8LS | b | c | d | . | ee | nnn | ff | gg | - | h | ||||||||||||||||

Cooling / Construction type | ||||||||||||||||||||||||||

Size | ||||||||||||||||||||||||||

Length | ||||||||||||||||||||||||||

Motor encoder system | ||||||||||||||||||||||||||

Nominal speed | ||||||||||||||||||||||||||

Motor options | ||||||||||||||||||||||||||

Special motor options | ||||||||||||||||||||||||||

Motor version | ||||||||||||||||||||||||||

Order keys only provide information about possible combinations in exceptional cases.

Information about possible combinations is available in the CAD configurator.

Additional information

8LS synchronous motors

8LS - General motor data

8LS - Order key

8LS standard motors

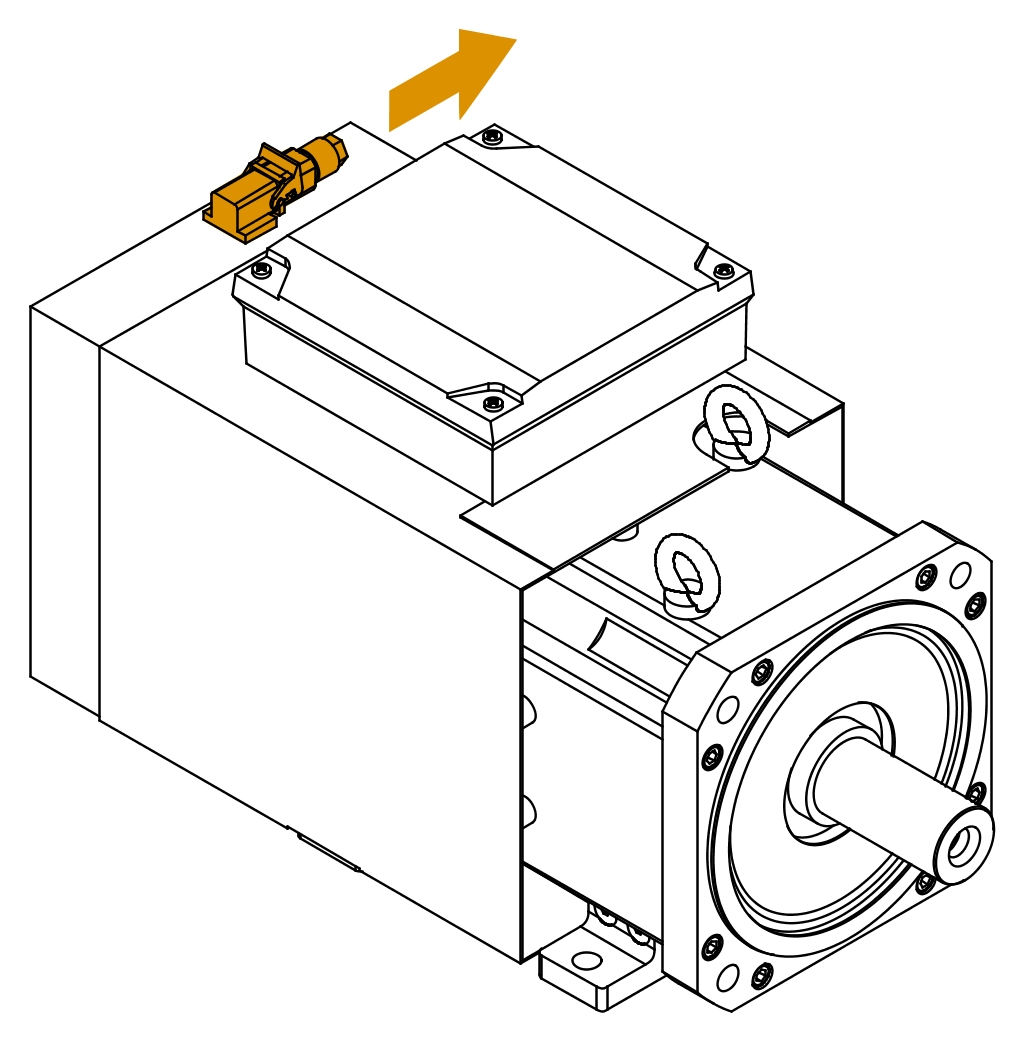

Embedded parameter chip

Cooling type / Construction type (b)

Cooling type / Construction type (b)

8LS | b | c | d | . | ee | nnn | ff | gg | - | h | |||||||||||

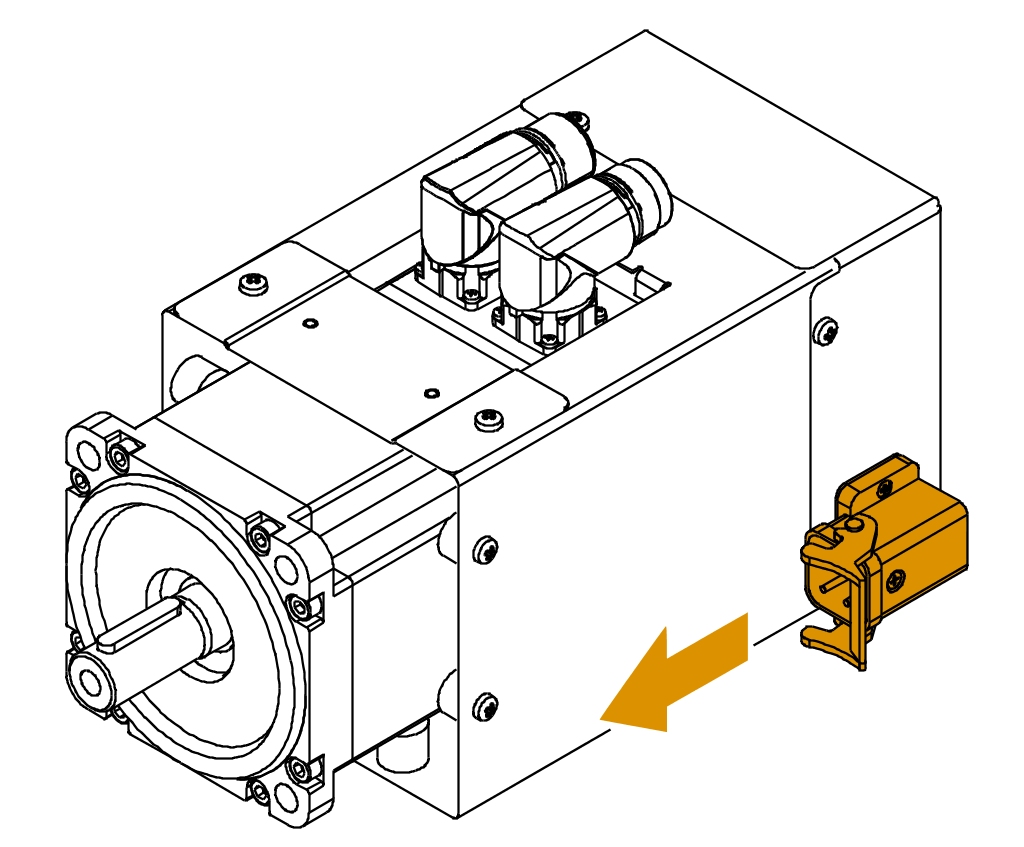

8LS three-phase synchronous motors are available in cooling types 8LSA, 8LSC, 8LSO and 8LSP. All motors are based on cooling type A (elongated, slim) and can deviate in this, the cable connection or mounting type.

The cooling types are differentiated by a letter (b) in the order number.

Cooling type (b) | Connection type | Available mounting types | ||

|---|---|---|---|---|

Mounting flange | Mounting flange and mounting base | |||

8LSA | Self-cooling | Connector | Yes | --- |

8LSC | Built-in fan assembly | Connector | Yes | --- |

8LSO | Self-cooling | Terminal box | Yes | Yes |

8LSP | Built-in fan assembly | Terminal box | --- | Yes |

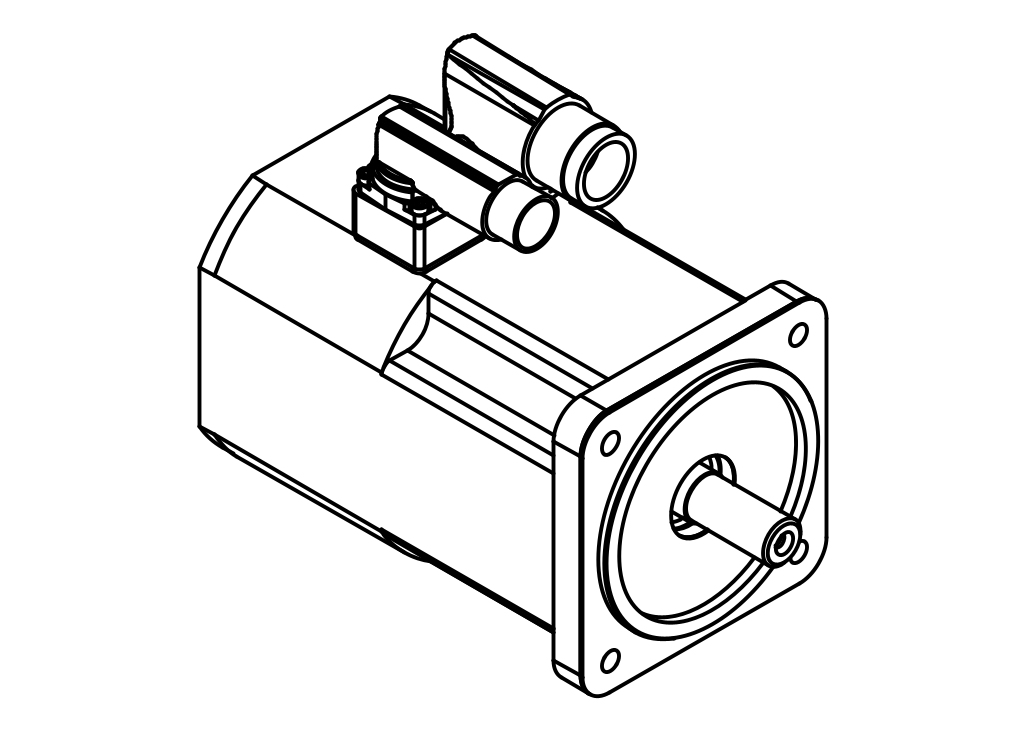

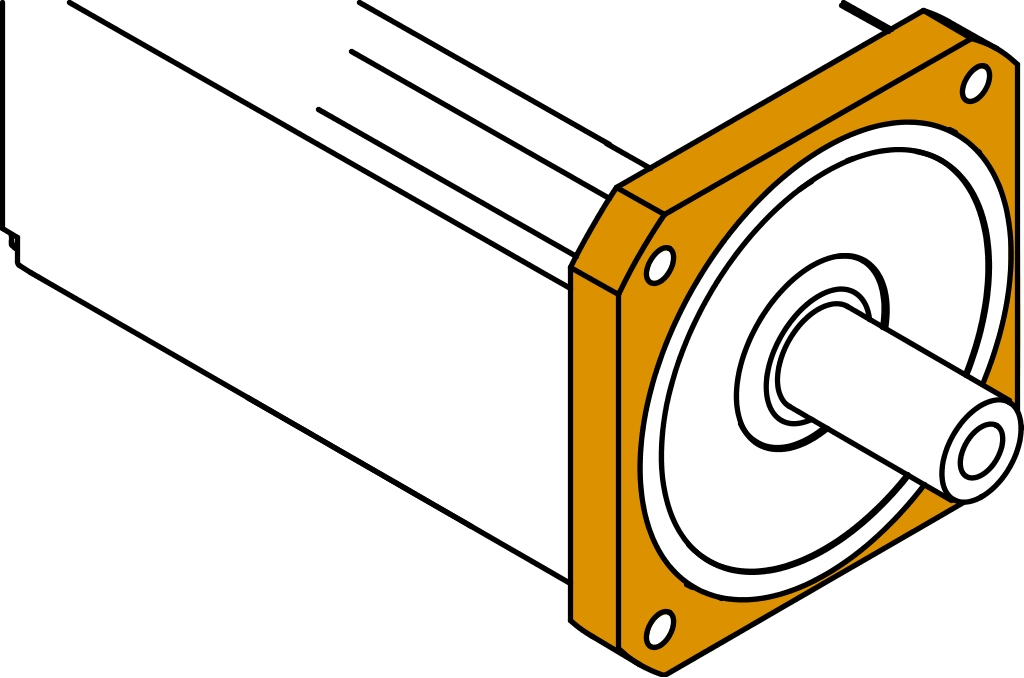

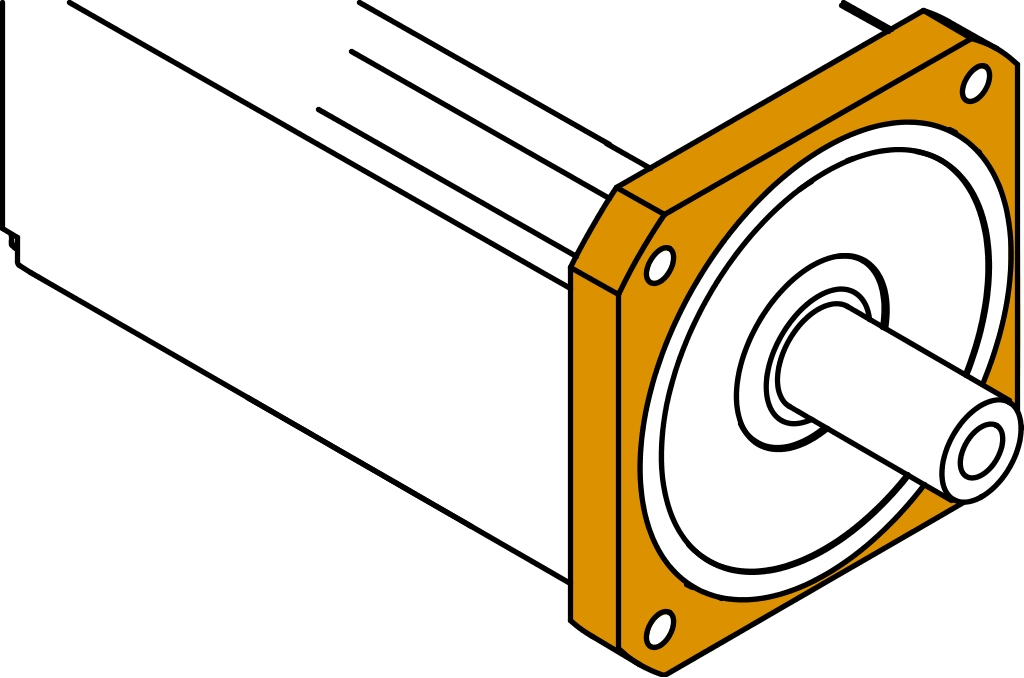

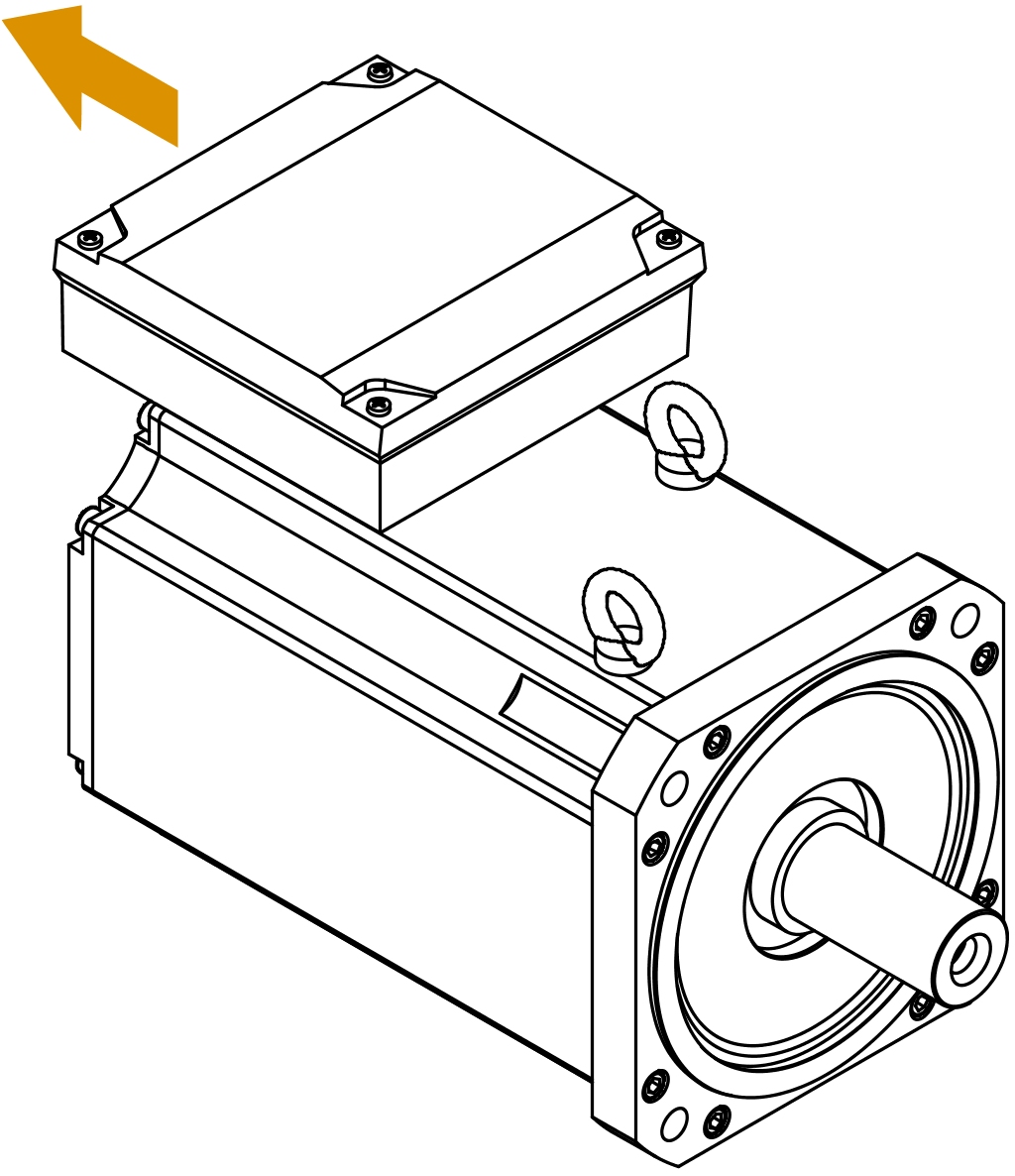

8LSA

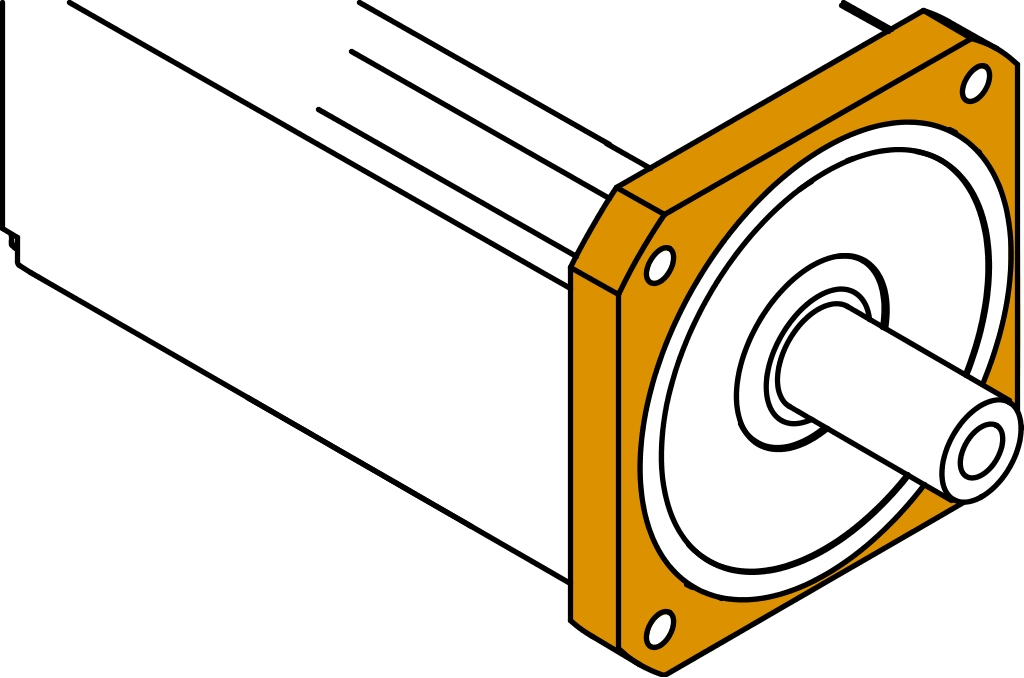

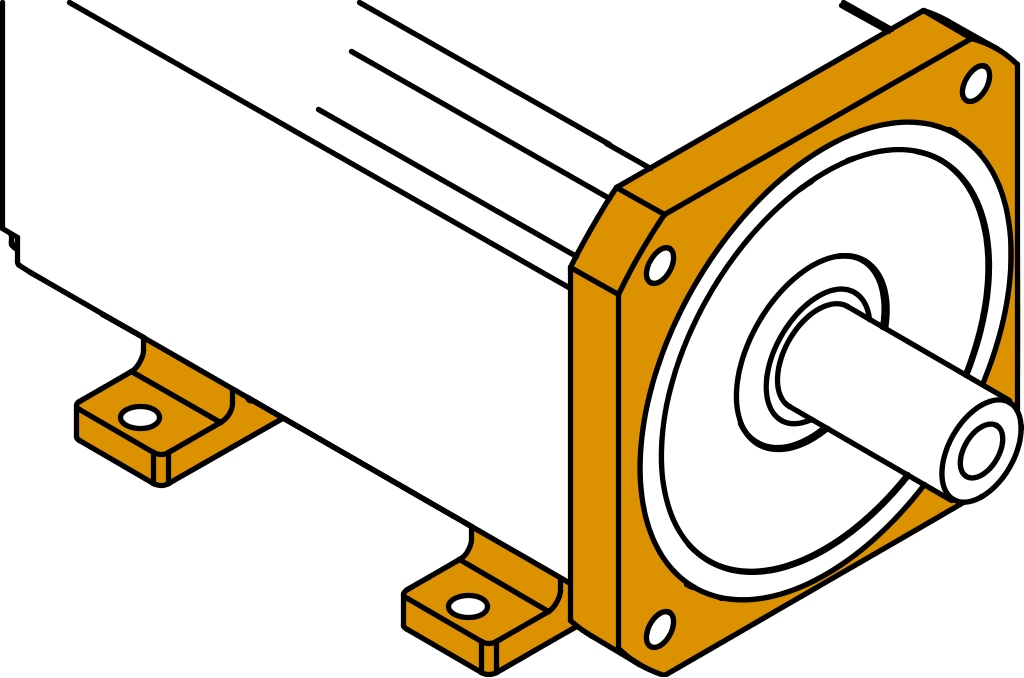

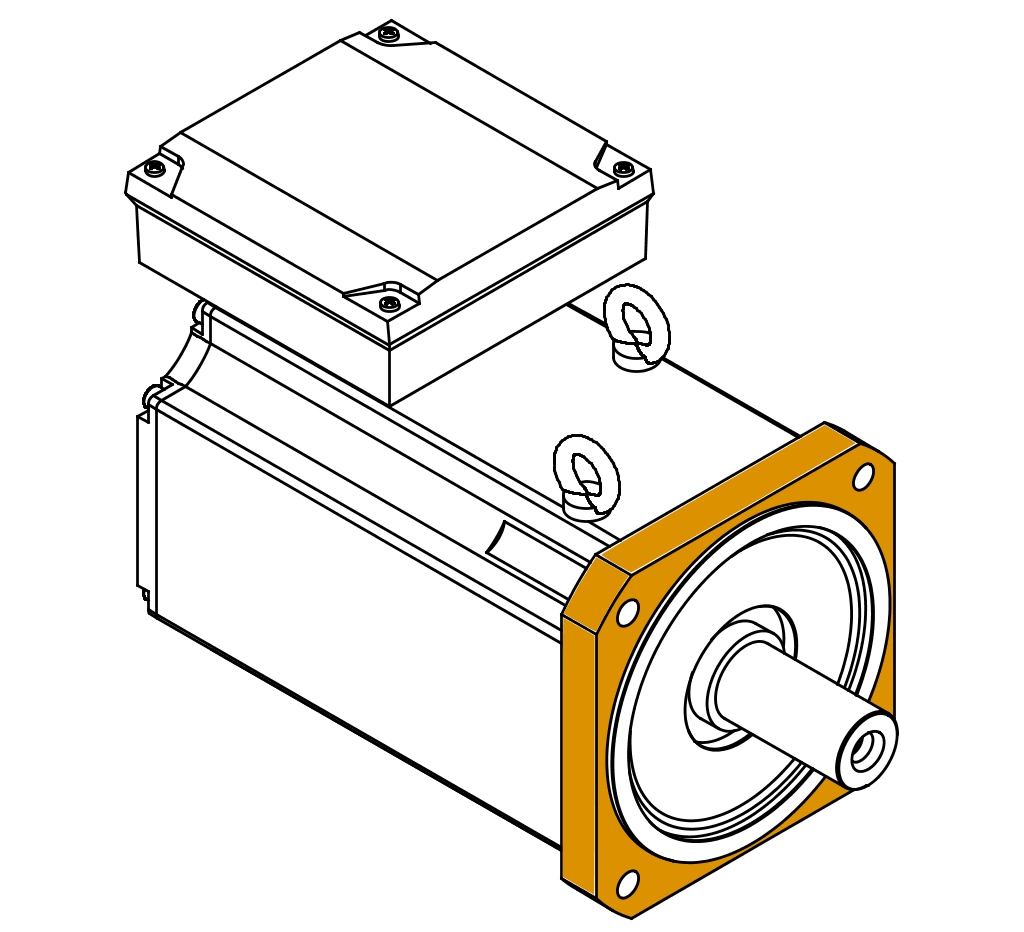

| Cooling type 8LSA is self-cooling and has a slim, elongated design. These motors must be attached to the machine with the mounting flange, which also serves as a cooling surface. |

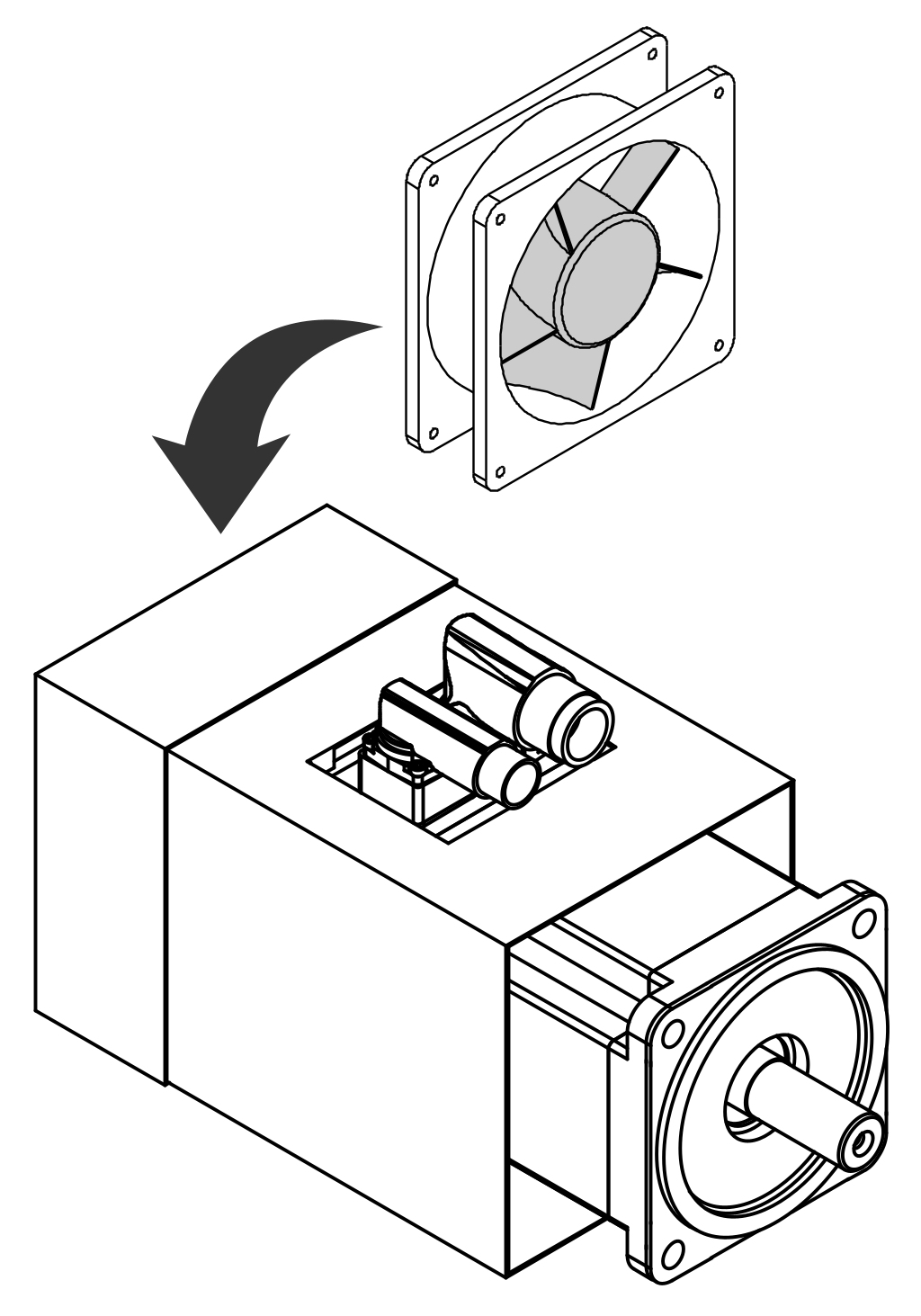

8LSC

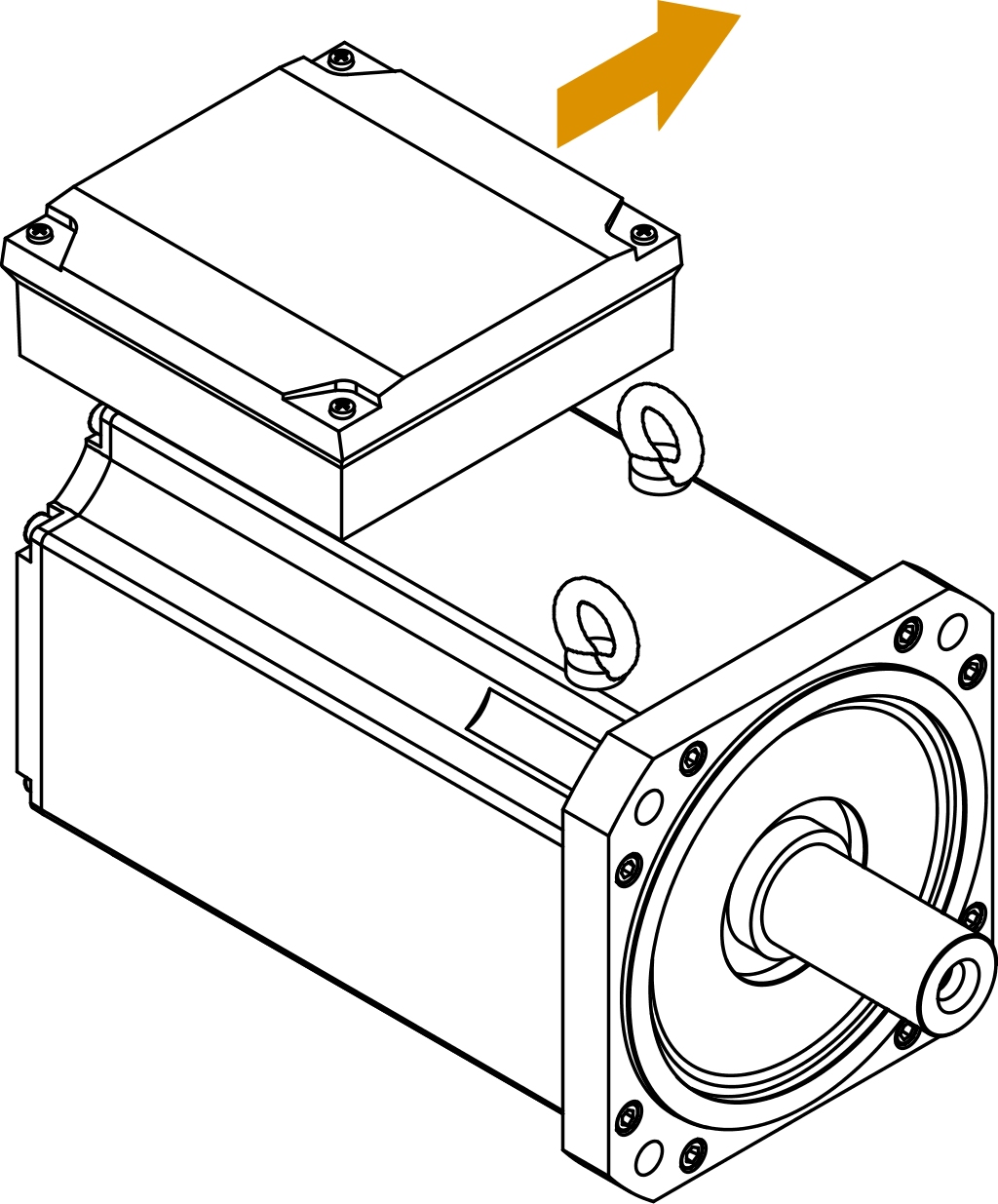

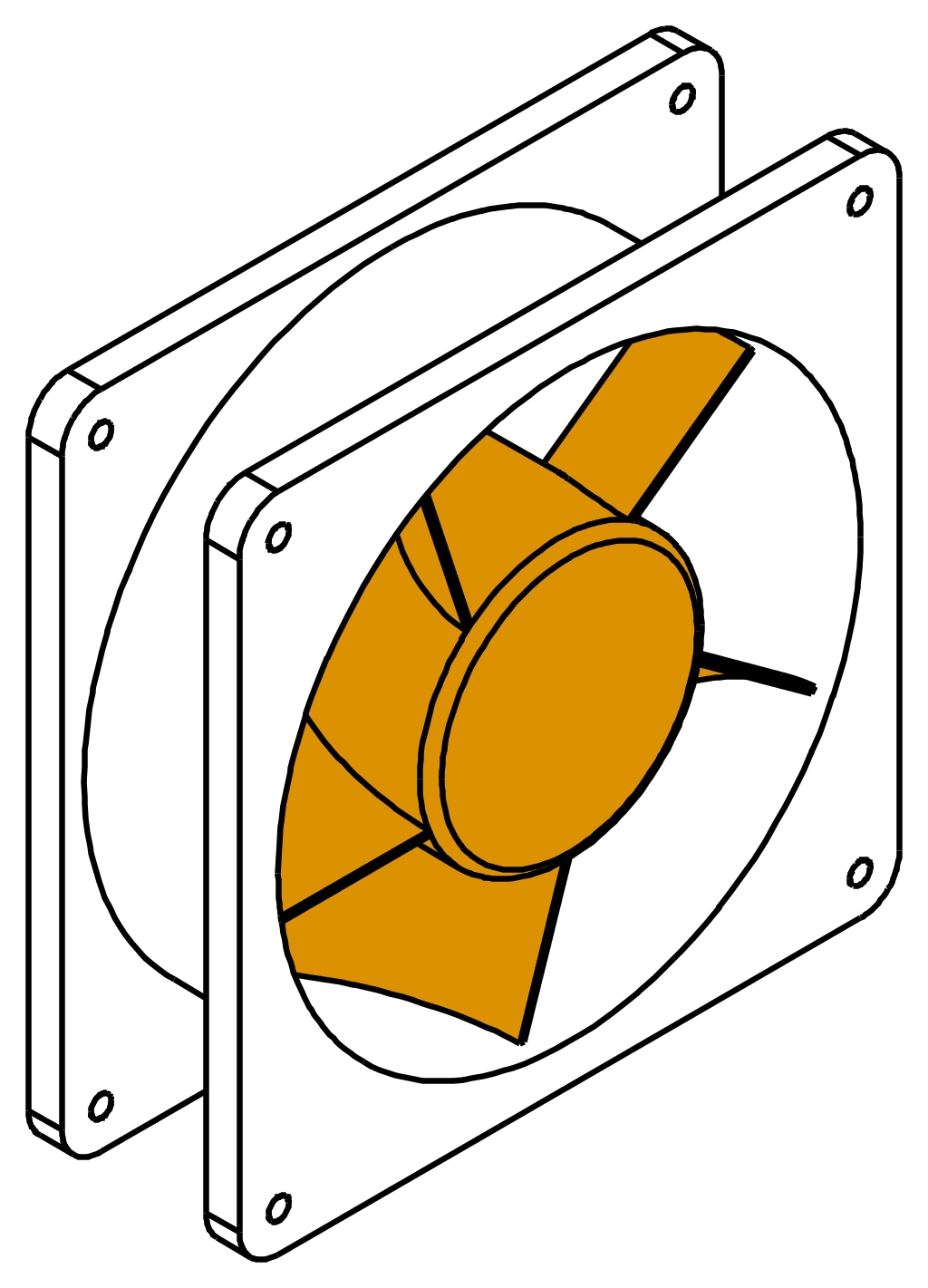

| Cooling type 8LSC is based on motors with cooling type 8LSA. These motors are externally cooled and differ only by a fan assembly mounted in the area of the B-side bearing. These motors must be attached to the machine with the mounting flange, which also serves as a cooling surface. Depending on the mounting situation, the attached fan assembly increases the nominal torque (MN), nominal current (IN), stall torque (M0) and stall current (I0) by 30% compared to the motors with cooling type 8LSA. |

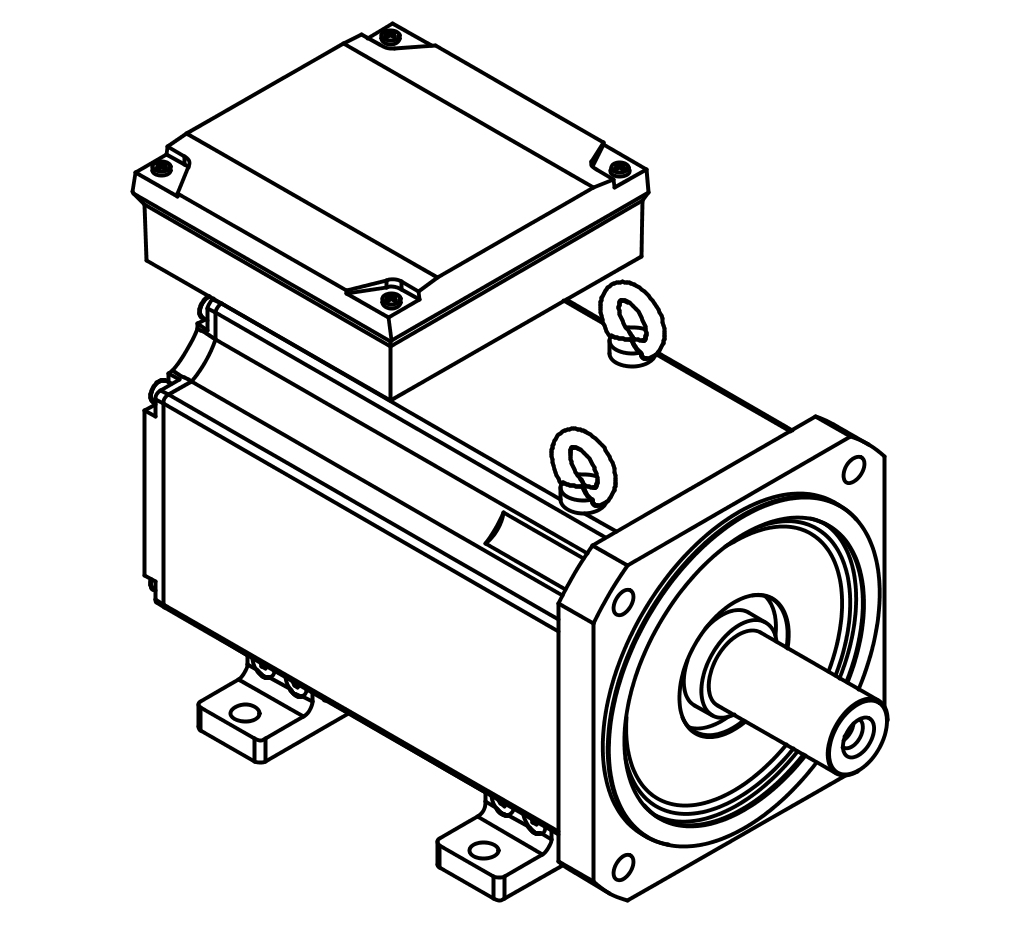

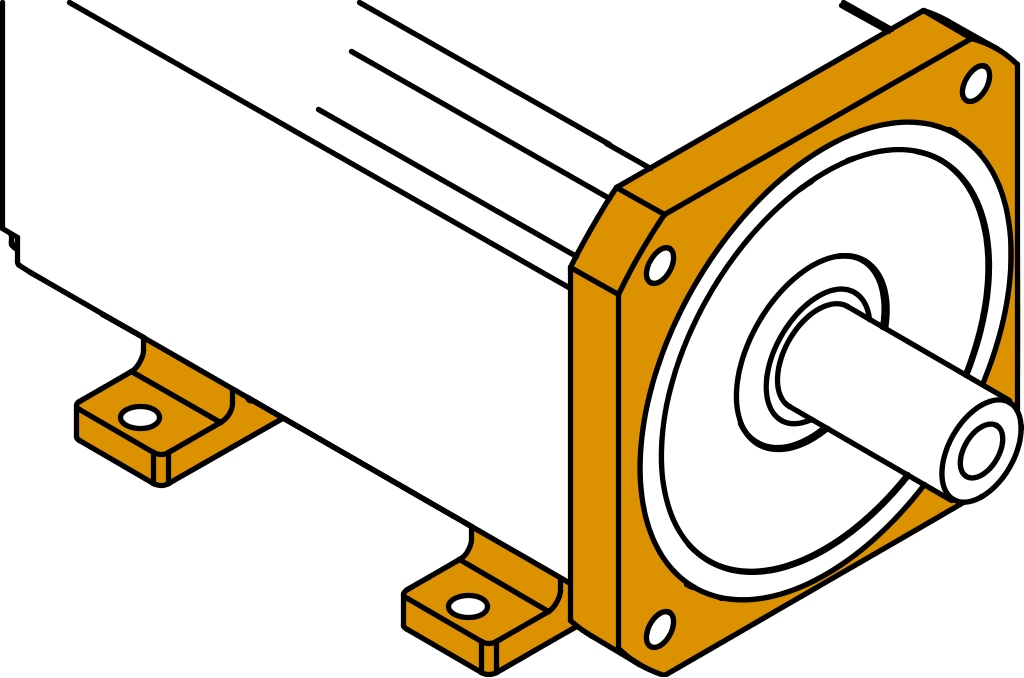

8LSO

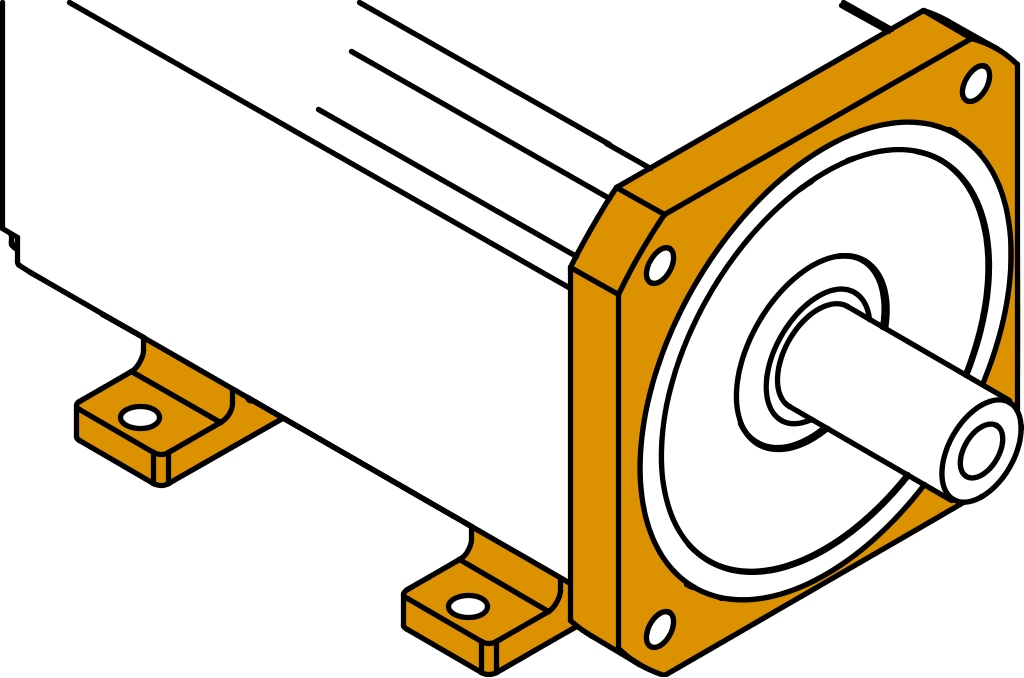

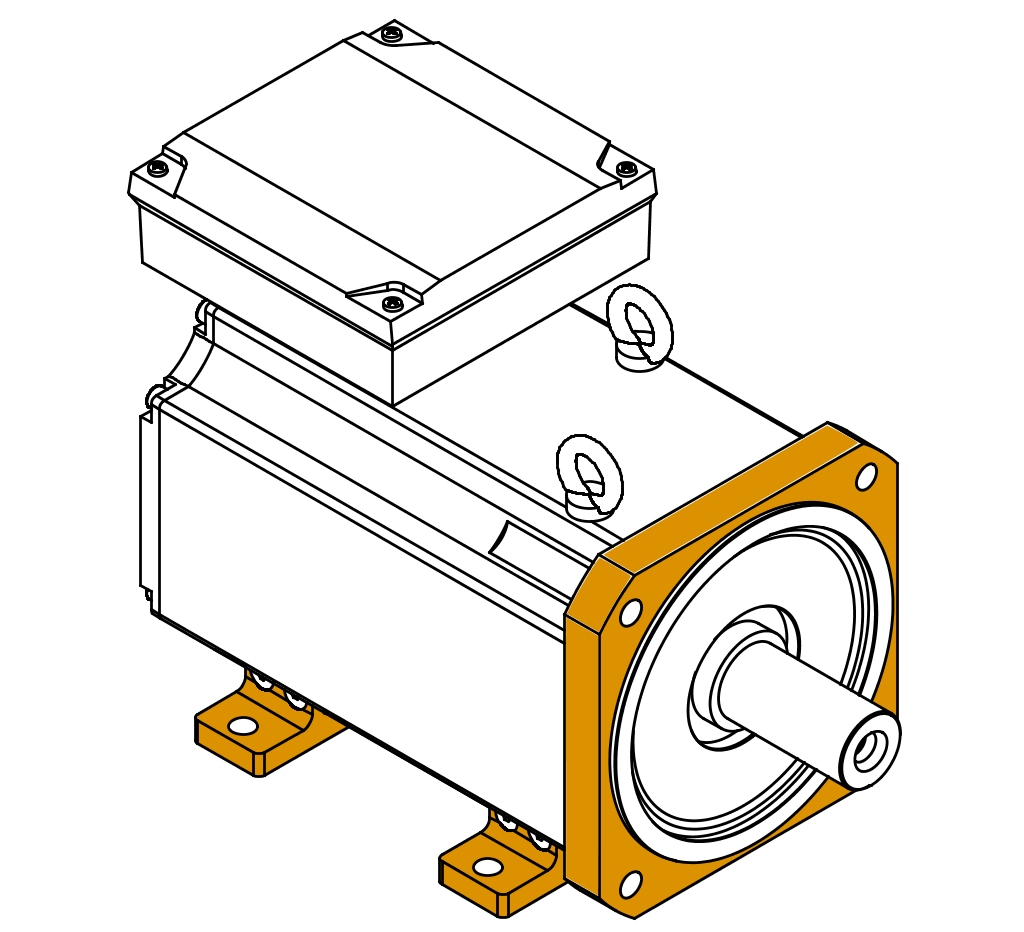

| Cooling type 8LSO is self-cooling and has a slim, elongated design. These motors can be mounted to the machine with the mounting flange, which also serves as a cooling surface, or with the mounting base. If the motor is only mounted with the mounting base and not with the mounting flange, the continuous power is reduced in S1 operation. |

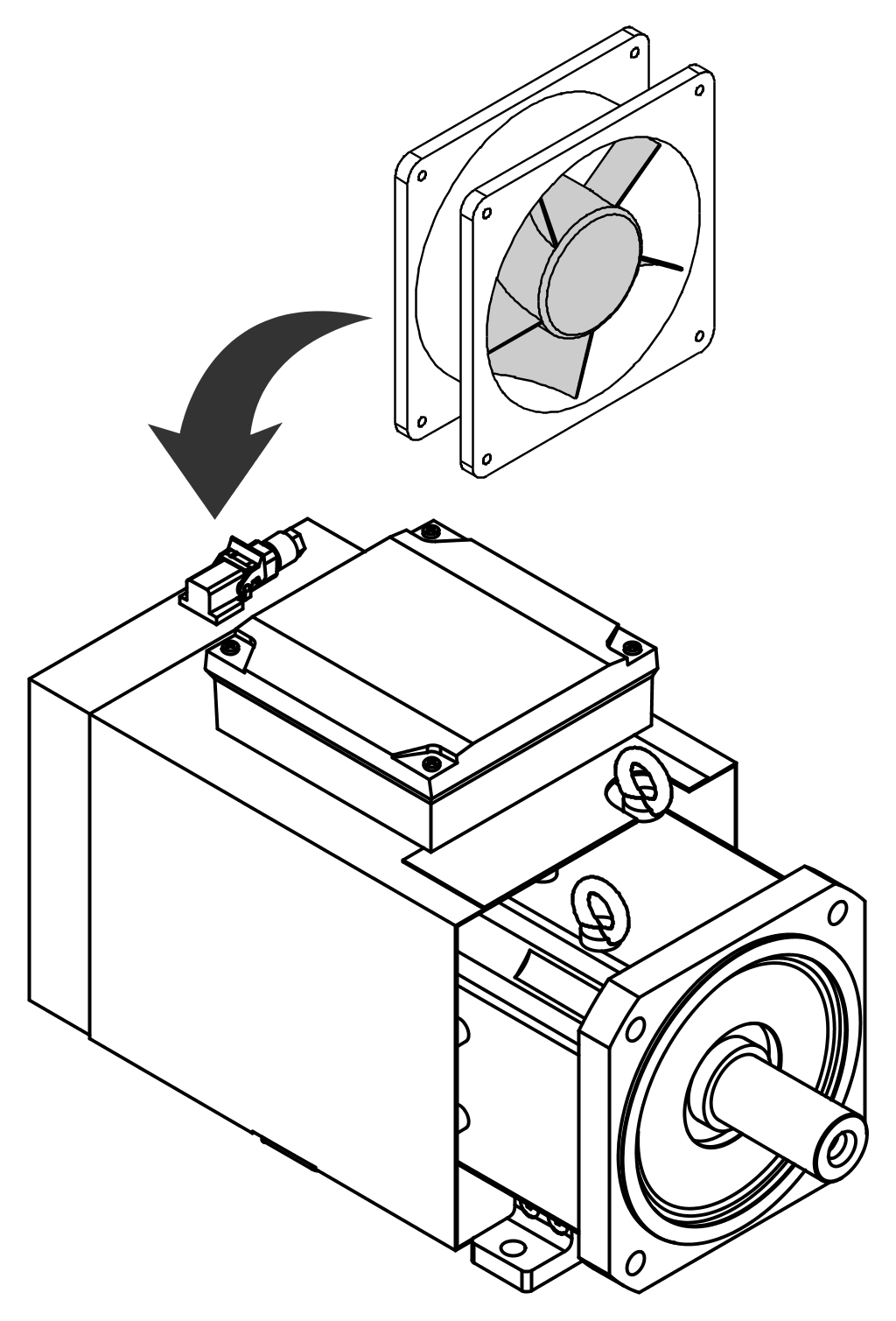

8LSP

| Cooling type 8LSP is based on motors with cooling type 8LSO. These motors are externally cooled and differ only by a fan assembly mounted in the area of the B-side bearing. These motors can be mounted to the machine with the mounting flange, which also serves as a cooling surface, or with the mounting base. If the motor is only mounted with the mounting base and not with the mounting flange, the continuous power is reduced in S1 operation. Depending on the mounting situation, the attached fan assembly increases the nominal torque (MN), nominal current (IN), stall torque (M0) and stall current (I0) by 30% compared to the motors with cooling type 8LSO. For transport reasons, this cooling type always has mounting base. |

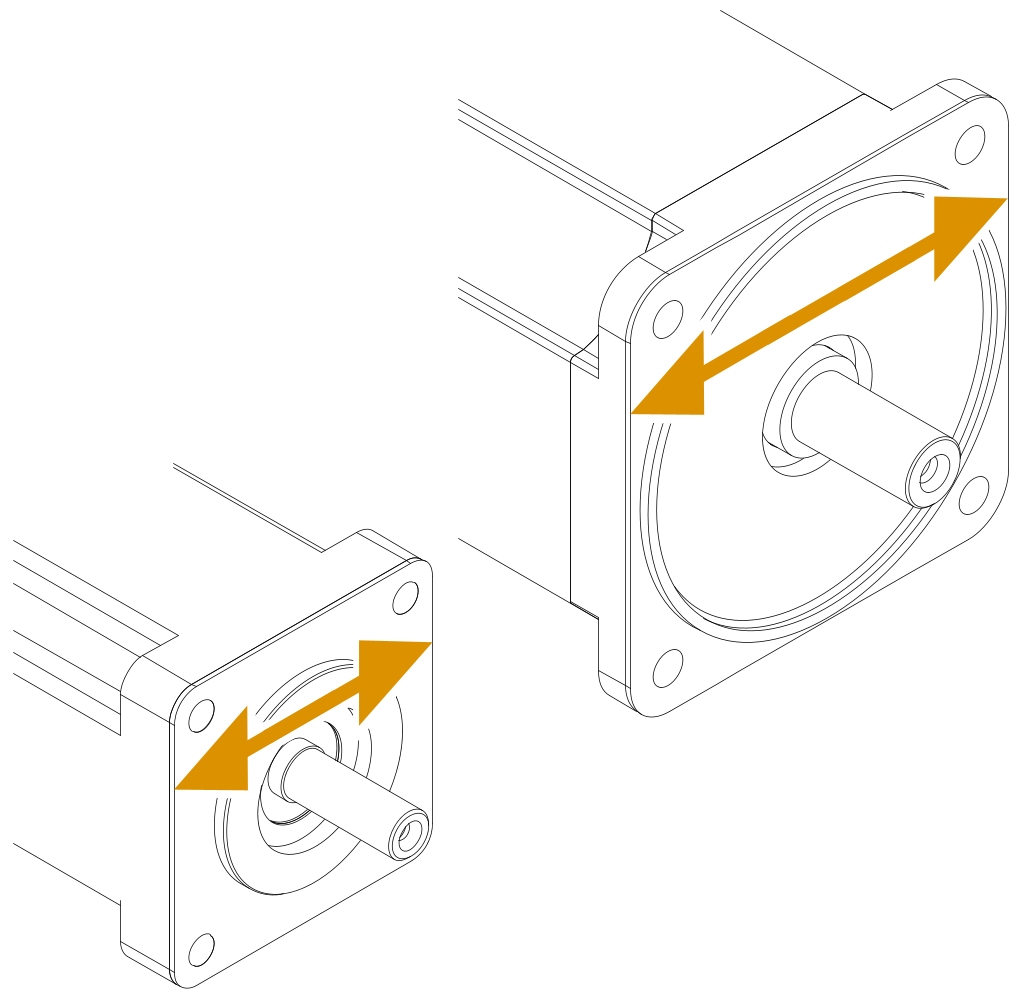

Size (c)

Size (c)

8LS | b | c | d | . | ee | nnn | ff | gg | - | h | |||||||||||

| 8LS three-phase synchronous motors are available in various sizes (2, A, 3 ... 9). These differ in dimensions (especially flange dimensions) and power data. The sizes are differentiated by a character (c) in the order number. The larger this number, the larger the flange dimensions and power data of the respective motor. |

Availability

Available sizes (c) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

8LSx2 | 8LSxA | 8LSx3 | 8LSx4 | 8LSx5 | 8LSx6 | 8LSx7 | 8LSx8 | 8LSx9 | |

Flange size [mm] | 58 | 70 | 91.3 | 100 | 142 | 190 | 190 | 240 | 269.9 |

8LSA | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | --- |

8LSC | --- | --- | --- | Yes | Yes | Yes | Yes | Yes | --- |

8LSO | --- | --- | --- | --- | --- | --- | --- | --- | Yes |

8LSP | --- | --- | --- | --- | --- | --- | --- | --- | Yes |

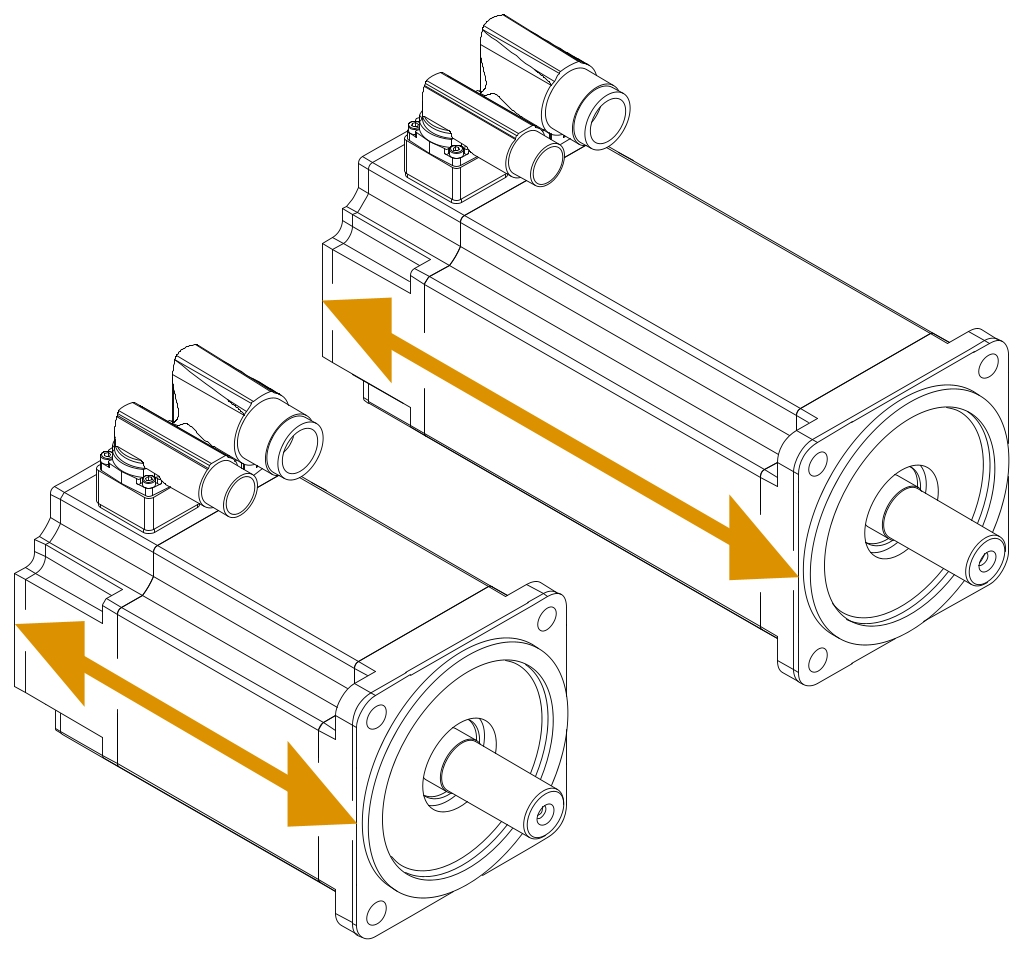

Length (d)

Length (d)

8LS | b | c | d | . | ee | nnn | ff | gg | - | h | |||||||||||

| 8LS three-phase synchronous motors are available in different lengths. These differ in the power data with identical flange dimensions. The lengths are differentiated by a number (d) in the order number. The larger this number, the longer the respective motor. |

Availability

Available lengths (d) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

8LSxx2 | 8LSxx3 | 8LSxx4 | 8LSxx5 | 8LSxx6 | 8LSxx7 | 8LSxx8 | 8LSxxA | 8LSxxB | 8LSxxC | |

8LSA2 | --- | Yes | Yes | Yes | Yes | --- | --- | --- | --- | --- |

8LSAA | Yes | Yes | Yes | --- | --- | --- | --- | --- | --- | --- |

8LSA3 | --- | Yes | Yes | Yes | Yes | Yes | --- | --- | --- | --- |

8LSA4 / 8LSC4 | --- | Yes | Yes | Yes | Yes | --- | --- | --- | --- | --- |

8LSA5 / 8LSC5 | --- | Yes | Yes | Yes | Yes | Yes | --- | Yes | Yes | Yes |

8LSA6 / 8LSC6 | --- | Yes | Yes | Yes | Yes | --- | --- | --- | --- | --- |

8LSA7 / 8LSC7 | --- | Yes | Yes | Yes | Yes | Yes | Yes | --- | --- | --- |

8LSA8 / 8LSC8 | --- | Yes | Yes | Yes | Yes | --- | --- | --- | --- | --- |

8LSO9 / 8LSP9 | --- | Yes | Yes | Yes | Yes | --- | --- | --- | --- | --- |

Motor encoder systems (ee)

8LS | b | c | d | . | ee | nnn | ff | gg | - | h | |||||||||||

8LS three-phase synchronous motors are available with EnDat encoders as well as resolvers. The motor encoder system is specified as part of the order number in the form of a 2-digit code (ee).

Resolver

A resolver is an analog encoder system. Resolvers are particularly robust against vibrations and high operating temperatures. Their disadvantage is the low precision of 6-10 arcminutes. There is still no multi-turn variant with resolvers.

Technical data | Order code (ee) | |

|---|---|---|

R0 | R2 | |

Precision ['] | 10 | 6 |

Vibration during operation [m/s2] | 10 < f ≤ 500 Hz: ≤196 | 55 < f ≤ 2000 Hz: <500 |

Shock during operation [m/s2] (11 ms duration) | ≤981 | ≤1000 |

Availability | Available resolvers / Order code (ee) | |

|---|---|---|

R0 | R2 | |

8LSA2...-3 | Yes | --- |

8LSAA...-3 | Yes | --- |

8LSA3/4/5/6/7/8...-3 | --- | Yes |

8LSx5A/B/C...-3 | --- | Yes |

8LSC...-3 | --- | Yes |

8LSO...-3 8LSP...-3 | --- | Yes |

Digital encoders - EnDat

Digital encoders use a serial transfer protocol. This protocol is called EnDat. The EnDat protocol is a developed standard that incorporates the advantages of absolute and incremental position measurement and also offers a read/write parameter memory in the encoder. The embedded parameter chip is stored by B&R in this encoder memory. This data and the B&R ACOPOS systems form a "plug-and-play" drive solution. Absolute positioning can be used within a revolution with the "single-turn" variants. A homing procedure is not required because of the absolute position measurement. For applications where the motor covers several revolutions for positioning, a "multi-turn" encoder that can save up to 65535 revolutions can be used. A solution with a single-turn encoder variant with a homing procedure is also possible. In EnDat 2.1 analog/digital sampling, a very fine resolution is achieved by the evaluation modules developed by B&R.

For the advanced, fully digital EnDat 2.2 protocol, the positions are generated directly in the encoder and communicated serially with the drive system. This transfer is very robust in relation to disturbances and is even certified for safety applications.

EnDat 2.2 is therefore to be preferred over the older EnDat 2.1 variant.

Inductive EnDat encoders for sizes 2 and A

Technical data | Encoder type / Order code (ee) | |||

|---|---|---|---|---|

D8 | D9 | S8 | S9 | |

Operating principle | Inductive | |||

EnDat protocol | 2.2 | 2.2 | 2.2 | 2.2 |

Functional safety1) | Yes | Yes | Yes | Yes |

Single-turn/Multi-turn | S | M | S | M |

Revolutions | 1 | 4096 | 1 | 4096 |

Resolution [bits single-turn / bits multi-turn] | 19/0 | 19/12 | 19/0 | 19/12 |

Precision ["] | 120 | |||

Cutoff frequency ≥ [kHz] | Digital pos. in the encoder | |||

Stator - Vibration during operation Max. [m/s2] | 400 | |||

Rotor - Vibration during operation Max. [m/s2] | 600 | |||

Max. shock during operation [m/s2] | 2000 | |||

Probability of dangerous failure per hour (PFH) SIL 2 | ≤15 * 10-9 | |||

Manufacturer's product ID | ECI 1119 FS EnDat22 | EQI 1131 FS EnDat22 | ECI 1119 FS EnDat22 | EQI 1131 FS EnDat22 |

| 1) | See appendix B "Safety level overview for ACOPOS product family safety functions" in the SafeMOTION user's manual (MAACPMSAFEMC-ENG) in the Downloads section of the B&R website (www.br-automation.com). There are additional limitations when combining B&R motors with a gearbox, see section "1.2.1 ACOPOSmulti SafeMOTION EnDat 2.2 and ACOPOS P3 SafeMOTION" in the SafeMOTION user's manual (MAACPMSAFEMC-ENG) in the Downloads section of the B&R website (www.br-automation.com). |

Availability | Available encoders / Order code (ee) | |||

|---|---|---|---|---|

D8 | D9 | S8 | S9 | |

8LSx2...-3 | Yes | Yes | Yes | Yes |

8LSAA...-3 | Yes | Yes | --- | --- |

Optical EnDat encoders for sizes 2 and A

Technical data | Encoder type / Order code (ee) | |||

|---|---|---|---|---|

E4 | E5 | D4 | D5 | |

Operating principle | Optical | |||

EnDat protocol | 2.1 | 2.1 | 2.2 | 2.2 |

Functional safety1) | --- | --- | Yes | Yes |

Single-turn/Multi-turn | S | M | S | M |

Revolutions | 1 | 4096 | 1 | 4096 |

Resolution [bits single-turn / bits multi-turn] | 13/0 | 13/12 | 23/0 | 23/12 |

Precision ["] | 60 | |||

Cutoff frequency ≥ [kHz] | 190 | Digital pos. in the encoder | ||

Stator - Vibration during operation Max. [m/s2] | 200 | |||

Rotor - Vibration during operation Max. [m/s2] | 200 | |||

Max. shock during operation [m/s2] | 1000 | |||

Probability of dangerous failure per hour (PFH) SIL 2 | --- | --- | ≤15 * 10-9 | |

Manufacturer's product ID | ECN 1113 EnDat01 | EQN 1125 EnDat01 | ECN 1123 FS EnDat22 | EQN 1135 FS EnDat22 |

| 1) | See appendix B "Safety level overview for ACOPOS product family safety functions" in the SafeMOTION user's manual (MAACPMSAFEMC-ENG) in the Downloads section of the B&R website (www.br-automation.com.). There are additional limitations when combining B&R motors with a gearbox, see section "1.2.1 ACOPOSmulti SafeMOTION EnDat 2.2 and ACOPOS P3 SafeMOTION" in the SafeMOTION user's manual (MAACPMSAFEMC-ENG) in the Downloads section of the B&R website (www.br-automation.com). |

Availability | Available encoders / Order code (ee) | |||

|---|---|---|---|---|

E4 | E5 | D4 | D5 | |

8LSx2...-3 | Yes | Yes | Yes | Yes |

8LSAA...-3 | Yes | Yes | Yes | Yes |

Inductive EnDat encoders for sizes 3 - 9

Technical data | Encoder type / Order code (ee) | |||||

|---|---|---|---|---|---|---|

EA | EB | DA | DB | SA | SB | |

Operating principle | Inductive | |||||

EnDat protocol | 2.1 | 2.1 | 2.2 | 2.2 | 2.2 | 2.2 |

Functional safety1) | --- | --- | Yes | Yes | Yes | Yes |

Single-turn/Multi-turn | S | M | S | M | S | M |

Revolutions | 1 | 4096 | 1 | 4096 | 1 | 4096 |

Resolution [bits single-turn / bits multi-turn] | 19/0 | 19/12 | 19/0 | 19/12 | 19/0 | 19/12 |

Precision ["] | 180 | 65 | ||||

Cutoff frequency ≥ [kHz] | 6 | Digital pos. in the encoder | ||||

Stator - Vibration during operation Max. [m/s2] | 200 | 400 | ||||

Rotor - Vibration during operation Max. [m/s2] | 200 | 600 | ||||

Max. shock during operation [m/s2] | 2000 | 2000 | ||||

Probability of dangerous failure per hour (PFH) SIL 2 | --- | --- | ≤15 * 10-9 | |||

Manufacturer's product ID | ECI 1319 | EQI 1331 | ECI 1319 FS | EQI 1331 FS | ECI 1319 FS | EQI 1331 FS |

| 1) | See appendix B "Safety level overview for ACOPOS product family safety functions" in the SafeMOTION user's manual (MAACPMSAFEMC-ENG) in the Downloads section of the B&R website (www.br-automation.com.). There are additional limitations when combining B&R motors with a gearbox, see section "1.2.1 ACOPOSmulti SafeMOTION EnDat 2.2 and ACOPOS P3 SafeMOTION" in the SafeMOTION user's manual (MAACPMSAFEMC-ENG) in the Downloads section of the B&R website (www.br-automation.com). |

Availability | Available encoders / Order code (ee) | |||||

|---|---|---|---|---|---|---|

EA | EB 3) | DA | DB | SA | SB | |

8LSx2...-3 | --- | --- | --- | --- | --- | --- |

8LSx3/4/5/6/7/8...-32) | Yes | Yes | Yes | Yes | Yes | Yes |

8LSx5A/B/C...-3 | --- | --- | Yes | Yes | Yes | Yes |

8LSO93/94...-3 8LSP93/94...-3 | --- | --- | Yes | Yes | Yes | Yes |

8LSO95/96...-3 8LSP95/96...-3 | --- | --- | --- | --- | --- | --- |

| 2) | Not valid for 8LSx5A/B/C...-3 |

| 3) | Encoder type EB requires at least the following versions (ACP10_SYS version or firmware version) of the ACOPOS operating systems: |

Optical EnDat encoders for sizes 3 - 9

Technical data | Encoder type / Order code (ee) | |||||

|---|---|---|---|---|---|---|

E0 | E1 | D0 | D1 | S0 | S1 | |

Operating principle | Optical | |||||

EnDat protocol | 2.1 | 2.1 | 2.2 | 2.2 | 2.2 | 2.2 |

Functional safety1) | --- | --- | Yes | Yes | Yes | Yes |

Single-turn/Multi-turn | S | M | S | M | S | M |

Revolutions | 1 | 4096 | 1 | 4096 | 1 | 4096 |

Resolution [bits single-turn / bits multi-turn] | 13/0 | 13/12 | 25/0 | 25/12 | 25/0 | 25/12 |

Precision ["] | 60 | 20 | ||||

Cutoff frequency ≥ [kHz] | 130 | Digital pos. in the encoder | ||||

Stator - Vibration during operation Max. [m/s2] | 300 | |||||

Rotor - Vibration during operation Max. [m/s2] | 300 | |||||

Max. shock during operation [m/s2] | 2000 | |||||

Probability of dangerous failure per hour (PFH) SIL 2 | --- | --- | ≤10 * 10-9 | |||

Manufacturer's product ID | ECN 1313 | EQN 1325 | ECN 1325 FS | EQN 1337 FS | ECN 1325 FS | EQN 1337 FS |

| 1) | See appendix B "Safety level overview for ACOPOS product family safety functions" in the SafeMOTION user's manual (MAACPMSAFEMC-ENG) in the Downloads section of the B&R website (www.br-automation.com.). There are additional limitations when combining B&R motors with a gearbox, see section "1.2.1 ACOPOSmulti SafeMOTION EnDat 2.2 and ACOPOS P3 SafeMOTION" in the SafeMOTION user's manual (MAACPMSAFEMC-ENG) in the Downloads section of the B&R website (www.br-automation.com). |

Availability | Available encoders / Order code (ee) | |||||

|---|---|---|---|---|---|---|

E0 | E1 | D0 | D1 | S0 | S1 | |

8LSx2...-3 | --- | --- | --- | --- | --- | --- |

8LSx3/4/5/6/7/8...-3 8LSx5A/B/C...-3 | Yes | Yes | Yes | Yes | Yes | Yes |

8LSO...-3 8LSP...-3 | --- | --- | Yes | Yes | Yes | Yes |

Nominal speed (nnn)

Nominal speed (nnn)

8LS | b | c | d | . | ee | nnn | ff | gg | - | h | |||||||||||

| 8LS three-phase synchronous motors are available with different nominal speeds. The nominal speed is specified as part of the order number in the form of a 3-digit code (nnn). |

Order code (nnn) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

011 | 013 | 015 | 020 | 022 | 030 | 040 | 045 | 060 | |

Nominal speed nN [rpm] | 1100 | 1300 | 1500 | 2000 | 2200 | 3000 | 4000 | 4500 | 6000 |

8LSA - Availability

8LSA2

Available nominal speeds nN [rpm] | |||||||||

|---|---|---|---|---|---|---|---|---|---|

1100 | 1300 | 1500 | 2000 | 2200 | 3000 | 4000 | 4500 | 6000 | |

8LSA23 | --- | --- | --- | --- | --- | --- | --- | --- | Yes |

8LSA24 | --- | --- | --- | --- | --- | --- | --- | --- | Yes |

8LSA25 | --- | --- | --- | --- | --- | --- | --- | Yes | Yes |

8LSA26 | --- | --- | --- | --- | --- | --- | --- | Yes | Yes |

8LSAA

Available nominal speeds nN [rpm] | |||||||||

|---|---|---|---|---|---|---|---|---|---|

1100 | 1300 | 1500 | 2000 | 2200 | 3000 | 4000 | 4500 | 6000 | |

8LSAA | --- | --- | --- | --- | --- | Yes | --- | Yes | Yes |

8LSA3

Available nominal speeds nN [rpm] | |||||||||

|---|---|---|---|---|---|---|---|---|---|

1100 | 1300 | 1500 | 2000 | 2200 | 3000 | 4000 | 4500 | 6000 | |

8LSA33 | --- | --- | --- | --- | --- | Yes | --- | Yes | Yes |

8LSA34 | --- | --- | --- | --- | Yes | Yes | --- | Yes | Yes |

8LSA35 | --- | --- | --- | --- | Yes | Yes | --- | Yes | Yes |

8LSA36 | --- | --- | --- | --- | Yes | Yes | --- | Yes | Yes |

8LSA37 | --- | --- | --- | --- | Yes | Yes | --- | Yes | Yes |

8LSA4

Available nominal speeds nN [rpm] | |||||||||

|---|---|---|---|---|---|---|---|---|---|

1100 | 1300 | 1500 | 2000 | 2200 | 3000 | 4000 | 4500 | 6000 | |

8LSA43 | --- | --- | --- | --- | Yes | Yes | --- | Yes | Yes |

8LSA44 | --- | --- | --- | --- | Yes | Yes | --- | Yes | Yes |

8LSA45 | --- | --- | --- | --- | Yes | Yes | --- | Yes | Yes |

8LSA46 | --- | --- | --- | --- | Yes | Yes | --- | Yes | Yes |

8LSA5

Available nominal speeds nN [rpm] | |||||||||

|---|---|---|---|---|---|---|---|---|---|

1100 | 1300 | 1500 | 2000 | 2200 | 3000 | 4000 | 4500 | 6000 | |

8LSA53 | --- | --- | --- | --- | Yes | Yes | --- | Yes | --- |

8LSA54 | --- | --- | --- | --- | Yes | Yes | --- | Yes | --- |

8LSA55 | --- | --- | --- | --- | Yes | Yes | --- | Yes | --- |

8LSA56 | --- | --- | --- | --- | Yes | Yes | --- | Yes | --- |

8LSA57 | --- | --- | --- | --- | Yes | Yes | --- | Yes | --- |

8LSA5A | --- | --- | --- | --- | Yes | Yes | --- | Yes | --- |

8LSA5B | --- | --- | --- | --- | Yes | Yes | Yes | --- | --- |

8LSA5C | --- | --- | Yes | --- | Yes | Yes | --- | --- | --- |

8LSA6

Available nominal speeds nN [rpm] | |||||||||

|---|---|---|---|---|---|---|---|---|---|

1100 | 1300 | 1500 | 2000 | 2200 | 3000 | 4000 | 4500 | 6000 | |

8LSA63 | --- | --- | --- | --- | Yes | Yes | --- | Yes | --- |

8LSA64 | --- | --- | --- | --- | Yes | Yes | --- | Yes | --- |

8LSA65 | --- | --- | --- | --- | Yes | Yes | --- | Yes | --- |

8LSA66 | --- | --- | --- | --- | Yes | Yes | --- | Yes | --- |

8LSA7

Available nominal speeds nN [rpm] | |||||||||

|---|---|---|---|---|---|---|---|---|---|

1100 | 1300 | 1500 | 2000 | 2200 | 3000 | 4000 | 4500 | 6000 | |

8LSA73 | --- | --- | --- | --- | Yes | Yes | --- | Yes | --- |

8LSA74 | --- | --- | --- | --- | Yes | Yes | --- | Yes | --- |

8LSA75 | Yes | --- | --- | --- | Yes | Yes | --- | --- | --- |

8LSA76 | --- | --- | Yes | --- | Yes | Yes | --- | --- | --- |

8LSA77 | --- | --- | --- | --- | --- | Yes | --- | --- | --- |

8LSA78 | --- | --- | --- | --- | --- | Yes | --- | --- | --- |

8LSA8

Available nominal speeds nN [rpm] | |||||||||

|---|---|---|---|---|---|---|---|---|---|

1100 | 1300 | 1500 | 2000 | 2200 | 3000 | 4000 | 4500 | 6000 | |

8LSA83 | --- | --- | Yes | --- | Yes | Yes | --- | --- | --- |

8LSA84 | --- | --- | Yes | --- | Yes | Yes | --- | --- | --- |

8LSA85 | --- | --- | Yes | Yes | --- | --- | --- | --- | --- |

8LSA86 | --- | --- | Yes | Yes | --- | --- | --- | --- | --- |

8LSC - Availability

8LSC4

Available nominal speeds nN [rpm] | |||||||||

|---|---|---|---|---|---|---|---|---|---|

1100 | 1300 | 1500 | 2000 | 2200 | 3000 | 4000 | 4500 | 6000 | |

8LSC43 | --- | --- | --- | --- | Yes | Yes | --- | Yes | Yes |

8LSC44 | --- | --- | --- | --- | Yes | Yes | --- | Yes | Yes |

8LSC45 | --- | --- | --- | --- | Yes | Yes | --- | Yes | Yes |

8LSC46 | --- | --- | --- | --- | Yes | Yes | --- | Yes | Yes |

8LSC5

Available nominal speeds nN [rpm] | |||||||||

|---|---|---|---|---|---|---|---|---|---|

1100 | 1300 | 1500 | 2000 | 2200 | 3000 | 4000 | 4500 | 6000 | |

8LSC53 | --- | --- | --- | --- | Yes | Yes | --- | Yes | --- |

8LSC54 | Yes | --- | --- | --- | Yes | Yes | --- | Yes | --- |

8LSC55 | --- | --- | --- | --- | Yes | Yes | --- | Yes | --- |

8LSC56 | --- | --- | --- | --- | Yes | Yes | --- | Yes | --- |

8LSC57 | --- | --- | --- | --- | Yes | Yes | --- | Yes | --- |

8LSC5A | --- | --- | --- | --- | Yes | Yes | --- | Yes | --- |

8LSC5B | --- | --- | --- | Yes | Yes | Yes | Yes | --- | --- |

8LSC5C | --- | --- | Yes | --- | Yes | Yes | --- | --- | --- |

8LSC6

Available nominal speeds nN [rpm] | |||||||||

|---|---|---|---|---|---|---|---|---|---|

1100 | 1300 | 1500 | 2000 | 2200 | 3000 | 4000 | 4500 | 6000 | |

8LSC63 | --- | --- | --- | --- | Yes | Yes | --- | Yes | --- |

8LSC64 | --- | --- | --- | --- | Yes | Yes | --- | Yes | --- |

8LSC65 | --- | --- | --- | --- | Yes | Yes | --- | Yes | --- |

8LSC66 | --- | --- | --- | --- | Yes | Yes | --- | Yes | --- |

8LSC7

Available nominal speeds nN [rpm] | |||||||||

|---|---|---|---|---|---|---|---|---|---|

1100 | 1300 | 1500 | 2000 | 2200 | 3000 | 4000 | 4500 | 6000 | |

8LSC73 | --- | --- | --- | --- | Yes | Yes | --- | Yes | --- |

8LSC74 | --- | --- | --- | --- | Yes | Yes | --- | Yes | --- |

8LSC75 | --- | --- | --- | --- | Yes | Yes | --- | --- | --- |

8LSC76 | --- | --- | Yes | --- | --- | Yes | --- | --- | --- |

8LSC77 | --- | --- | --- | --- | --- | Yes | --- | --- | --- |

8LSC78 | --- | --- | --- | --- | --- | Yes | --- | --- | --- |

8LSC8

Available nominal speeds nN [rpm] | |||||||||

|---|---|---|---|---|---|---|---|---|---|

1100 | 1300 | 1500 | 2000 | 2200 | 3000 | 4000 | 4500 | 6000 | |

8LSC83 | --- | --- | Yes | --- | Yes | Yes | --- | --- | --- |

8LSC84 | --- | --- | Yes | --- | Yes | Yes | --- | --- | --- |

8LSC85 | --- | --- | Yes | Yes | --- | --- | --- | --- | --- |

8LSC86 | --- | --- | Yes | Yes | --- | --- | --- | --- | --- |

8LSO / 8LSP - Availability

8LSO9

Available nominal speeds nN [rpm] | |||

|---|---|---|---|

1300 | 1500 | 2200 | |

8LSO93 | Yes | Yes | Yes |

8LSO94 | Yes | Yes | Yes |

8LSO95 | Yes | Yes | Yes |

8LSO96 | Yes | Yes | Yes |

8LSP9

Available nominal speeds nN [rpm] | |||

|---|---|---|---|

1300 | 1500 | 2200 | |

8LSP93 | Yes | Yes | Yes |

8LSP94 | Yes | Yes | Yes |

8LSP95 | Yes | Yes | Yes |

8LSP96 | Yes | Yes | Yes |

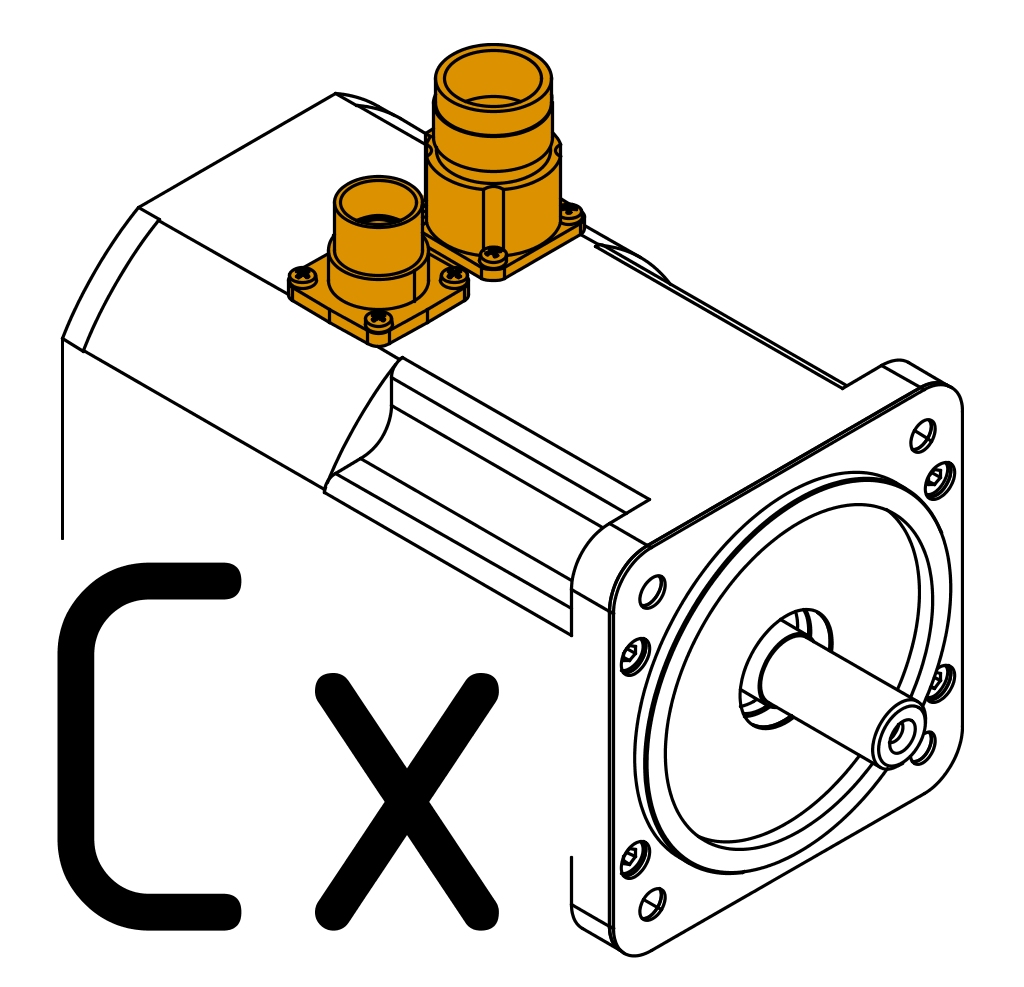

Motor options (ff)

8LS | b | c | d | . | ee | nnn | ff | gg | - | h | |||||||||||

See the following table for the corresponding code (ff) in the order key.

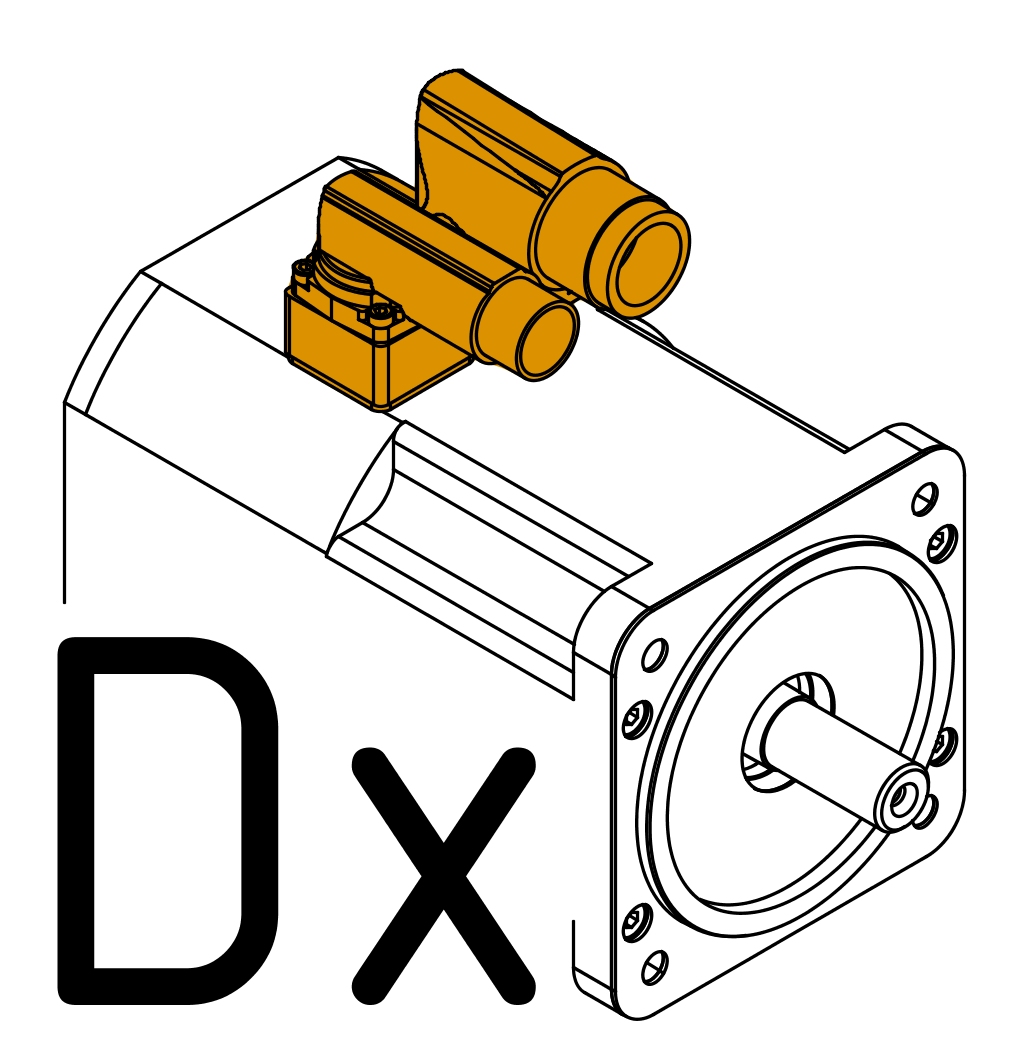

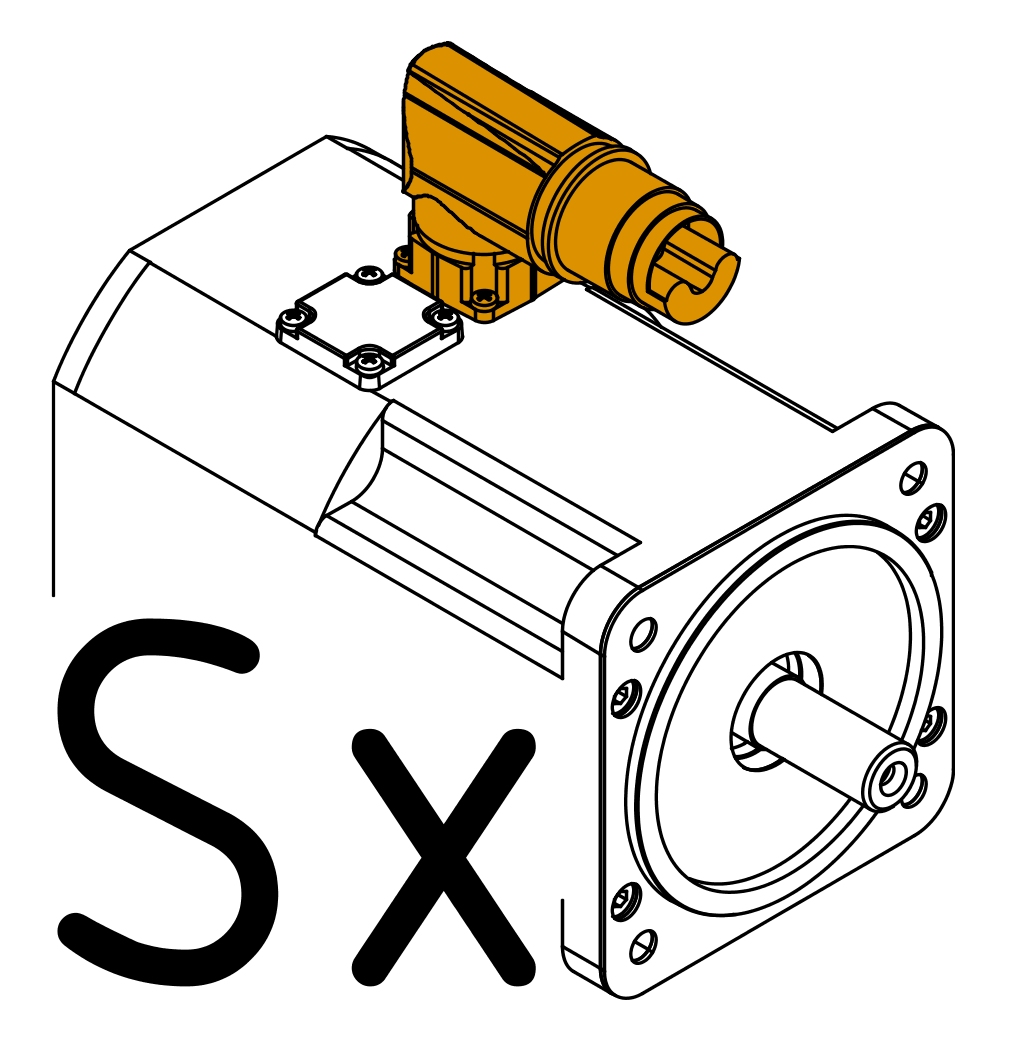

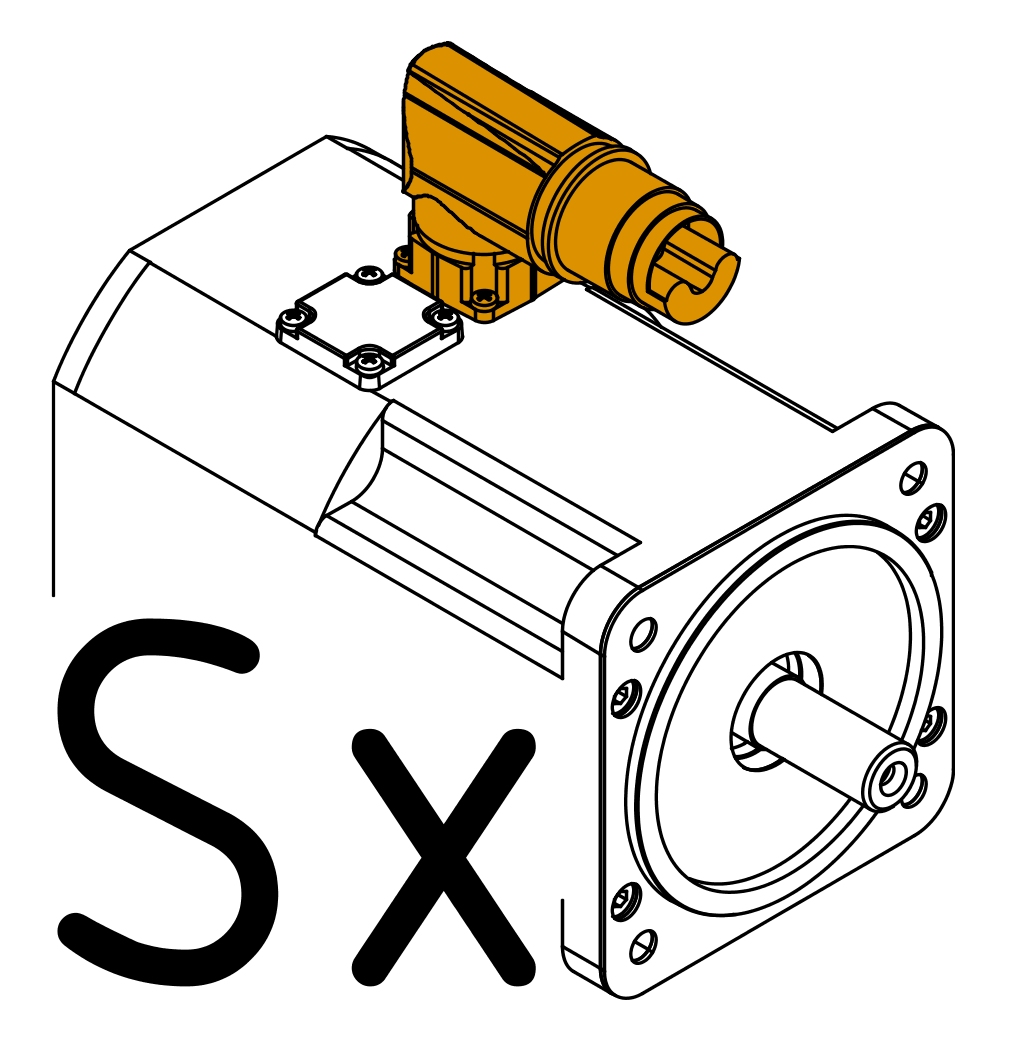

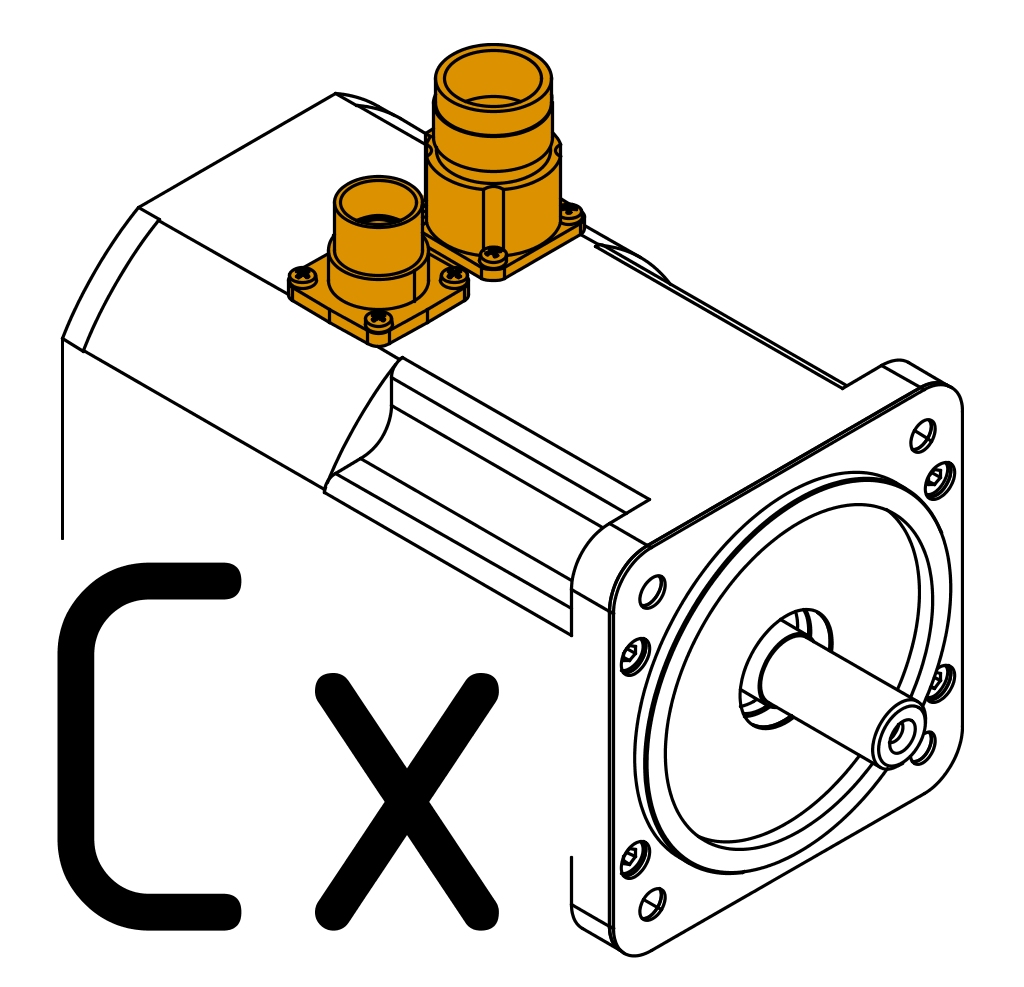

The first position in the code (ff) defines the connection direction with options Cx, Dx and Sx. The second position (e.g. x0, x1, x2, x3 ... xA, xB, xC) defines all other motor options according to the table.

- The combination "reinforced holding brake" with special motor option "reinforced A-side bearing" is not possible.

- Motors with reinforced bearings cannot be combined with gearboxes.

- A reinforced holding break is not available for 8LSA2, 8LSC2, 8LSAA, 8LSA8 or 8LSC8.

- A standard brake and reinforced holding brake are not available for 8LSA5C for technical reasons.

Motor option | Order code (ff) | ||||

|---|---|---|---|---|---|

Connection direction | Oil seal | Holding brake | Shaft end | ||

Straight (top connector)  Encoder and power cable: Separated with their own connections | --- | --- | Smooth shaft | C0 | |

--- | --- | With key | C1 | ||

--- | Standard holding brake |  | Smooth shaft | C2 | |

--- | With key | C3 | |||

--- | Heavy-duty holding brake |  | Smooth shaft | C4 | |

--- | With key | C5 | |||

Yes | --- | Smooth shaft | C6 | ||

Yes | --- | With key | C7 | ||

Yes | Standard holding brake |  | Smooth shaft | C8 | |

Yes | With key | C9 | |||

Yes | Heavy-duty holding brake |  | Smooth shaft | CA | |

Yes | With key | CB | |||

--- | Special-purpose holding brake2) |  | Smooth shaft | CC | |

--- | With key | CD | |||

Yes | Smooth shaft | CE | |||

Yes | With key | CF | |||

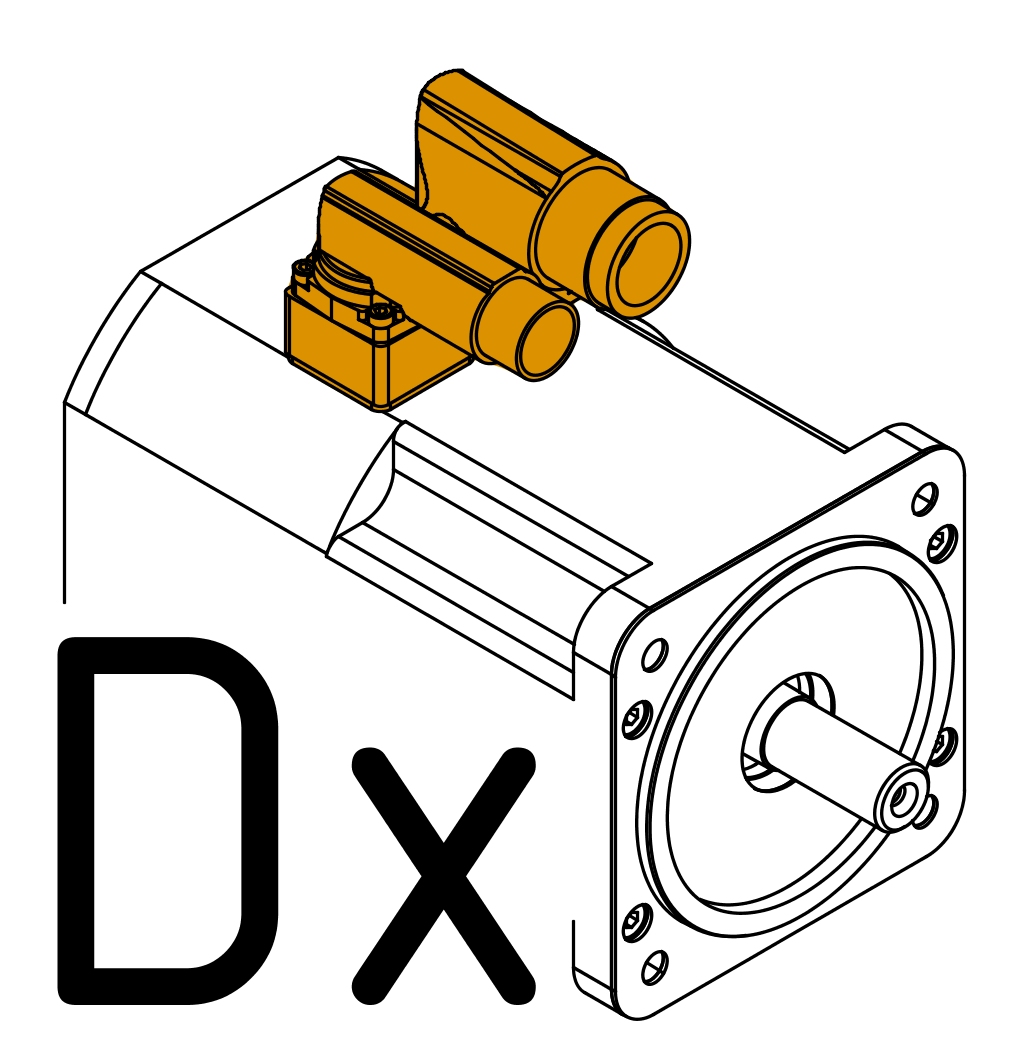

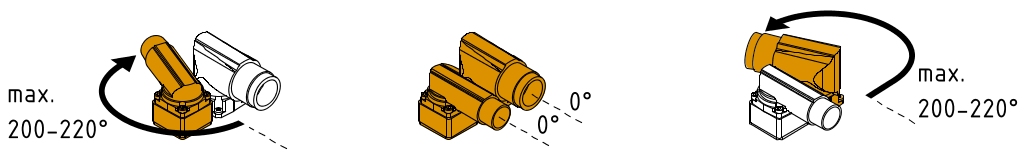

Angled (swivel)  Encoder and power cable: Separated with their own connections | --- | --- | Smooth shaft | D0 | |

--- | --- | With key | D1 | ||

--- | Standard holding brake |  | Smooth shaft | D2 | |

--- | With key | D3 | |||

--- | Heavy-duty holding brake |  | Smooth shaft | D4 | |

--- | With key | D5 | |||

Yes | --- | Smooth shaft | D6 | ||

Yes | --- | With key | D7 | ||

Yes | Standard holding brake |  | Smooth shaft | D8 | |

Yes | With key | D9 | |||

Yes | Heavy-duty holding brake |  | Smooth shaft | DA | |

Yes | With key | DB | |||

--- | Special-purpose holding brake2) |  | Smooth shaft | DC | |

--- | With key | DD | |||

Yes | Smooth shaft | DE | |||

Yes | With key | DF | |||

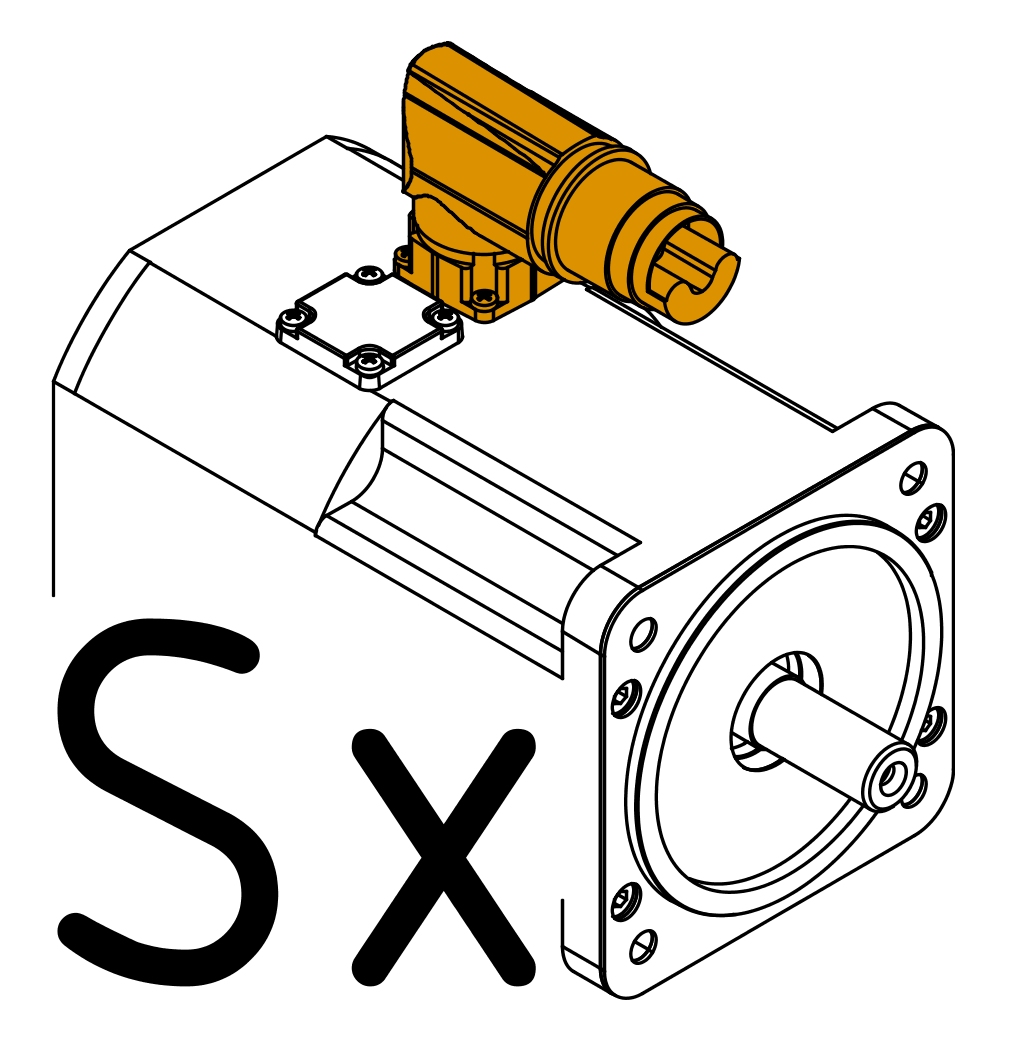

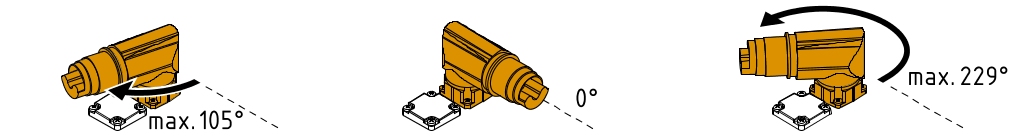

Single-cable solution (hybrid), angled, swivel connector  Encoder and power cable: Combined in one cable | --- | --- | Smooth shaft | S0 | |

--- | --- | With key | S1 | ||

--- | Standard holding brake |  | Smooth shaft | S2 | |

--- | With key | S3 | |||

--- | Heavy-duty holding brake |  | Smooth shaft | S4 | |

--- | With key | S5 | |||

Yes | --- | Smooth shaft | S6 | ||

Yes | --- | With key | S7 | ||

Yes | Standard holding brake |  | Smooth shaft | S8 | |

Yes | With key | S9 | |||

Yes | Heavy-duty holding brake |  | Smooth shaft | SA | |

Yes | With key | SB | |||

--- | Special-purpose holding brake2) |  | Smooth shaft | SC | |

--- | With key | SD | |||

Yes | Smooth shaft | SE | |||

Yes | With key | SF | |||

| 2) | The "special-purpose holding brake" is only available in combination with a "reinforced A-side bearing". See "Special motor options (gg) 8LSA / 8LSC". |

Availability of single-cable solution (hybrid)

Availability of single-cable solution (hybrid)

| There is no single-cable solution (hybrid) available for resolvers and EnDat 2.1 encoders. | |

The single-cable solution (hybrid) is only possible for motors with connector size 1.0 (built-in connector on the motor side) and therefore generally up to size/length 65. | ||

The following exceptions apply to individual motors with size/length 5A, 5B and 5C. The listed motors are therefore not available as a single-cable solution (hybrid). |

Cooling type A | Speed | Connector size | Single-cable solution (hybrid) available |

|---|---|---|---|

8LSA5A.ee045ffgg-3 | 4500 | 1.5 | --- |

8LSA5B.ee030ffgg-3 | 3000 | 1.5 | --- |

8LSA5B.ee040ffgg-3 | 4000 | 1.5 | --- |

8LSA5C.ee022ffgg-3 | 2200 | 1.5 | --- |

8LSA5C.ee030ffgg-3 | 3000 | 1.5 | --- |

Cooling type C | Speed | Connector size | Single-cable solution (hybrid) available |

|---|---|---|---|

8LSC5A.ee045ffgg-3 | 4500 | 1.5 | --- |

8LSC5B.ee030ffgg-3 | 3000 | 1.5 | --- |

8LSC5B.ee040ffgg-3 | 4000 | 1.5 | --- |

8LSC5C.ee022ffgg-3 | 2200 | 1.5 | --- |

8LSC5C.ee030ffgg-3 | 3000 | 1.5 | --- |

8LSA66 / 8LSC66 - Availability

Cooling type A | Speed | Connector size | Single-cable solution (hybrid) available |

|---|---|---|---|

8LSA66.ee015ffgg-3 | 1500 | 1 | Yes |

8LSA66.ee022ffgg-3 | 2200 | 1 | Yes |

8LSA66.ee030ffgg-3 | 3000 | 1 | Yes |

8LSA66.ee045ffgg-3 | 4500 | 1.5 | --- |

Cooling type C | Speed | Connector size | Single-cable solution (hybrid) available |

|---|---|---|---|

8LSC66.ee015ffgg-3 | 1500 | 1 | Yes |

8LSC66.ee022ffgg-3 | 2200 | 1 | Yes |

8LSC66.ee030ffgg-3 | 3000 | 1 | Yes |

8LSC66.ee045ffgg-3 | 4500 | 1.5 | --- |

8LSA7 / 8LSC7 - Availability

Cooling type A | Speed | Connector size | Single-cable solution (hybrid) available |

|---|---|---|---|

8LSA73.ee030ffgg-3 | 3000 | 1 | Yes |

8LSA73.ee045ffgg-3 | 4500 | 1.5 | --- |

8LSA74.ee015ffgg-3 | 1500 | 1 | Yes |

8LSA74.ee020ffgg-3 | 2000 | 1 | Yes |

8LSA74.ee022ffgg-3 | 2200 | 1 | Yes |

8LSA74.ee030ffgg-3 | 3000 | 1 | Yes |

8LSA74.ee045ffgg-3 | 4500 | 1.5 | --- |

8LSA75.ee015ffgg-3 | 1500 | 1 | Yes |

8LSA75.ee020ffgg-3 | 2000 | 1 | Yes |

8LSA75.ee022ffgg-3 | 2200 | 1 | Yes |

8LSA75.ee030ffgg-3 | 3000 | 1 | Yes |

8LSA76.ee015ffgg-3 | 1500 | 1.5 | --- |

8LSA76.ee030ffgg-3 | 3000 | 1.5 | --- |

Cooling type C | Speed | Connector size | Single-cable solution (hybrid) available |

|---|---|---|---|

8LSC73.ee030ffgg-3 | 3000 | 1 | Yes |

8LSC73.ee045ffgg-3 | 4500 | 1.5 | --- |

8LSC74.ee020ffgg-3 | 2000 | 1 | Yes |

8LSC74.ee022ffgg-3 | 2200 | 1 | Yes |

8LSC74.ee030ffgg-3 | 3000 | 1 | Yes |

8LSC74.ee045ffgg-3 | 4500 | 1.5 | --- |

8LSC75.ee030ffgg-3 | 3000 | 1.5 | --- |

8LSC76.ee030ffgg-3 | 3000 | 1.5 | --- |

All other lengths for size 7 are equipped with connector size 1.5 and therefore not available for the single-cable solution (hybrid).

8LSA8 / 8LSC8 - Availability

Size 8 motors (connector size 1.5) are not available for the single-cable solution (hybrid).

Connection direction

Connection direction

8LSA and 8LSC three-phase synchronous motors are available with 3 different connection options.

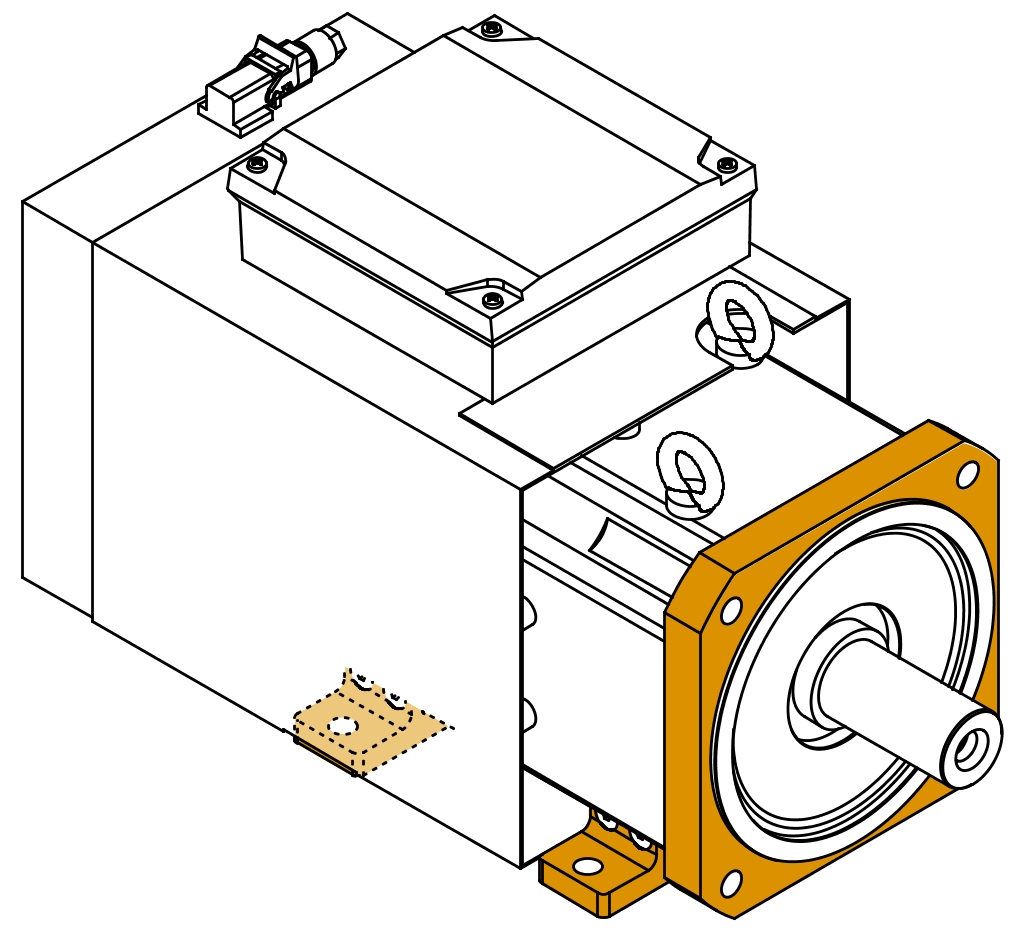

| Straight built-in connector Connection direction: Straight (top) Encoder and power cable: Separated with their own connections |

| Angled built-in connector Connection direction: Angled (swivel connector) Encoder and power cable: Separated with their own connections  Check the angle specifications (max. 200-220°) and the feasibility with regard to requirements using the CAD configurator (cad.br-automation.com). |

| Single-cable solution (hybrid) Connection direction: Angled, swivel connector Encoder and power cable: Combined in one cable  |

8LSC three-phase synchronous motors are only available at the factory with one possible fan connection direction.

| Fan connector Connection direction: Angled |

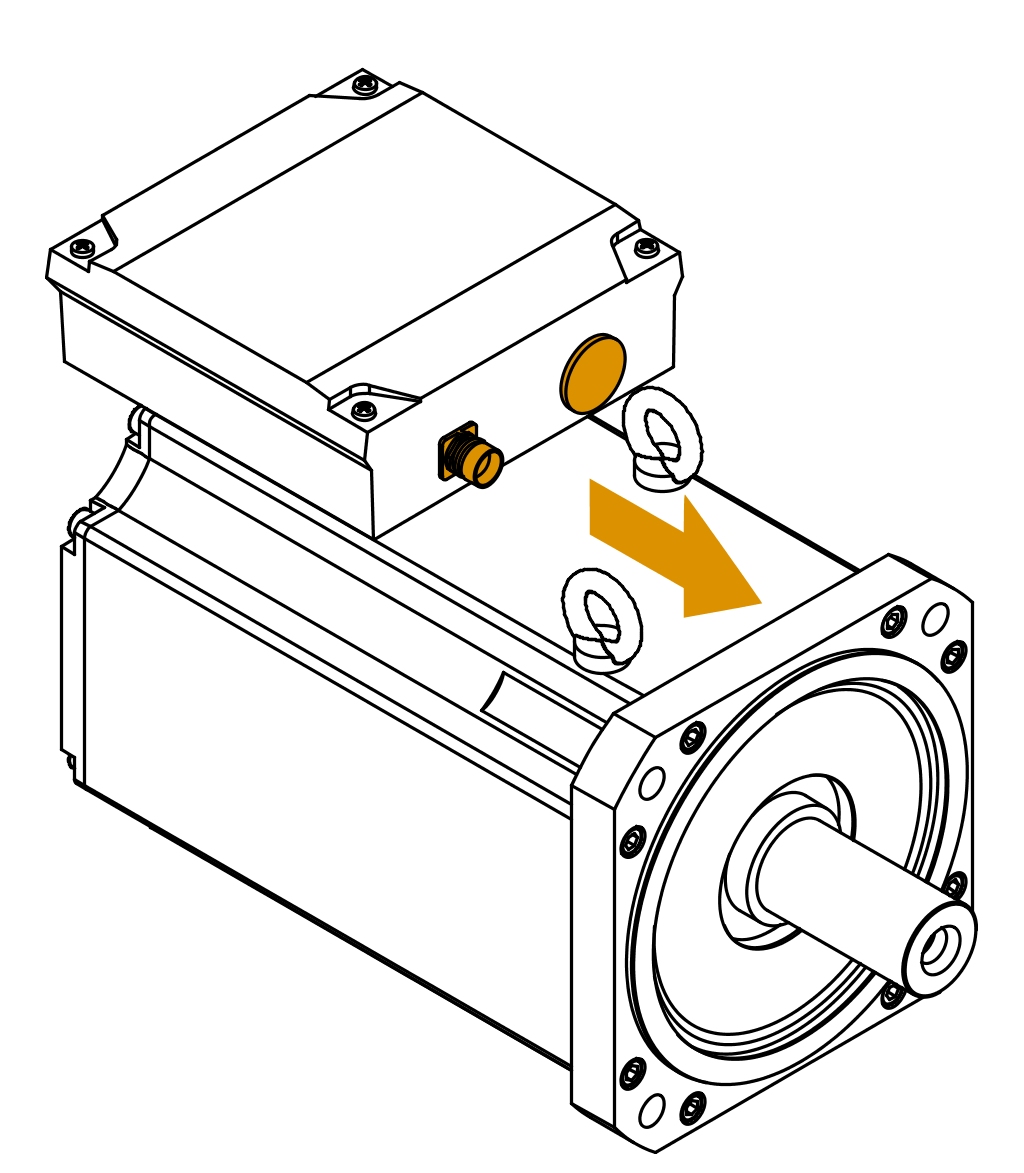

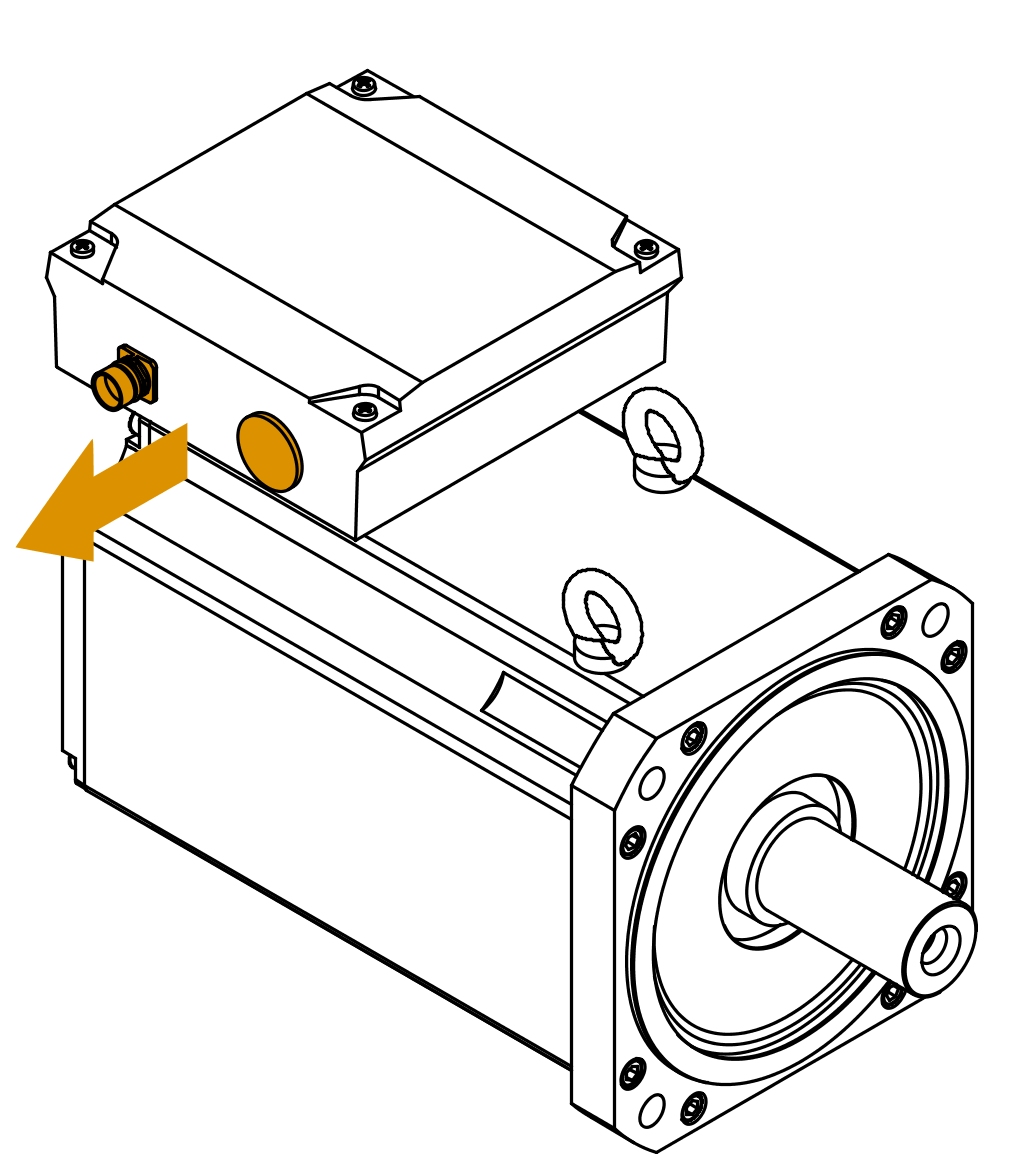

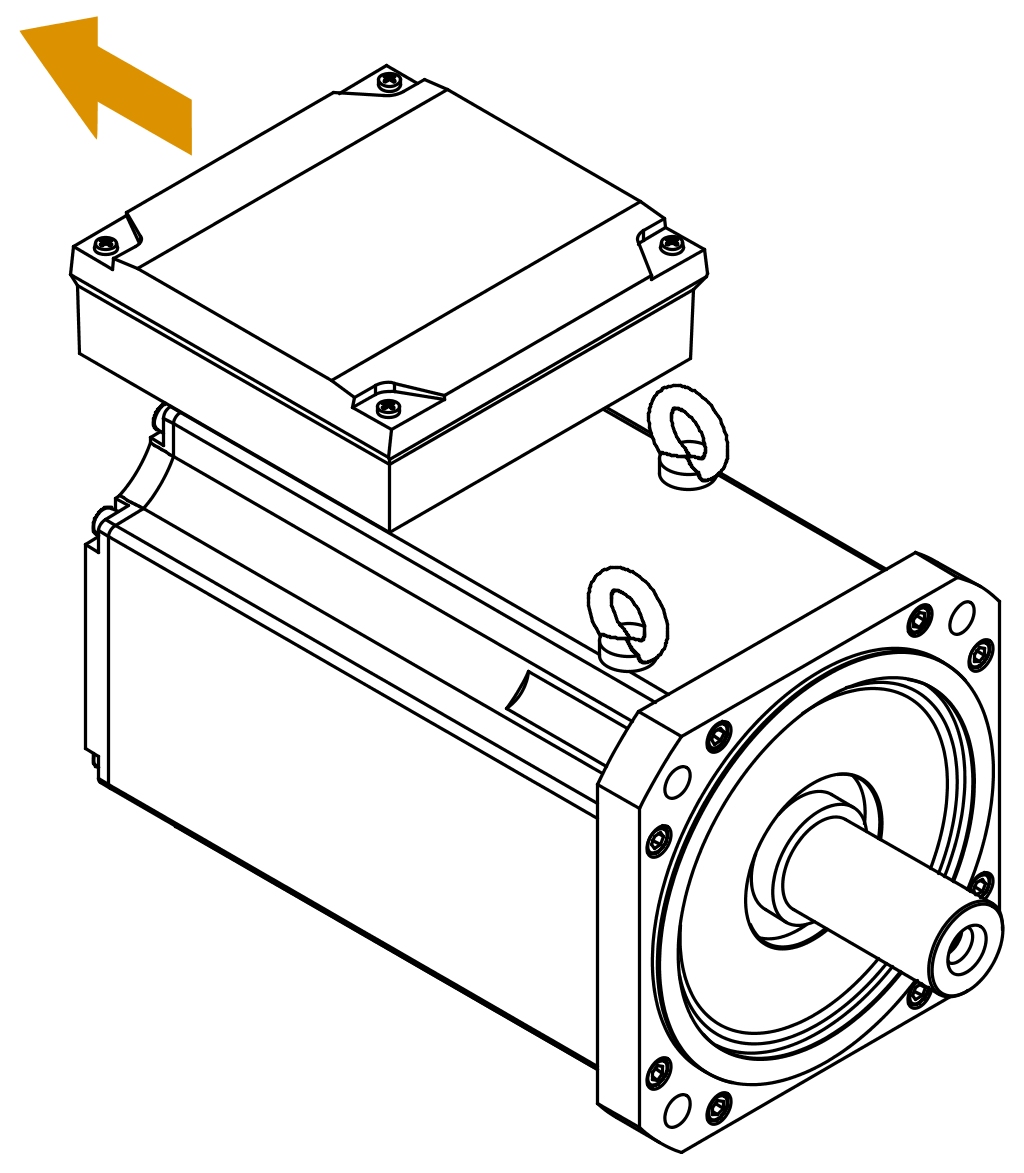

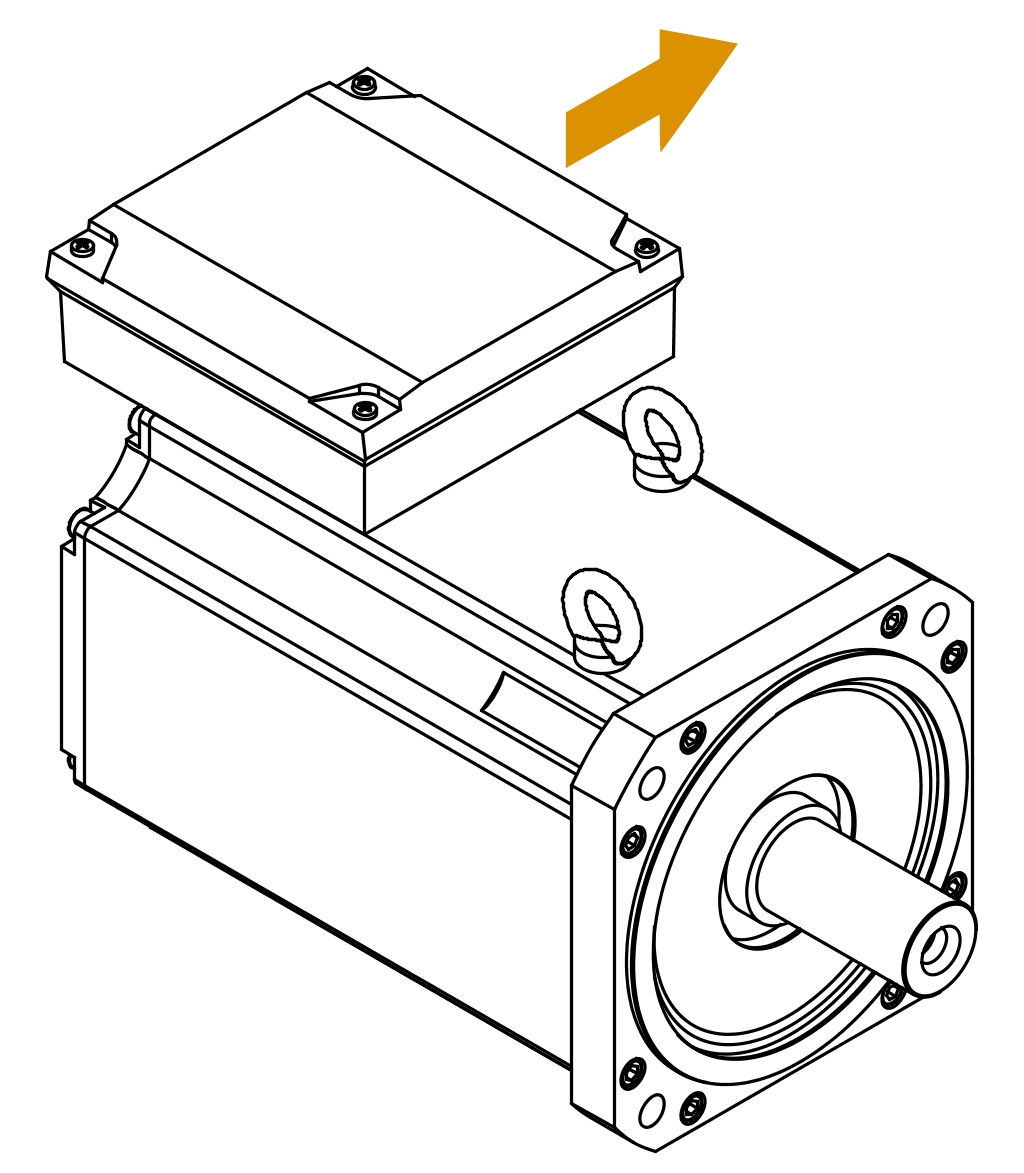

Other connection directions are possible, but must be implemented by the user. The junction box and cover with fan can be rotated in 90° steps; care must be taken to avoid a possible collision with the motor connections.

8LS | b | c | d | . | ee | nnn | ff | gg | - | h | |||||||||||

See the following table for the corresponding code (ff) in the order key.

Applies to all options:

The terminal box is always located on top; the cable outlet / connection direction is shown in the options table.

The encoder connection is straight and facing the connection direction.

Motor option | Availability | Order code (ff) | |||||

|---|---|---|---|---|---|---|---|

Installation type | Connection direction | Oil seal | Holding brake | Shaft end | 8LSO | 8LSP | |

Flange  | 270° (right)  | --- | --- | Smooth shaft | Yes | --- | A0 |

--- | --- | With key | Yes | --- | A1 | ||

Yes | --- | Smooth shaft | Yes | --- | A6 | ||

Yes | --- | With key | Yes | --- | A7 | ||

Flange/Foot  | --- | --- | Smooth shaft | Yes | Yes | B0 | |

--- | --- | With key | Yes | Yes | B1 | ||

Yes | --- | Smooth shaft | Yes | Yes | B6 | ||

Toothed shaft1) | |||||||

Yes | --- | With key | Yes | Yes | B7 | ||

Flange  | 90° (left)  | --- | --- | Smooth shaft | Yes | --- | E0 |

--- | --- | With key | Yes | --- | E1 | ||

Yes | --- | Smooth shaft | Yes | --- | E6 | ||

Yes | --- | With key | Yes | --- | E7 | ||

Flange/Foot  | --- | --- | Smooth shaft | Yes | Yes | F0 | |

--- | --- | With key | Yes | Yes | F1 | ||

Yes | --- | Smooth shaft | Yes | Yes | F6 | ||

Toothed shaft1) | |||||||

Yes | --- | With key | Yes | Yes | F7 | ||

Flange  | 180° (B-side bearing)  | --- | --- | Smooth shaft | Yes | --- | J0 |

--- | --- | With key | Yes | --- | J1 | ||

Yes | --- | Smooth shaft | Yes | --- | J6 | ||

Yes | --- | With key | Yes | --- | J7 | ||

Flange/Foot  | --- | --- | Smooth shaft | Yes | Yes | K0 | |

--- | --- | With key | Yes | Yes | K1 | ||

Yes | --- | Smooth shaft | Yes | Yes | K6 | ||

Toothed shaft1) | |||||||

Yes | --- | With key | Yes | Yes | K7 | ||

Flange  | 0° (A-side bearing)  | --- | --- | Smooth shaft | Yes | --- | N0 |

--- | --- | With key | Yes | --- | N1 | ||

Yes | --- | Smooth shaft | Yes | --- | N6 | ||

Yes | --- | With key | Yes | --- | N7 | ||

Flange/Foot  | --- | --- | Smooth shaft | Yes | Yes | P0 | |

--- | --- | With key | Yes | Yes | P1 | ||

Yes | --- | Smooth shaft | Yes | Yes | P6 | ||

Toothed shaft1) | |||||||

Yes | --- | With key | Yes | Yes | P7 | ||

| 1) | The "toothed shaft" is only available as a special motor option (gg) with code 44. See "Special motor options (gg) 8LSO / 8LSP". |

Mounting type

Mounting type

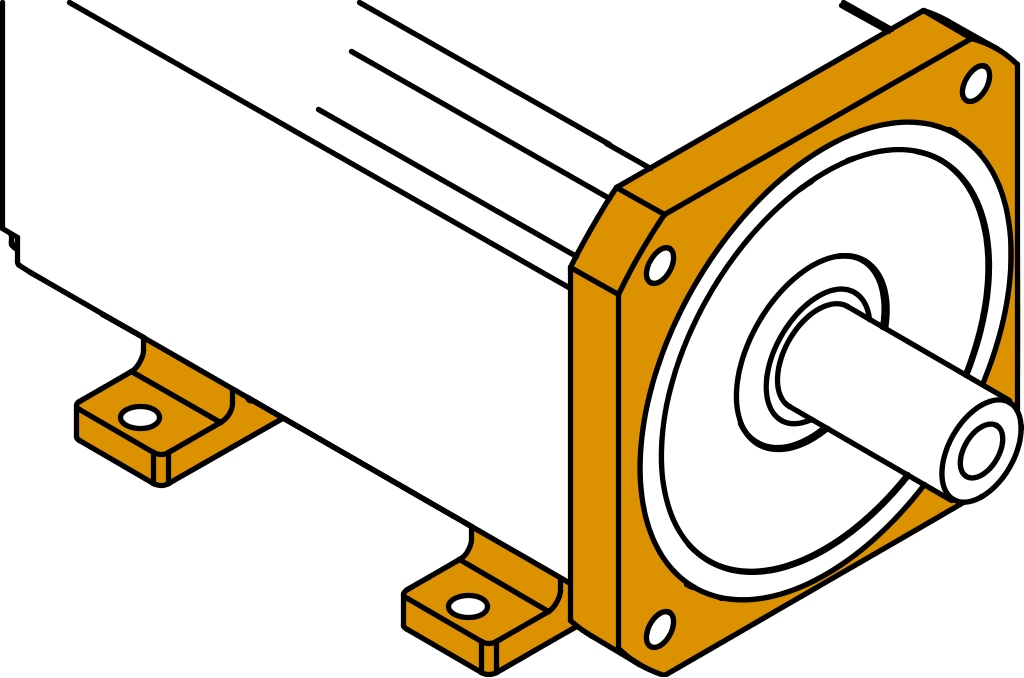

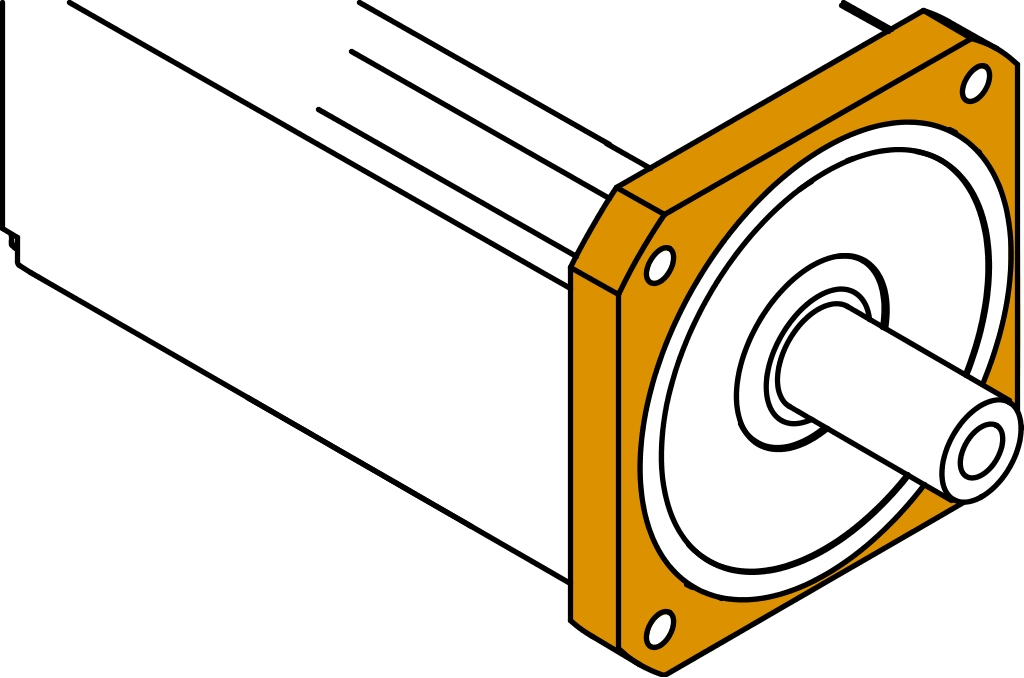

Cooling type 8LSO is available with the mounting flange as well as the mounting flange and mounting base.

Cooling type 8LSP is always equipped with a mounting flange and mounting base.

If the motor is equipped with a mounting flange and mounting base, then installation takes place either on the mounting flange or the mounting base.

Mounting flange | Mounting flange and mounting base | ||

|  |  | |

8LSO | 8LSO | 8LSP | |

Connection direction

Connection direction

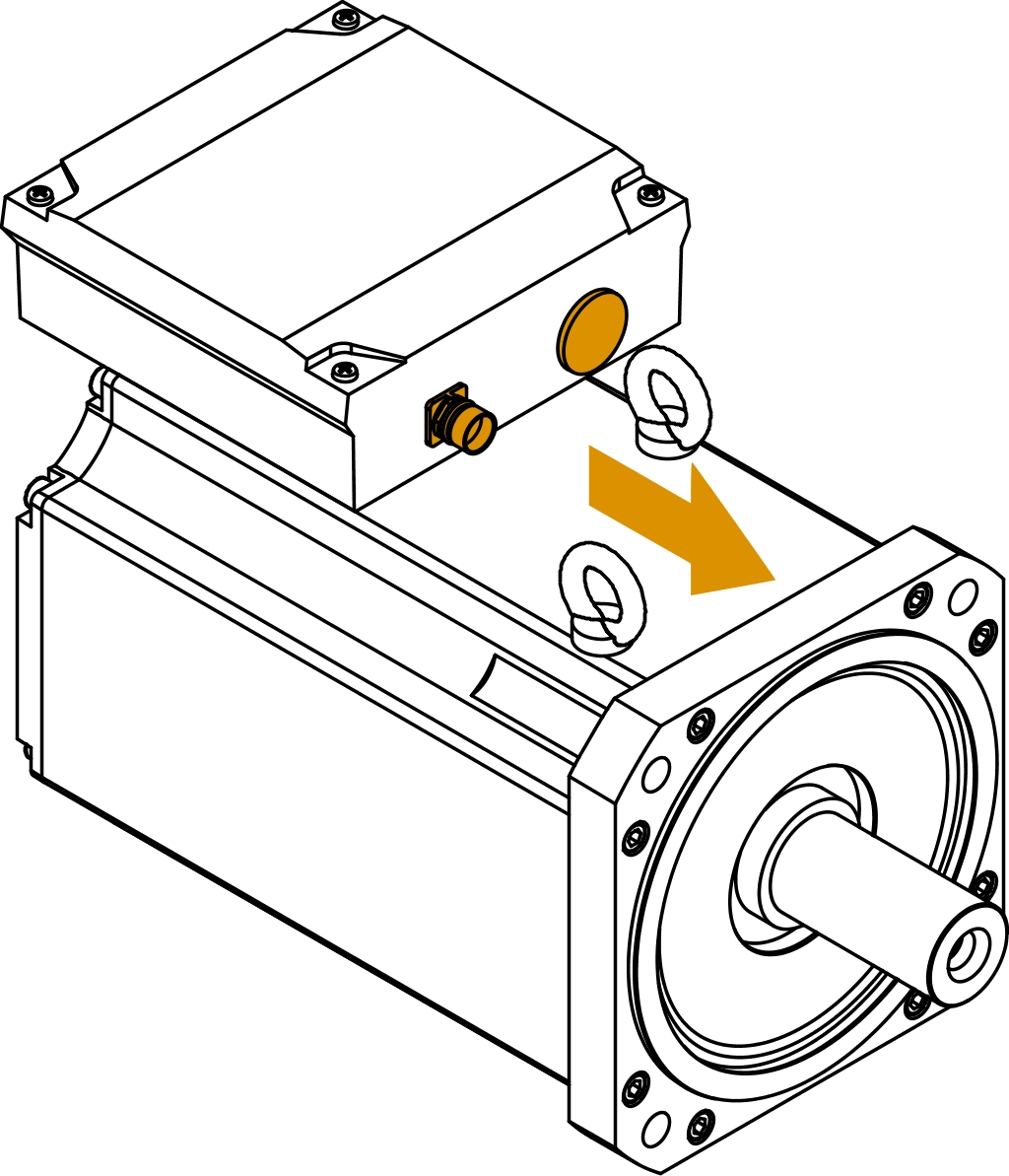

8LSO and 8LSP three-phase synchronous motors are available with a terminal box and 4 different connection directions.

0° |  90° |  180° |  270° |

270° | With the 8LSP three-phase synchronous motor, the fan connection direction is always 270°. |

Special motor options (gg)

8LS | b | c | d | . | ee | nnn | ff | gg | - | h | |||||||||||

The respective special motor option is specified as part of the order number in the form of a 2-digit code (gg).

The code (ff) for the motor options is limited by the special motor option (gg), or further codes (ff) are necessary when using the special-purpose holding brake. For the additional (ff) codes when using a special-purpose holding brake, see this section.

8LS | b | c | d | . | ee | nnn | ff | gg | - | h | |||||||||||

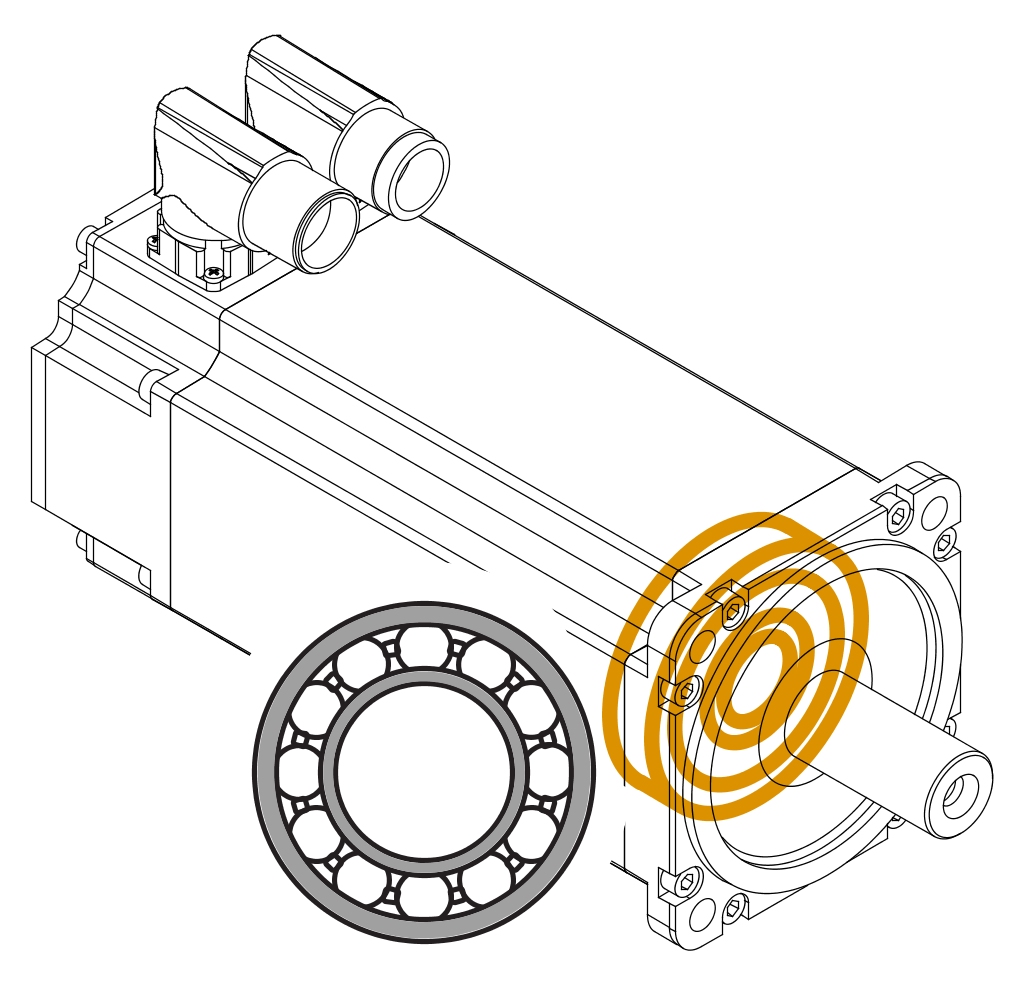

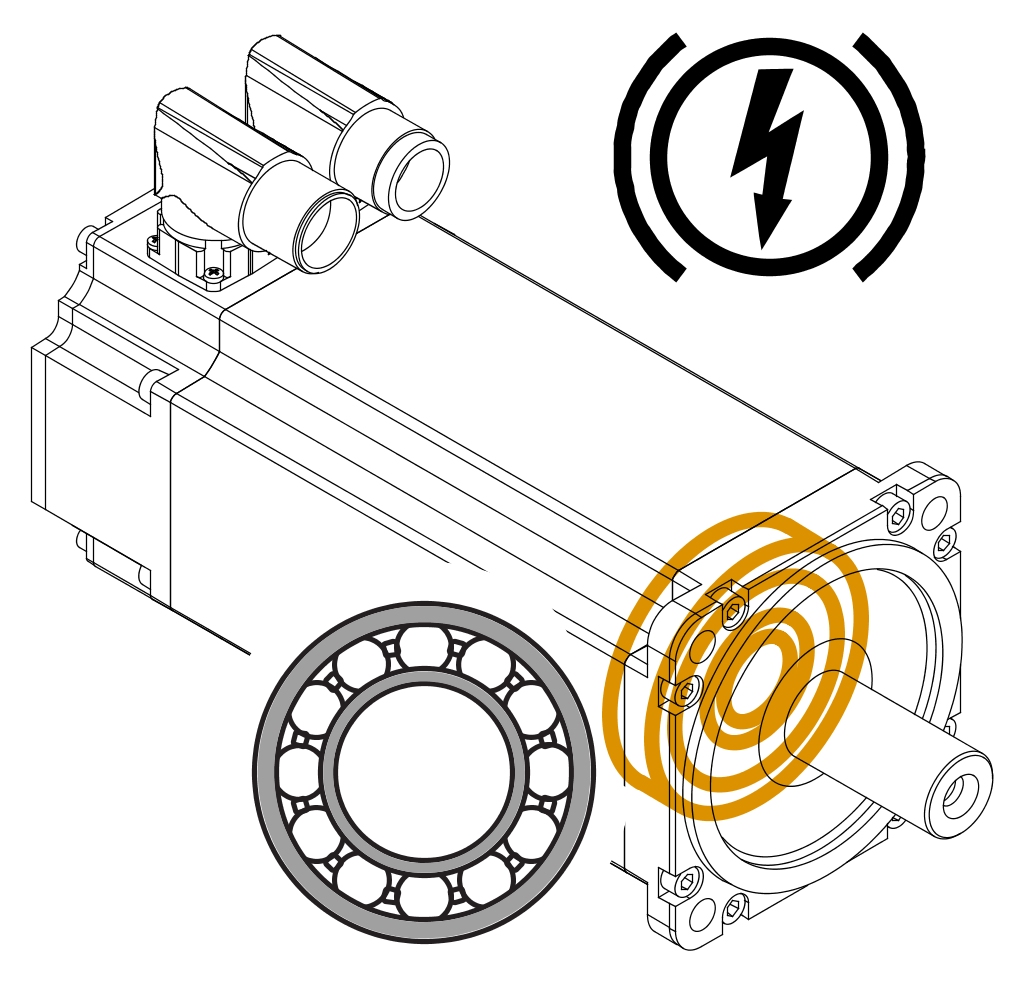

Reinforced A-side bearing

| 8LSA and 8LSC three-phase synchronous motors with sizes 4 - 8 are available with special motor option "Reinforced A-side bearing". |

Motors with special motor option "reinforced A-side bearing" have increased values for the dimensions of the motor shaft and the total length (in relation to motors with standard bearings).

For the exact dimensions, see the technical data of the respective 8LS three-phase synchronous motors.

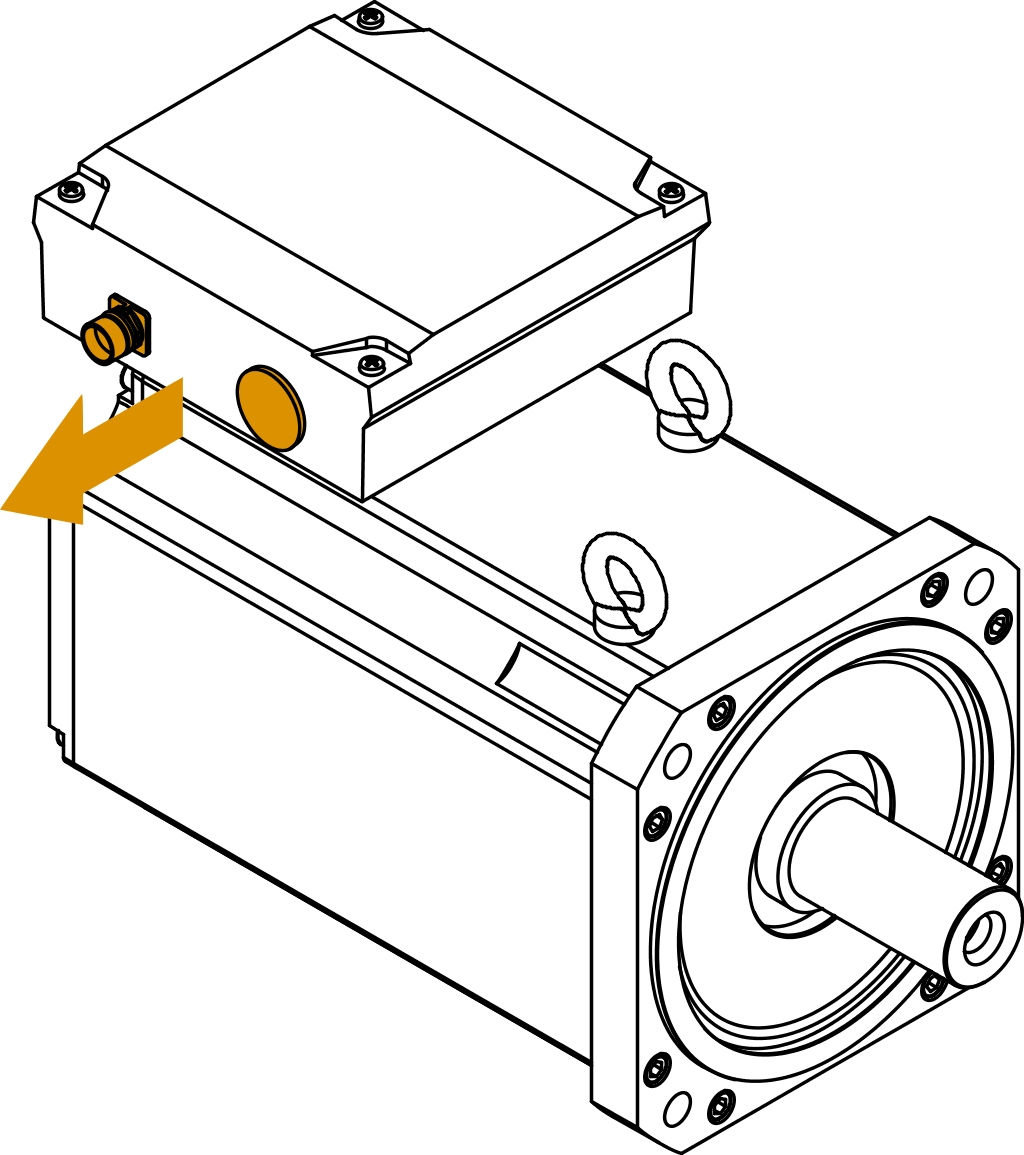

Fan 230 VAC

| Cooling type C (8LSC) can be equipped with the 24 VDC fan (standard fan) or 230 VAC fan (special motor option). |

Availability of special motor options

Availability of special motor options

The availability of the special motor options depends on the cooling type (8LSA / 8LSC), size (4 - 8) and motor option (ff). For the availability of special motor options, see the following tables.

Cooling type | Order code (gg) | Special motor option1) | Standard fan | 8LSA... | 8LSA... / 8LSC... | |

|---|---|---|---|---|---|---|

Reinforced A-side bearing | 230 VAC fan | ...2, ...A, ...3 | ...4, ...5, ...6, ...7, ...8 | |||

8LSA | 00 | --- | --- | --- | Yes | Yes |

8LSA | 04 | Yes | --- | --- | --- | Yes |

8LSC | 00 | --- | Yes | --- | --- | Yes |

8LSC | 05 | --- | --- | Yes | --- | Yes |

8LSC | 11 | Yes | --- | Yes | --- | Yes |

| 1) | Motor options "Standard holding brake" and "Increased holding brake" cannot be ordered in combination with special motor option "Reinforced A-side bearing". |

Permissible combinations

Permissible combinations

Permissible combinations (without holding brake)

The following combinations are available with special motor option reinforced A-side bearing (gg).

Order code | Options (ff) | Special motor options (gg) | ||||

|---|---|---|---|---|---|---|

(ff) | (gg) 8LSA | (gg) 8LSC | Connector direction | Shaft sealing ring | Shaft end | |

C0 | 04 (Self-cooled) | 11 (Standard fan 24 VDC) | Straight (top connector) | --- | Smooth shaft | Reinforced A-side bearing |

C1 | --- | Keyed shaft | ||||

C6 | Yes | Smooth shaft | ||||

C7 | Yes | Keyed shaft | ||||

D0 | Angled (swivel) | --- | Smooth shaft | |||

D1 | --- | Keyed shaft | ||||

D6 | Yes | Smooth shaft | ||||

D7 | Yes | Keyed shaft | ||||

S0 | Single-cable solution (hybrid) Angled, swivel connector | --- | Smooth shaft | |||

S1 | --- | Keyed shaft | ||||

S6 | Yes | Smooth shaft | ||||

S7 | Yes | Keyed shaft | ||||

Permissible combinations (with special-purpose holding brake for reinforced A-side bearing)

The following combinations are available with special motor option reinforced A-side bearing (gg).

Order code | Options | Special motor options (gg) | ||||

|---|---|---|---|---|---|---|

(ff) | (gg) 8LSA | (gg) 8LSC | Connector direction | Shaft sealing ring | Shaft end | |

CC | 04 (Self-cooled) | 11 (Standard fan 24 VDC) | Straight (top connector) | --- | Smooth shaft | Reinforced A-side bearing + Special holding brake |

CD | --- | Keyed shaft | ||||

CE | Yes | Smooth shaft | ||||

CF | Yes | Keyed shaft | ||||

DC | Angled (swivel) | --- | Smooth shaft | |||

DD | --- | Keyed shaft | ||||

DE | Yes | Smooth shaft | ||||

DF | Yes | Keyed shaft | ||||

SC | Single-cable solution (hybrid) Angled, swivel connector | --- | Smooth shaft | |||

SD | --- | Keyed shaft | ||||

SE | Yes | Smooth shaft | ||||

SF | Yes | Keyed shaft | ||||

Special-purpose holding brake for reinforced A-side bearing

Special-purpose holding brake for reinforced A-side bearing

| A special-purpose holding brake is required for special motor option "Reinforced A-side bearing" in conjunction with a holding brake. |

The holding brake is a permanent magnet brake and can be controlled by the B&R drive system. Based on principle, this type of holding brake exhibits a minimal amount of backlash. Voltage (see the technical data) must be applied to release the brake.

The brake is designed as a holding brake. It not permitted to be used for operational braking! Under these conditions, the brake has a service life of approximately 5,000,000 cycles (opening and closing the brake is one cycle). Loaded braking during an emergency stop is permitted but reduces its service life.

The required brake holding torque is determined based on the actual load torque. It is recommended by the brake manufacturer to take into account a safety factor of 2.

The holding brake is not intended for normal braking. The maximum motor torque far exceeds the holding torque for the brake.

If the holding brake should be used for the purpose of protecting personnel, the user must check via the MTTF values of the respective holding brake whether the performance level per EN ISO 13849 required for the respective application can be achieved with this holding brake. B&R recommends cyclical function testing of the holding brake.

8LSA4 8LSC4 | 8LSA5 8LSC5 | 8LSA6 8LSC6 | 8LSA71) 8LSC71) | 8LSA8 8LSC8 | |

|---|---|---|---|---|---|

Holding torque MBr [Nm] | 8 | 28 | 120 | ||

Connected load POn [W] | 16 | 26 | 50 | ||

Supply current IOn [A] | 0.67 | 1.08 | 1.51 | ||

Supply voltage UOn [V] | 24 (+6% / -10%) | ||||

Moment of inertia JBr [kgcm²] | 1.84 | 10.2 | 58.9 | ||

MTTF[h] | 12,060,000 | 48,760,000 | 5,510,000 | ||

| 1) | Only available for 8LSA73 / 8LSA74 and 8LSC73 / 8LSC74. |

8LS | b | c | d | . | ee | nnn | ff | gg | - | h | |||||||||||

The special motor option is specified as part of the order number in the form of a 2-digit code (gg).

No special motor option

If no special motor option is desired, the two-character code (gg) as part of the order number only provides information about the cooling type.

Order code | Standard fan | ||

|---|---|---|---|

Cooling type | (gg) | ||

8LSO9 | 00 | --- | No special motor option |

8LSP9 | 05 | Yes | |

| Toothed shaft for 8LSO / 8LSP The toothed shaft manufactured per ANSI B 92.1 is available as special motor option 44 for speeds 1300 and 1500. |

The toothed shaft is only available with special motor options (ff). Note that the code (ff) in chapter section "Motor options (ff) 8LSO / 8LSP" is specified with a smooth shaft, which becomes a toothed shaft due to special motor option 44, however.

Order code | Motor option (ff) | Standard fan | ||||

|---|---|---|---|---|---|---|

Cooling type | (ff) | (gg) | Mounting type | Connection direction | Oil seal | |

8LSO9 | B6 | 44 | Flange/Foot | 270° (right) | Yes | --- |

F6 | 90° (left) | Yes | --- | |||

K6 | 180° (B-side bearing) | Yes | --- | |||

P6 | 0° (A-side bearing) | Yes | --- | |||

8LSP9 | B6 | 44 | Flange/Foot | 270° (right) | Yes | Yes |

F6 | 90° (left) | Yes | Yes | |||

K6 | 180° (B-side bearing) | Yes | Yes | |||

P6 | 0° (A-side bearing) | Yes | Yes | |||

Motor version (h)

Motor version (h)

8LS | b | c | d | . | ee | nnn | ff | gg | - | h | |||||||||||

The motor version is specified as a code (h) in the order number. Motor version 3 is currently valid.

Example order 1

Example order 1

A three-phase synchronous motor of type 8LSA45 with a nominal speed of 3000 rpm was selected for an application. Because of the construction, the cables can only be connected on the top side of the motor ("top" connection direction). The motor should also be equipped with a holding brake, a keyed shaft and a 32-line EnDat single-turn encoder.

The code (ee) for the encoder system is EA.

The (nnn) code for a nominal speed of 3000 rpm is 030.

The code (ff) for the other options (oil seal, holding brake, keyed shaft and connection direction) is C3.

The order number for the necessary motor is therefore 8LSA45.EA030C300-3.

Example order 2

Example order 2

A three-phase synchronous motor of type 8LSA56 with a nominal speed of 4500 rpm was selected for an application. Because of the construction, cables can only be connected to the rear of the motor (swivel connectors). They should also take up as little space as possible. The single-cable solution (hybrid) is desired. The motor should also be equipped with a holding brake, smooth shaft, oil seal and 32-line EnDat multi-turn encoder.

The code (ee) for the encoder system is DB.

The code (nnn) for a nominal speed of 4500 rpm is 045.

The code (ff) for the other options (oil seal, holding brake, smooth shaft end and angled single-cable solution, swivel connector) is S8.

The order number for the necessary motor is therefore 8LSA56.DB045S800-3.