CNC technology expands the B&R drive solution with functionalities that enable multiple axes to be combined into groups and path-controlled movements to be executed.

Path-controlled movements are the basis for precise and complex workpiece manufacturing. In addition to a very wide range of interpolation methods, many technology functions are also supported.

The use of PLCopen-compliant mapp Motion components allows CNC technology to be seamlessly integrated into the machine application.

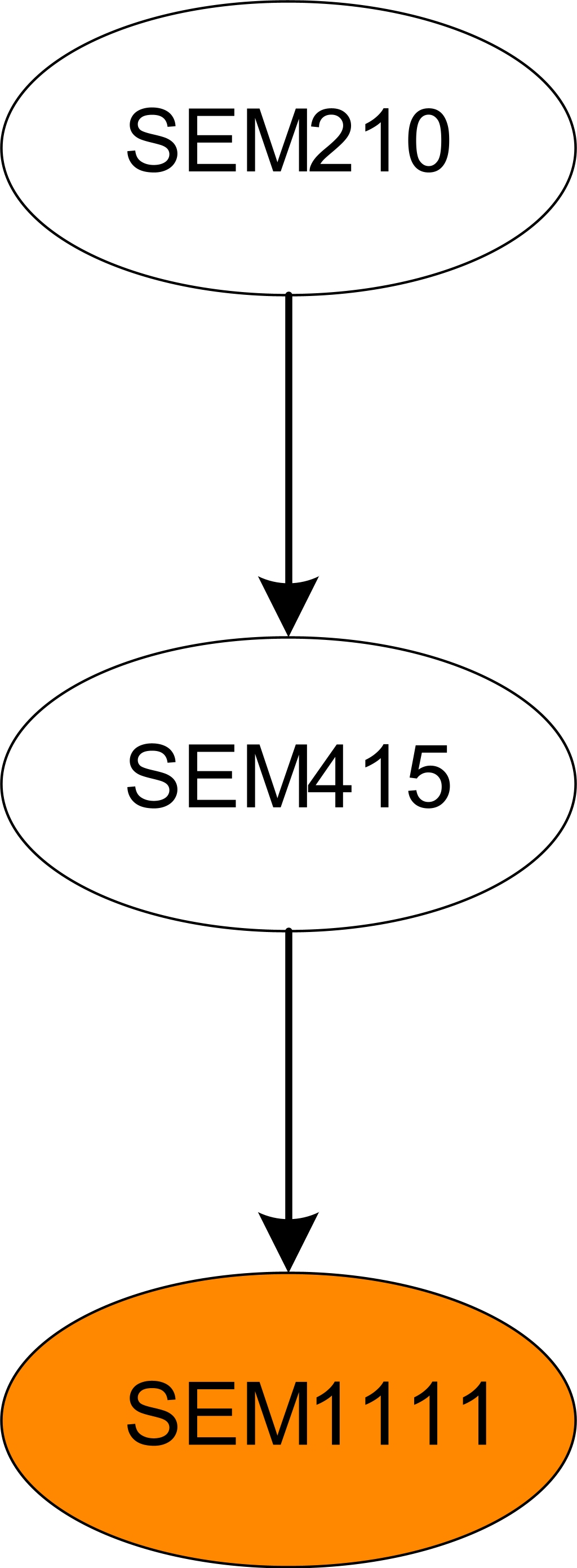

Requirements | Duration | Model number | |

|---|---|---|---|

Seminar Automation Studio training: Basics [SEM210.2] | 2 days | SEM1111.2 |  |

Learning objectives and content

- CNC terminology

- Overview of how an axis group works

- CNC configuration in Automation Studio

- CNC machine commissioning and diagnostics

- Application programming with PLCopen-compliant mapp Motion components

- CNC technology

- The basics of path-controlled movements

- Creating CNC programs

- Communication between a CNC program and the controller

Learning objectives and content

Tasks include

- Participants will put axes into operation and complete related diagnostics.

- Participants will manage a large number of axes in automation projects.

- Participants will integrate path-controlled axis movements in automation projects.

- Participants will create software used to execute CNC programs on a control system.