As industrial manufacturing processes grow more complex, increasing numbers of sensors flood the control system with input, while increasing numbers of actuators require highly precise output. When conventional SCADA and PLC solutions run up against their limits, what's needed is a fully integrated system to control, monitor and coordinate every aspect of production.

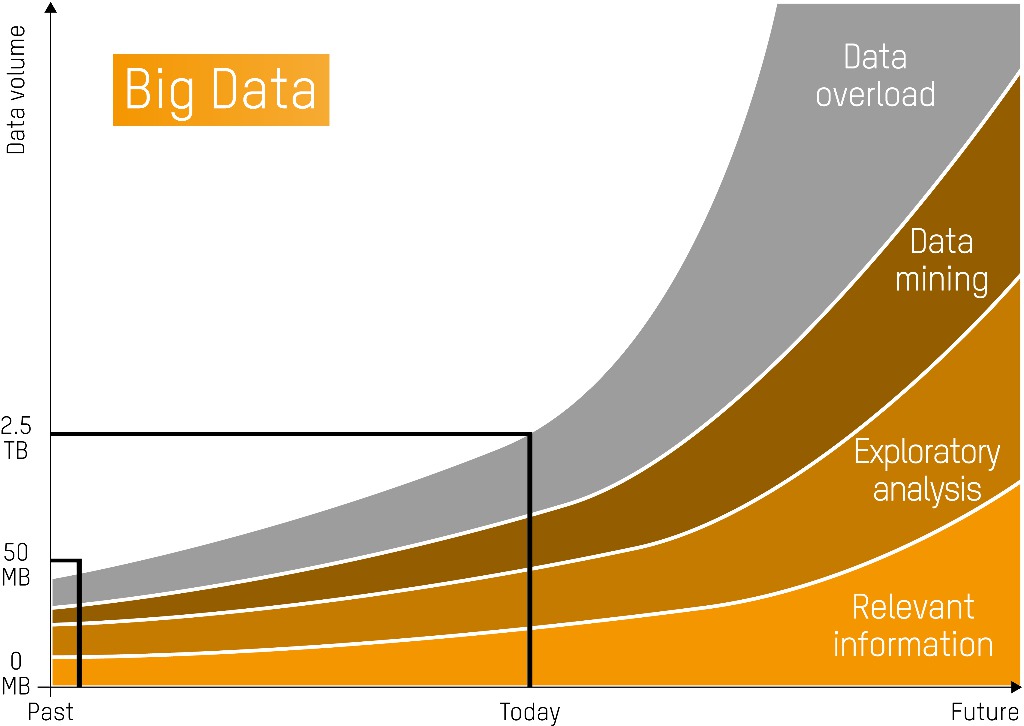

"The days when each machine and line in a factory could be treated like a self-contained unit are over," explains Martin Reichinger, manager of B&R's Process Automation business unit. "To name just one example: If you want to guarantee maximum productivity and product quality, then the packaging machine at the end of the line needs to coordinate with the filler at the beginning." Production processes have grown so complex that it is no longer feasible to configure and monitor key production parameters manually. Big data is a big challenge. Channeling and filtering the overwhelming flood of machine data, process data and operating data into coherent, actionable information calls for what is known as a manufacturing intelligence solution.

One solution for any manufacturing process

The other thing the market demands is flexibility. "You need to be able to make product changes on the fly with minimal setup," explains Reichinger. "That's the only way you can hold your own in today's market." Custom-printed bottles and packaging may be found in isolated marketing campaigns for now, but in a matter of years they will become the norm. Even small and mid-sized plant owners need to be thinking about how they are going to offer this level of flexibility. The only answer is a fully integrated solution that unifies control, monitoring and coordination of all aspects of production.

"For a long time, you would only find these systems in large processing plants," recalls Reichinger. It is this history that gave rise to the term process control system. Yet, the underlying principle of a process control system can just as easily be applied to any manufacturing process or infrastructure system.

Factory, process and infrastructure automation with APROL

The transition to a process control solution is notoriously complicated and costly. This has led many process control system suppliers to offer a separate system for factory automation and another for infrastructure automation in an attempt to clear the initial hurdle. "This approach presents plant operators with a major disadvantage," explains Reichinger. "They end up with three different systems, each generating its own costs for training, replacement parts and maintenance." That's why B&R took a different path with APROL. In a single, consistently easy-to-use platform, APROL unifies process automation, factory automation and infrastructure automation.

Scalable architecture

The APROL architecture is perfectly scalable. From a basic configuration with a controller and an industrial PC up to a complex client-server system featuring hundreds of controllers and dozens of runtime servers and operator stations – there is an ideal APROL architecture for any set of requirements. Should those requirements change, the system can be expanded modularly at any time to add new functions.

"Say you're already controlling a production plant with APROL, and down the road you determine that climate control is a relevant factor for your process," says Reichinger. "It's no problem to integrate control and monitoring of that equipment into the process control system to ensure optimal environmental conditions at all times." You don't need to purchase, install and maintain a whole new system. You don't need new software, and you don't need any additional control stations.

Systems with 50 to 200,000 I/O channels

With APROL, it makes no difference whether you're building a demo plant at a technical school with 50 I/O channels, or a large-scale infrastructure project with 200,000. The architecture can even be expanded during operation. For specific applications such as energy monitoring, condition monitoring and advanced process control, APROL offers out-of-the-box solutions that come preinstalled, preconfigured and ready to use. "APROL delivers all the advantages of process control without demanding specialist knowledge," says Reichinger. These solutions can be expanded into a full-fledged process control system at any time without having to switch to a new system.

Redundancy at every level

In many processes, high availability must be guaranteed in order to avoid costly downtime. Such plants rely on complete system redundancy. In an APROL system, the fieldbus, controller, process bus, runtime server, operator bus and operator stations can all be laid out redundantly. If the active system fails, a system running in parallel takes over all of its tasks with zero disruption. This prevents production downtime, improves process reliability and ensures consistent output quality. It also prevents any gaps in data acquisition, which ensures comprehensive and seamless documentation of the entire manufacturing process. "Since no special hardware is required, a non-redundant system can made redundant at any time. This makes every component a 100% secure investment," explains Reichinger.

"With B&R's APROL automation platform, you have one easy-to-use system that incorporates factory automation, process automation and infrastructure automation." Martin Reichinger, Business Manager of Process Automation, B&R

Open standards reduce risk

Bringing machines and lines from multiple manufacturers together to form a well-functioning factory is normally a job for a systems integrator. Interfaces are required so that these machines can communicate not just with one another, but with a supervisory-level control system such as SCADA. "B&R offers a completely uniform solution for this," explains Reichinger. APROL supports all of the most common fieldbus technology, allows connection of third-party controllers and supports open standards like OPC, OPC UA, PLCopen and PackML. The inconvenience and potential for errors that come with programming custom interfaces are all but eliminated.

Seamless acquisition and documentation of process data

"More and more companies are finding themselves obligated – whether through legal standards or customer contracts – to provide rigorous documentation of their manufacturing processes," notes Reichinger. While this phenomena has traditionally been limited to the food, beverage and pharmaceutical industries, today you'll also find automotive manufacturers, for example, requiring that their suppliers provide a comprehensive part history for each and every component. "Not only does a process control system record all relevant production data, it also keeps a history of every operator action and a logs every warning or alarm ever generated. It's the perfect tool for the job," says Reichinger. B&R's process data acquisition solution, APROL PDA, is available as an integrated feature of the APROL process control system or as a preconfigured standalone package.

Creative data exploration

Traditional analysis methods based on rigidly defined reports are gradually giving way to more creative exploratory approaches. When dealing with large data sets whose correlations are not fully understood, exploratory data analysis is an approach that uses graphical visualizations to provide insight and help form hypotheses. With access to data from all sources, the analysis can expose important cause-and-effect relationships. APROL features a comprehensive selection of reporting and analytical tools able to generate custom reports at the push of a button. Designing a custom report is as easy as using drag-and-drop. Ad-hoc reports, dashboards and mobile access with server-side authentication ensure that the information you need is available when and where you need it. You don't need to be an IT specialist to figure it out, either. "The analytical and reporting features really round off the APROL automation platform. They are a key part of what makes it the ideal tool for meeting the challenges of the future head-on," says Reichinger.