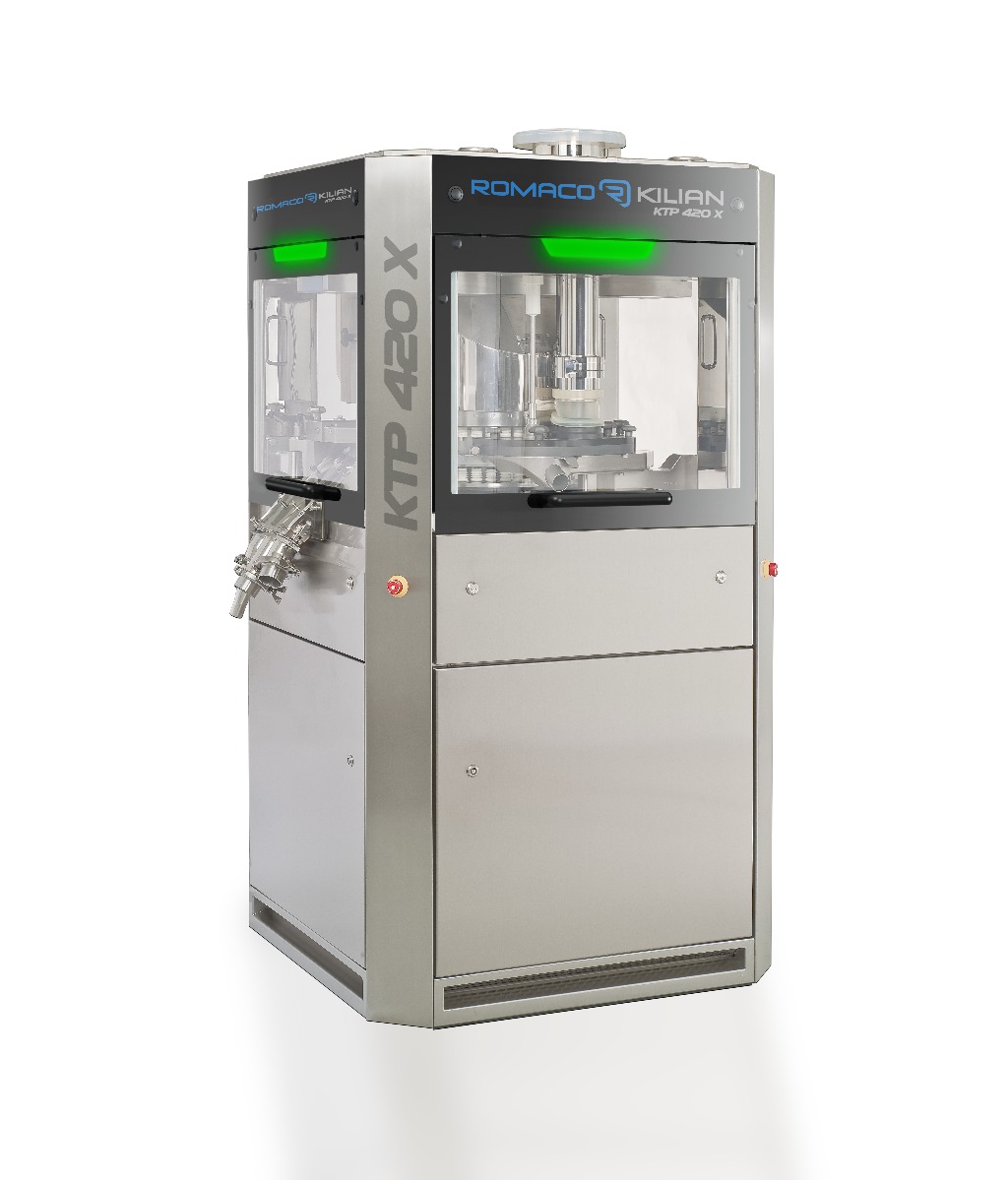

Kilian Tableting didn't waste any time after its integration into the Romaco Group. By the end of the fiscal year, the company had outpaced its own goals and posted a 15% increase in order volume. This success was in no small part due to the new KTP420X rotary tablet press, the first representative of the Kilian portfolio to debut the new design, featuring a completely revamped HMI system based on B&R technology.

Premiering at Interpack 2014, Kilian's new KTP420X rotary tablet press turned more than a few heads with an innovative design that stood out from the crowd. Several of those heads belonged to a panel of experts – who presented it with the 2014 iF product design award.

Although it causes its fair share of double-takes, a single glance is enough to appreciate the simple elegance of the tablet press. The combination of stainless steel and tinted glass – accentuated by stylish light strips that indicate the machine's status – is a statement of progressive design and premium quality. The 21.5" display of the new operator panel, based on a hygienic stainless steel model of B&R's Automation Panel, perfectly complements the machine's functional beauty. The HMI software runs on a powerful Automation PC 910 with a dual-core i7 processor.

Total package

"We closely examined HMI products from a number of suppliers," says Kilian's chief technology officer Jens Carstens. "B&R offered by far the best total package for our application."

The machine builder was looking for a 21.5" Full HD multi-touch display to provide ample space for a clearly structured user interface.

"At the time, B&R had not yet released a 21.5" model," remembers Carstens. "With only weeks remaining until Interpack, B&R accepted the challenge and delivered four prototypes – ahead of schedule. Very impressive!"

Hygienic design

B&R's developers created an open-backed stainless steel HMI housing that can either be mounted on a swing arm or built into a remote operator terminal.

Since Kilian planned for the new HMI to be used in all types of machines and industries, hygiene standards played a prominent role in the specifications. With no dirt-collecting gaps and a shatter protection membrane over the touch screen, B&R's solution hit the mark here as well. The new solution is perfectly suited for use in the food & beverage and pharmaceutical industries.

The newly designed HMI system with gesture control is based on a powerful Automation PC 910 with a dual-core i7 processor and a hygienic Automation Panel with a 21.5" display. (Source: Franz Roßmann)

Illuminated ring keys with tactile feedback

An E-stop button and four illuminated ring keys for frequently used functions are integrated along the bottom of the display. "We've stopped using virtual keys for the most heavily used functions because of the visible wear we encountered with our previous system," explains Carstens. "Unlike virtual keys, the hardware keys also provide tactile feedback, which has benefits such as allowing operators to keep their eye on the machine when working in jog mode." In addition to the illuminated ring keys, the display also has an integrated RFID receiver, which Kilian plans to use for access control and rights management in the future.

To complement the sophisticated hardware design, Kilian also worked with a UI design specialist to create a state-of-the-art user interface based on a comprehensive analysis of operator behavior.

Commanding performance for demanding applications: APC 910

Regarding the lengths that Kilian went to in developing the user interface, the CTO explains: "The expectations that today's users have for production machinery interfaces are shaped by their experience with smartphones and tablets. In addition to highly intuitive operation in general, they expect fast responses when switching between screens or displaying system messages.

Kilian recognized early on that they would want the new HMI system to offer gesture control options. Extensive comparison testing with numerous industrial PCs showed that the swiping gesture in particular places very high demands on computing and graphics performance. B&R's Automation PC 910 emerged as the clear winner in this category as well.

Real-time data for every tablet

The sheer volume of data produced by a tablet press is demanding on the HMI. The KTP420X produces up to 360,000 tablets per hour, and the maximum pressing force for each and every one is monitored, recorded and displayed in real time for quality assurance and traceability. In combination with the extensive variety of configuration and parameter settings – such as different test sampling methods – this volume of data makes the HMI application very complex.

The Automation Panel 900 communicates with the Automation PC 910 via SDL3. Not only does this communication standard guarantee minimal latency, it has also reduced the number of connection cables Kilian needs and given them greater freedom in the positioning of the HMI unit.

Uncompromisingly robust industrial PC

The industrial PC platform for the HMI application – which was written in C# and the .NET framework using WPF – operates fan-free in spite of the powerful performance it offers. With applications and data all stored on a high-speed 128 GB solid-state drive, the Automation PC has no rotating parts and ensures minimal latency. "The flexible options for mounting orientation are a clear advantage of B&R's industrial PC," adds Carstens. Like in the previous version of the machine, Kilian uses an OPC interface between the control and HMI applications, which simplified the transition to the new HMI system as well allowing for easy integration into higher level systems.

With its fresh design and new HMI system – as well as numerous improved details – Carstens is proud to report that the KTP420X has been well received by its users: "The first machines were sold before the fair was even over. We've already exceeded our sales goals for the first quarter of 2015, and the KTP420X has had a lot to do with that."

"We closely examined HMI products from a number of suppliers. B&R offered by far the best total package for our application." Jens Carstens, CTO, Kilian Tableting GmbH

Kilian sets course for growth with B&R

The success story continues. At ACHEMA 2015, Kilian unveiled the next machine to equipped with the new HMI system: A bi-layer rotary press able to produce around 720,000 tablets per hour.

But that's not all. Kilian also has plans to equip the machines in its lower price segment with the new HMI system, featuring the newly developed user interface and B&R technology. "The modular structure of our software, which separates design from functionality, together with the scalability of B&R's technology, will enable us to offer a state-of-the-art solution in this class as well – with relatively little effort," concludes Carstens.