Intelligent condition monitoring for the metalworking industry

Hall 12 / Booth B05 at the EUROBLECH exhibition in Hanover, Germany, will be the place to be as B&R presents APROL ConMon, the state-of-the-art solution for condition monitoring. The intelligent monitoring of machinery and plant states means reduced downtime in metalworking enterprises as well as the prevention of damage caused by unexpected defects. The result? Increased machine output and improved product quality.

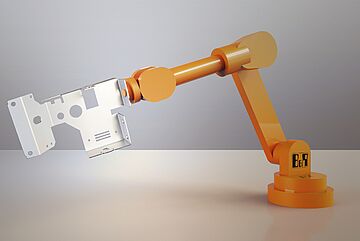

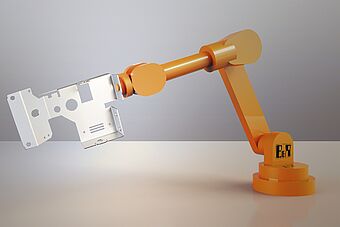

The latest solutions inspired by the vision of "Industry 4.0" will also be on display at the B&R booth. The ever-increasing trend towards the individualization of products makes it more important than ever to produce extremely complex sheet metal pieces in ever-decreasing quantities – all the way down to a batch size of 1. By combining CNC, robotics and general control tasks on a single hardware platform, the solution from B&R already has what it takes to overcome this challenge today.

Also being highlighted at the expo is B&R's comprehensive Automation Studio engineering environment, a tool that presides over the entire machine life cycle and considerably simplifies engineering processes all along the way. Instead of having to develop completely new machine variants for new target markets, nothing is easier than simply reusing the software on the new machine and integrating the necessary hardware from B&R's extensive range of modular building blocks.