"Thanks to flexible and open solutions, we can often implement applications on our own within a short period of time and according to the requirements of the production process."

Dipl.-Ing. Tomáš Magula, Electrical Engineering Manager, SEMIKRON

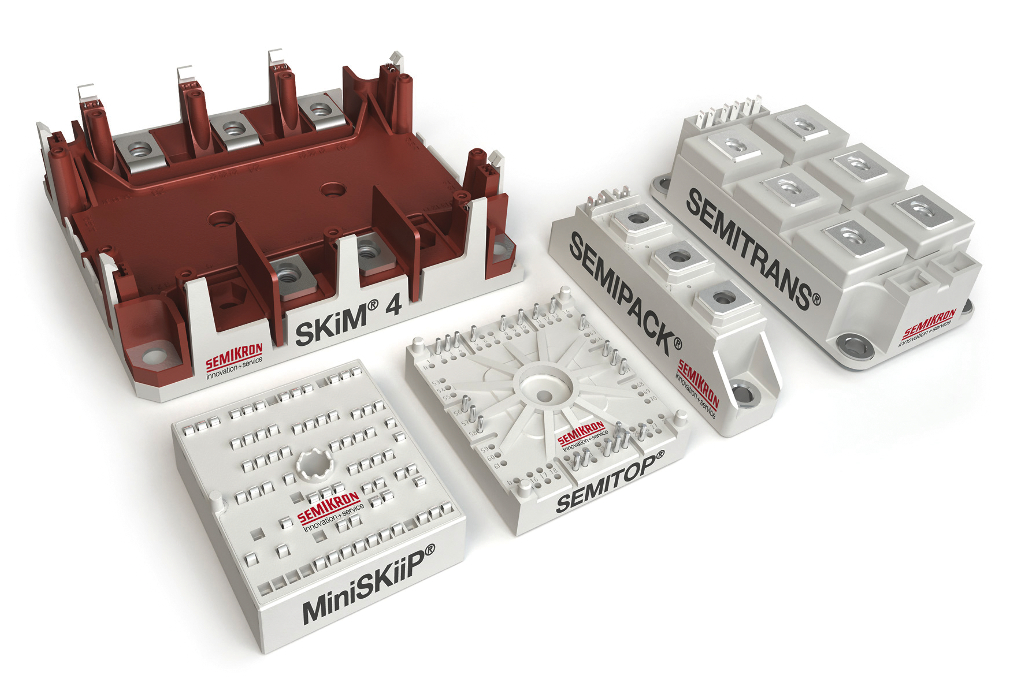

SEMIKRON, a family-operated company, is the market leader in the field of diode and thyristor modules, enjoying a 30% share of the worldwide market and found in almost half the wind power installations in operation worldwide. Together with B&R, they implemented an etching process that is managed entirely by a single Power Panel. Panels and ACOPOS servo drives control the entire system, communicate with the measurement stations and save intermediate data for a higher level system.

SEMIKRON meets all customer requirements with ten production plants worldwide and what is currently the second largest production plant for semiconductor components. Chip manufacturing requires the highest level of precision from every station in the production line.

The etching process implemented together with B&R is managed entirely by a Power Panel. Semiconductor chips are positioned using a pick-and-place system equipped with four ACOPOS servo drives and a 10.4" Power Panel. Panels equipped with ACOPOS servo drives control the entire system, communicate with the measurement stations and save intermediate data for a higher level system. For the current "measurement line" project, complete control of the console is being managed by two Automation PC systems. Through complete integration of safety functions in the automation system, openSAFETY ensures a safe and functional work environment for employees while reducing wiring at the same time.