Off-the-chart speed with an off-the-shelf solution

B&R reACTION distributes computational load to boost performance of time-critical processes

B&R reACTION distributes computational load to boost performance of time-critical processes

Digitalization brings big challenges for machine builders, but it also opens up new avenues to deliver value to their customers. Successful implementation, however, relies on easy access to shop floor data. With OPC UA FX, the future of digital services is open for business.

What determines the value of a product? In a growing range of industries, the answer is no longer hardware, but software. Anyone who has bought a car in the past 20 years can likely testify to this. First, electronic control systems came along and replaced the last few mechanical parts we could still repair ourselves with a wrench. Then came digital services such as driver assistance systems and cell phone integration. Today, connectivity is among the most important criteria considered by prospective car buyers.

A similar transformation is now sweeping through the machine building industry. What does that mean for our customers' machines? Easy: they want to implement the same kinds of connectivity and digital services that have long been standard in the world of IT and consumer electronics. As they do, the focus shifts from the machine itself to the processes upstream and downstream from it.

Batch-size-one production, adaptations via software update, troubleshooting via remote access, easy integration in end-to-end value chains: these are all services machine builders will soon need to offer if they wish to remain competitive. One of the challenges when implementing these services is achieving seamless communication between machines that use different control and communication systems. That same openness is also needed at the field level to collect data from the sensors and actuators on each machine.

Can a new communication protocol be the answer? No. In fact, it would be counterproductive to add yet another protocol to the existing clutter. The approach taken with OPC UA is much more promising: instead of another protocol, OPC UA relies on information models.

The main difference is in the structure. OPC UA information models provide semantically unambiguous definitions specifying exactly which space and which properties are assigned to which type of data. This makes the data machine-readable and allows it to be automatically developed into information.

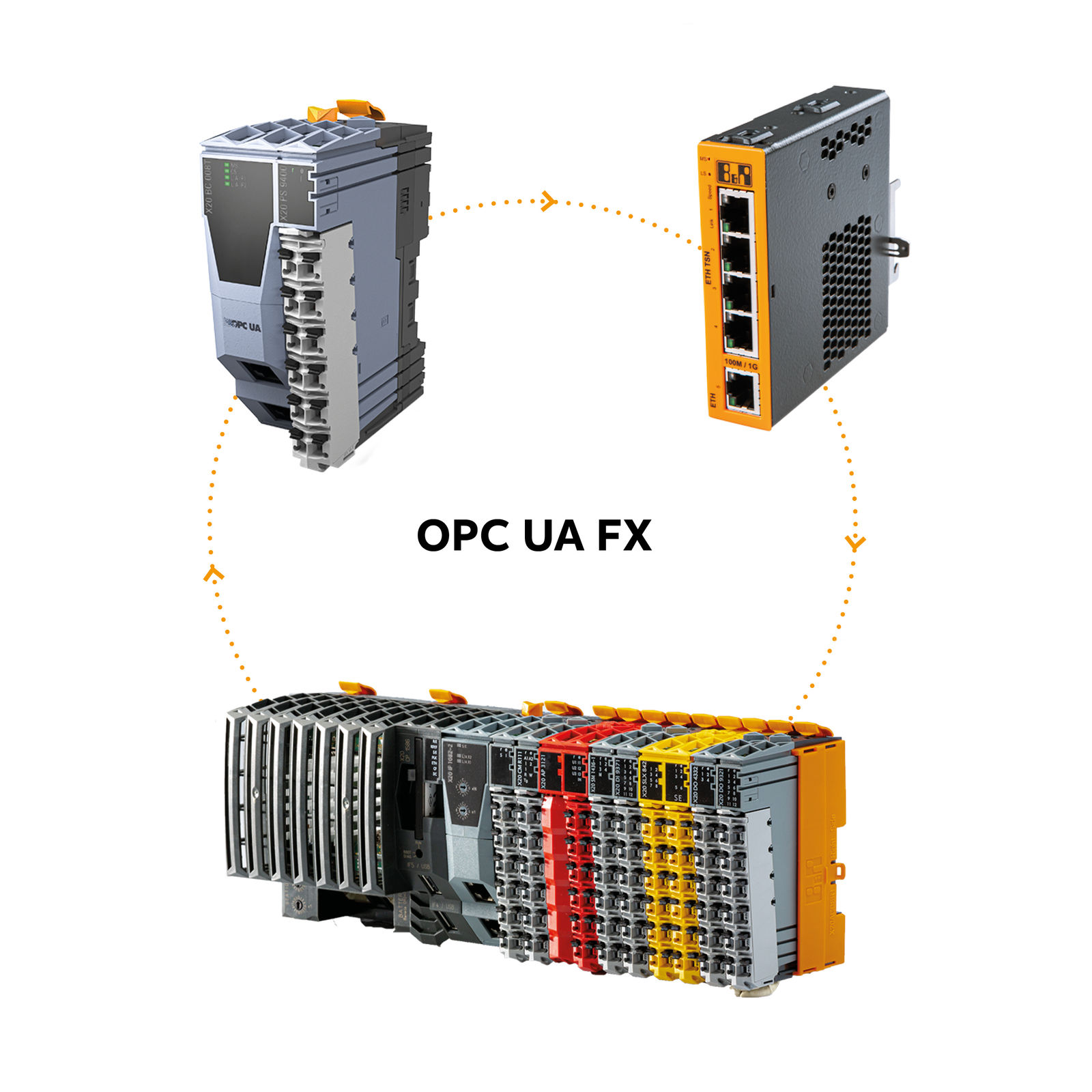

In 2016, the OPC Foundation launched the "Shaper" initiative to develop OPC UA over TSN – an open, standardized information model for seamless communication from the cloud down to the field level. Now referred to as OPC UA FX, the resulting solution is overseen by the Field-Level Communications (FLC) initiative of the OPC Foundation.

What does that mean for a machine builder? Simple: If you are planning a new machine series now, plan OPC UA FX right into it. More and more of our OEM customers are seeking support to implement their own digital business models and services. For their part, manufacturers are demanding machinery and equipment they can join together in a production network with the ease of plug-and-play. With OPC UA FX, there is now a uniform, open and global standard that enables machine builders to meet their customers' increasing demand for digital services.

And when it comes to product support for OPC UA FX: all doors are open. B&R's new bus controller is FX-ready, supports TSN and can be integrated into existing Ethernet networks. The same applies to the latest generation of X20 controllers. B&R has also developed a TSN switch, and upcoming versions of its Automation Studio software will support development of applications with OPC UA FX.

But FX is relevant not only for new machines, but for existing equipment as well. You can continue using familiar OT protocols in hybrid solutions, where both worlds coexist on the same network cable. What that means is that each machine builder can set the speed of their own transition to OPC UA FX – as long as they are prepared for it.

It's important to ask yourself what the market for your machines will look like ten years from now. The pressure from the manufacturing industry to get data-driven services has already hit machine builders and will only intensify in the years to come. As it does, powerful machine learning algorithms packaged in software apps will play an increasingly important role.

Digital solutions live on data. Data that needs to be acquired, processed, analyzed and – last but not least – transmitted. The necessary connectivity can be achieved through hours of extra engineering and investment in additional gateways – or simply by integrating OPC UA FX at the right time. In as little as five to seven years, OPC UA FX will dominate the world's production halls. Once the first stone falls, a domino effect will set in and flip the market on its head. Now is the time to make sure all your pieces are in place.

Bus controller | TSN switch | X20 PLCs |

|---|---|---|

B&R’s X20BC008U supports both OPC UA and TSN, opening the door for vendor-independent real-time communication at the line and field level. | The real-time-capable Ethernet switch streamlines implementation of OPC UA FX networks by making it easy to incorporate non-FX nodes. | B&R's latest generation of PLCs can be used as field-level masters in OPC UA FX networks. |