeling, automotive, pharmaceutical and packaging industries.

"B&R's integrated machine vision system and the functions it enabled us to implement are an absolute highlight of our pilot system," reports Spilker sales manager Mark Possekel. "Usually, however, such highlights come with a bitter aftertaste when you realize how much they cost. That's where this solution is different – regardless of whether it's a new development or a retrofit. It's great for our customers, which of course is great for us."

These praises were echoed by customers who got a first look at the new vision solution at the 2019 ICE exhibition for paper, film and foil converting in Munich. For Possekel, the positive feedback was certainly pleasing, if not surprising – after all, the solution is a perfect fit for what many Spilker customers had been requesting.

Demand for vision functions on the rise

Spilker found its niche creating custom converting machines and punch presses. For Possekele and Managing Director Heinrik Spilker, expanding on the company's years of automation know-how with a more in-depth approach to machine vision was an obvious step. The exhibition offered the perfect opportunity to present the first applications yielded by the endeavor.

After evaluating numerous potential suppliers, the company selected two products for its pilot system. In addition to the B&R solution, the pilot system also featured an inspection solution from a well-known specialist in the area of quality assurance for web processing.

"What's good about the inspection system are its preprogrammed standard functions, including pressure control and the ability to compare live images against predefined images of an ideal product. On top of that, it's also very easy to operate," adds Dirk Starke, programmer and automation specialist at Spilker. "The downside, though, is that it only tells you whether the product is good or bad, without providing the underlying measurements, which can only be obtained indirectly and at much higher cost. It also lacks an interface for direct communication with the line controller."

Conventional vision systems: Too complex

Seeking to help its customers cope with increasingly stringent requirements for documentation and quality assurance, Spilker also evaluated suppliers of conventional machine vision solutions. "These suppliers offer systems in our price range that provide measurements we can use as setpoints in our processing stations or pass on to our customers for their documentation," explains Possekel. "The problem with these standalone and PC-based solutions, however, is the difficulty of integrating them into the machine control environment. They also require intensive training and becoming accustomed to a new engineering environment. Especially with the exhibition rapidly approaching, that could have easily become a problem."

A stroke of luck: Integrated vision from B&R

Understandably, Spilker's experts took notice when they heard B&R was working on a machine vision solution. The machine builder had been using B&R's seamlessly integrated automation portfolio to develop their own automation solutions in-house rather than relying on external partners. That meant its developers were already comfortable working with B&R products and using the Automation Studio engineering environment – which is also where they would be configuring the camera.

"The announcement from B&R came as a stroke of luck for us," recalls Spilker. "We immediately volunteered to serve as a pilot customer. There are plenty of vision systems on the market, but a package like B&R's – which is on the one hand extremely powerful, yet also suitable for newcomers to vision technology and unbelievably easy and inexpensive to integrate – that is rare."

After preliminary discussions with the local B&R office, where Spilker presented the production task envisioned for the exhibition demo and the measurements that would be required, things progressed quickly.

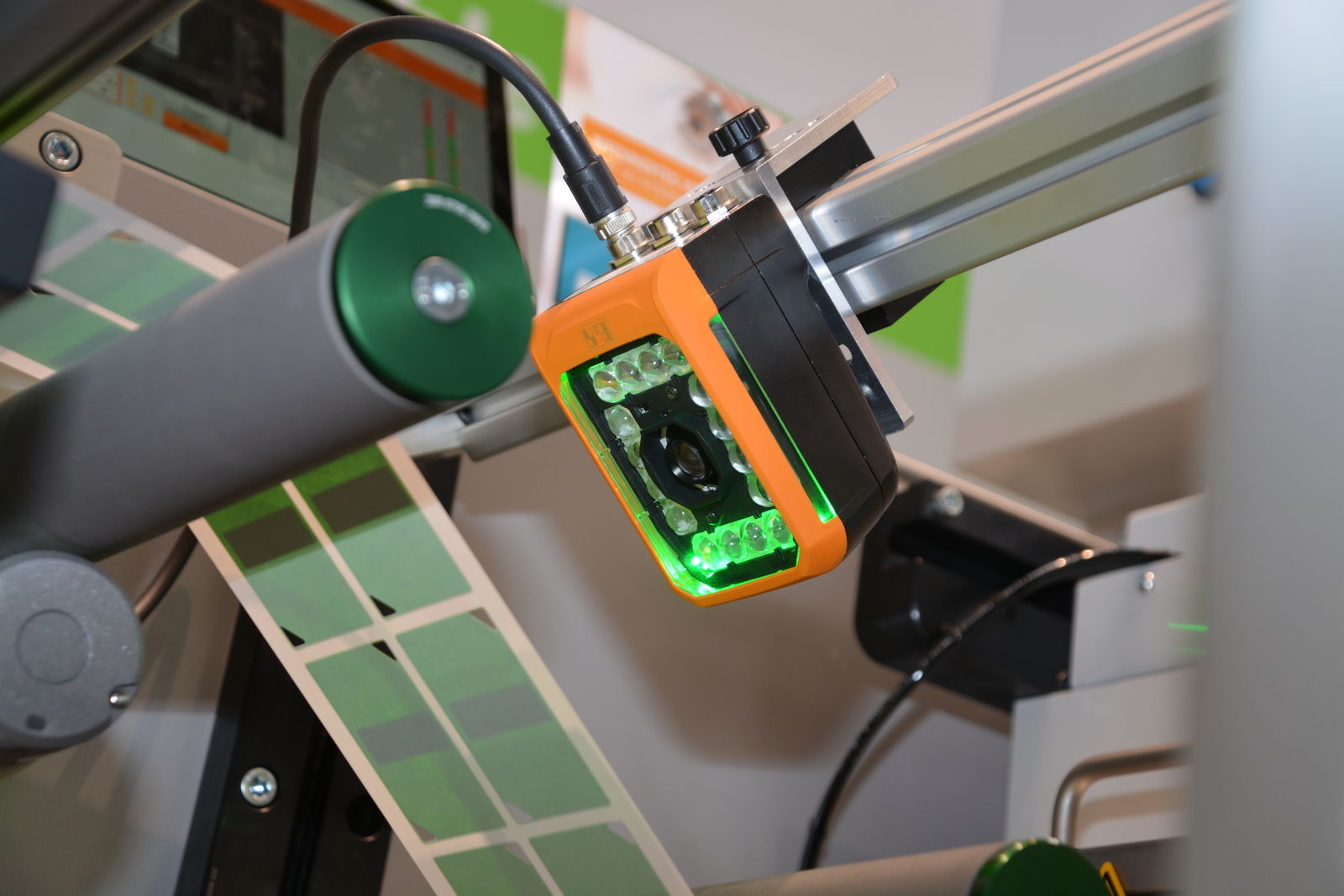

"B&R's vision experts recommended a 1.3 megapixel Smart Sensor with integrated lighting," describes Spilker. "And we followed that recommendation."

Integrated lighting and image processing

Image processing is performed entirely in the sensor, leaving only the evaluation of the inspection results up to the machine controller. Triggering precision of only one millisecond allows Spilker to design very tight control loops for monitoring and adjusting punch position – further increasing process stability. The 16 built-in high-performance LEDs operate with exposure times well below 100 milliseconds. Short exposures minimize interference from external light sources, reduce image processing time and make it possible to capture fast-moving objects. The Smart Sensor comes equipped with a variety of vision functions, including code reading, blob analysis, matching, OCR and measurement.

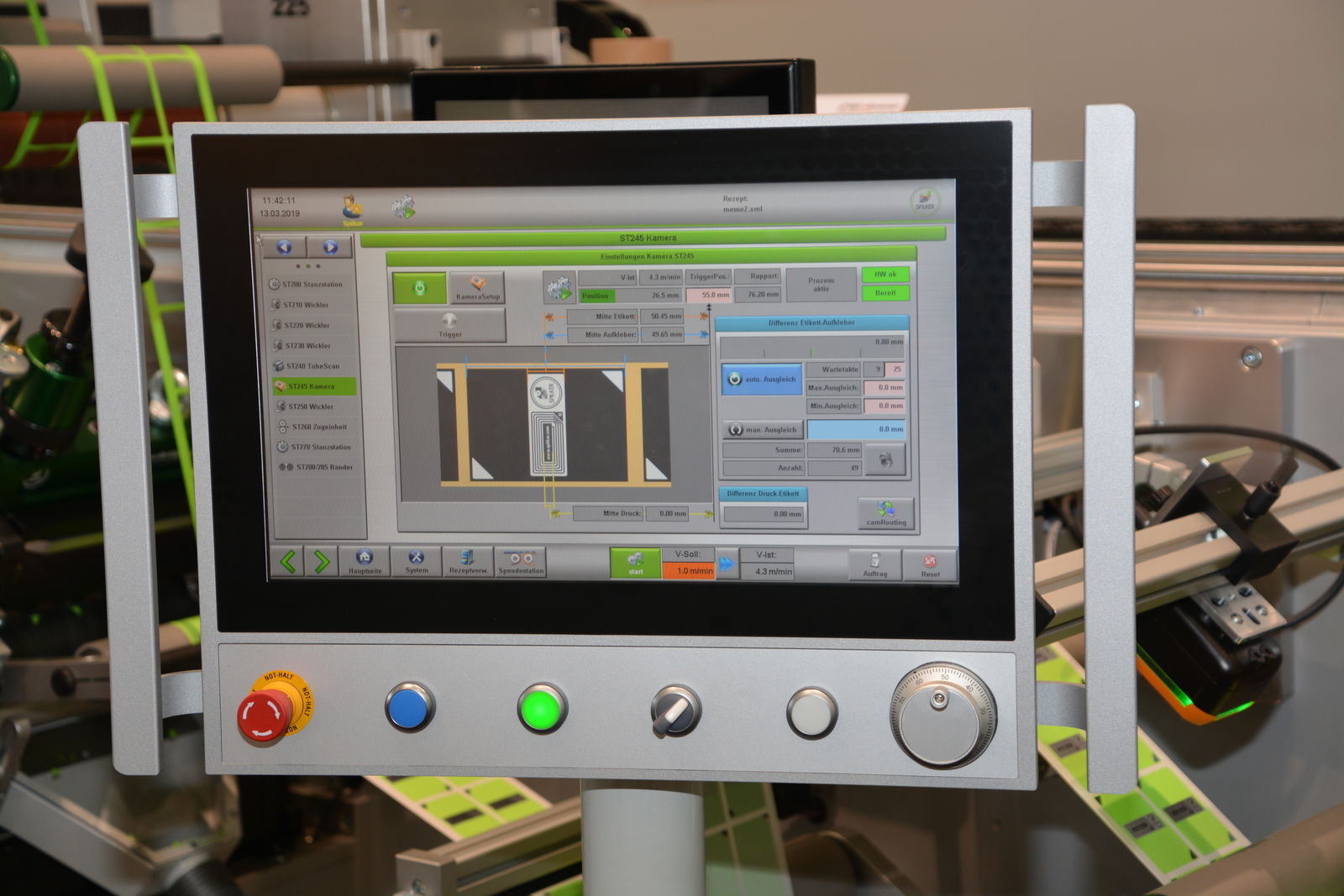

To further eas Spilker's learning curve with the new camera system and accelerate development, B&R provided Starke's team with additional support. Within hours, they had made rough settings based on production samples and used the vision system's integrated matching function to set up a number of required measurement functions. On the pilot system, these functions deliver three position parameters. If the deviation grows too large, the tools at the processing stations are adjusted accordingly.

On the pilot system, 50 x 70 millimeter self-adhesive labels are rotary-punched two at a time in a roll-to-roll process, with additional holes then punched in two places before a sticker is applied. Machine components such as the winder, cross cutter and rotary die cutter are mounted on the back panel of the machine. The open machine layout provides easy access to individual components, maximal insight into the production process and makes it easy to mount the Smart Sensor.

Integral component of Automation Studio

Since the Smart Sensor is integrated directly into the engineering environment for the controller and communicates via OPC UA, there are no interfaces to be programmed. With position, orientation and other data available to the controller in real time, the drives are able to react quickly and precisely to any deviations.

"We developed the routines for processing measurements from the Smart Sensor in the controller, programmed the control loops and the visualization of the machine vision functions in the machine's HMI application," says Starke. "Working with the Smart Sensor confirmed that it is a highly integrated solution that is seamlessly incorporated in B&R's engineering landscape and tailored to the needs of automation developers."

Done in days

This fact was borne out by the extremely short implementation time. All together, it took the B&R experts and Spilker's team less than four days to get the pilot system's vision functions up and running. And the functions performed perfectly the first time they started up the system.

In light of the positive experience and the praise received from exhibition visitors, Starke is confident that B&R machine vision will play an important role in the future of his company. "Particularly in cases where conventional sensors run up against their limits – detecting complex error scenarios or capturing positions – the Smart Sensor is the perfect solution to have in our portfolio."

| Henrik Spilker Managing Director, Spilker GmbH "B&R's entry into the machine vision market was an absolute stroke of luck for us, because many of our customers had been requesting vision functions for their printing, labeling and converting equipment. It was especially lucky that the B&R package manages to be both extremely powerful, yet also inexpensive and suitable for newcomers to the technology." |

Extensive machine vision functions

B&R's mapp Vision software solution includes an extensive selection of machine vision functions, encapsulated in easily configurable software blocks. There's no need for the programming work that would traditionally be necessary.

- Code detection (identification)

- mapp Vision can handle more than 40 different code types, including all the most common 1D and 2D codes. The function is self-optimizing and enables reliable results even at very high speeds.

- Text detection (OCR)

- The integrated character recognition function works with a deep learning algorithm. The OCR function is therefore very reliable and enables high-speed reading even with poor image quality.

- Shape detection (blob)

- Shape detection determines the size of the shape and its center of gravity with micropixel precision. It also provides information about orientation and average grey value.

- Object comparison (matching)

- The matching function easily identifies objects, their position and orientation. In addition to edge-based matching, a correlation-based variant is also available.

- Measurement (metrology)

- With Metrology, mapp Vision provides a powerful and highly accurate measuring instrument. Edges along lines or circle segments are measured with subpixel accuracy.