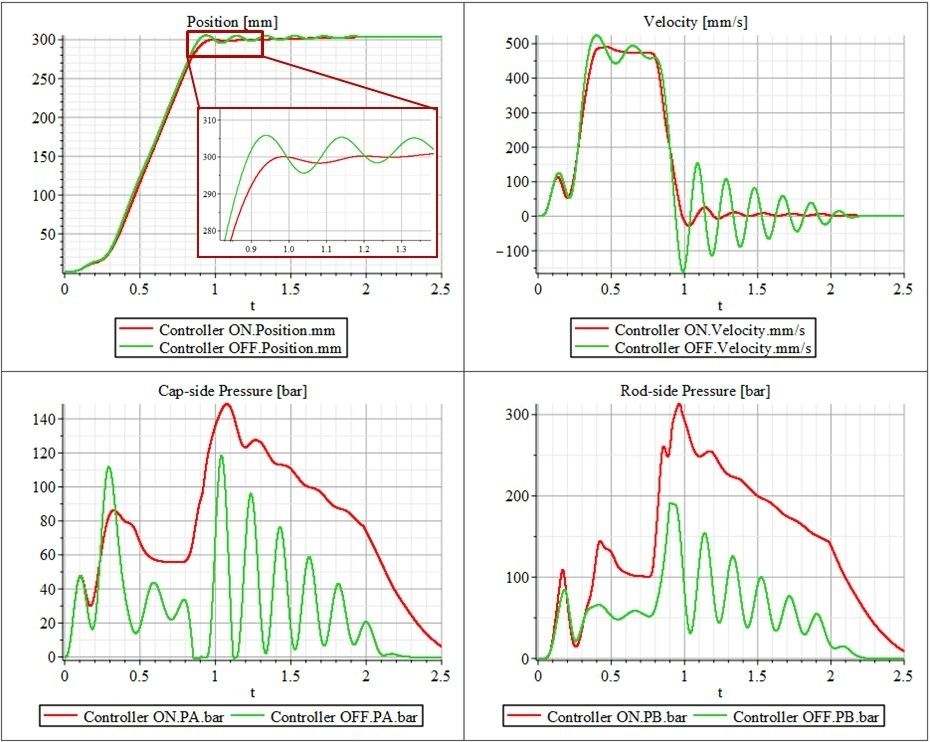

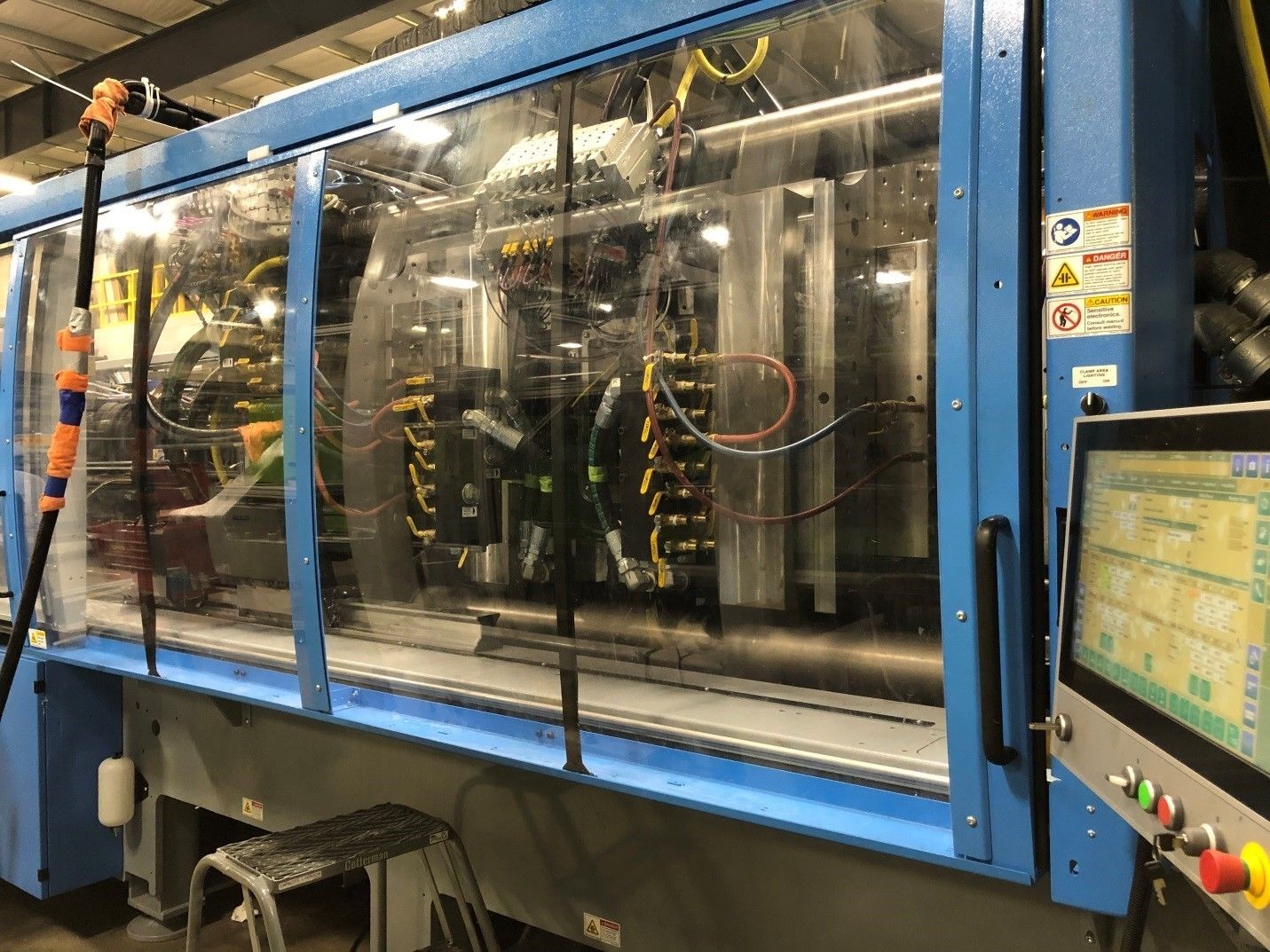

In a matter of months, machine simulation went from a hardly-considered option to an important tool for future engineering developments at Niigon. Marc Ricke, Niigon's controls engineering and IT manager, is confident in the added performance that simulation can bring to the product line: "We cut the machine's cycle time by 25% at less than a quarter the cost of a hardware solution. For me, it's a total no-brainer: You'll never get the best out of your mechanical system without simulation."

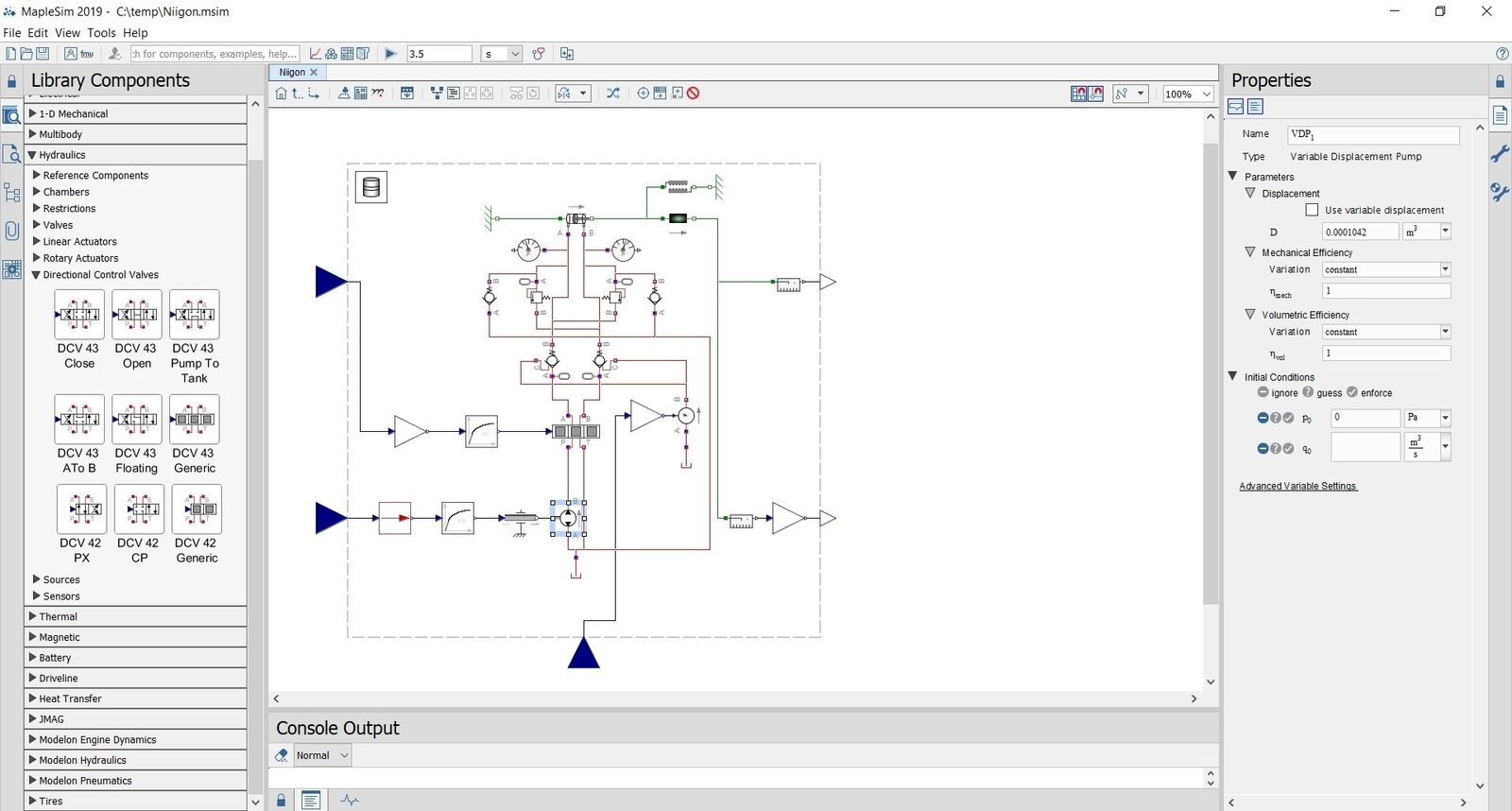

In future virtual commissioning projects, Niigon will continue to rely on Maplesoft Engineering Solutions for consulting, training and software, and B&R will continue to play a central role in automating the next generation of injection molding machines. "The excellent quality of service we received from Maplesoft's engineers, and the easy workflow between MapleSim and Automation Studio will help us offer our customers machines that achieve faster speeds with less expensive hardware," says Ricke.

What's next for Niigon? While they can't say exactly what is under development, simulation and digital twin development will certainly have a place in Niigon's engineering toolbox going forward. "In the early days of CAD modeling, there were some people who thought they'd be fine without it, yet today there's absolutely no debating its necessity," notes Ricke. "I expect that two years from now people here will look at simulation the same way."