B&R's powerful vision system sets new industry standards: The cameras, intelligent image processing algorithms and innovative lighting portfolio are an integral part of the control system.

Several exceptional features characterize our machine vision solution. The relation of processing power to camera size and cost is extraordinary. A few years ago, the industry could only dream of this kind of performance with such a compact camera. By combining multiple functions in one housing, machine builders and end users can save time and money.

All features can be combined individually. This makes it possible to configure the right system for any application. Get an overview of the possibilities available with B&R's adaptive vision system.

The B&R vision system can be customized to your needs with several camera, lighting or filter options that will help you achieve game-changing results. →

The vision system offers a range of outstanding features that provide completely new perspectives for your applications. →

The cameras, intelligent image processing algorithms and innovative lighting system are all integral components of the control system. →

Algorithms based on deep learning are opening up exciting new ways to improve quality, boost productivity and prevent waste while making manufacturing more flexible. →

A system that enables simple maintenance is key to minimizing machine downtime and maximizing OEE at the same time. →

A complete portfolio of cameras, lenses, lighting and software provides the right solution for any application. →

Countless camera variants – Perfect for every application

Each vision sensor or camera can be configured individually – fully adapted to the machine process. It's possible to customize your order to your needs starting by deciding between a sensor, camera or deep learning camera. From there, you can choose from a wide range of focal lengths, illumination colors and many more variants.

- Calibrated or electronically adjustable lens focus

- 7 different integrated lenses as well as a flexible c-mount variant

- 3 variants of sensor resolution, from 1.3 to 5.3 MP

- 7 LED variants with up to 4 different colors

Extensive lighting portfolio

The selection of flexible light bars, ringlights and backlights ensure optimum results even in difficult lighting situations. Each light has an integrated flash controller, so no external hardware is required. Lighting control is synchronized with the automation system in the sub-μs range.

As the only manufacturer on the market, B&R equipped its light bars with electronic angle adjustment from -45° to +90°, via the fieldbus connection. When producing multiple products on the same machine, the lighting angle can be automatically and reliably optimized for each batch.

- 6 backlight and 7 light bar variants

- Lighting control with µs precision

- Immune to extraneous light

- Integrated strobe controller

- Calibrated light source for reproducible radiant flux

Adaptive lights to unveil the invisible

Intelligent lights that can seamlessly adapt to your products in real-time, allow you to unveil the invisible. Each light can feature up to four different LED colors. The selection ranges from white and various visible colors to invisible colors. Infrared or ultraviolet LEDs can be used to make structures disappear or become visible.

By using complementary lighting in different applications, maximum intensity and contrast can be achieved. At the same time, the right color combination ensures minimum exposure time and smearing.

- 4 out of 7 different LED colors in one light (red, green, blue, lime, white, infrared, ultraviolet)

- Real-time color adaptation made possible by an integrated control system

- Available as integrated camera lighting or an external smart backlight, light bar or ringlight

Detecting fine 3D structures on surfaces

The FPGA-based image preprocessing function Shape from Shading opens up a wider range of applications for B&R vision sensors and smart cameras. Shape from Shading captures multiple images with different illumination angles to visualize fine 3D surface structures such as embossed writing or scratches.

- Serve a wider range of applications

- Higher accuracy grants product quality

- Development time reduction

- More flexibility and higher productivity

No limits with multifunctional vision sensor

Unlike many other devices in its class, there is no need to install different sensors for different functions. Instead, users simply configure the Smart Sensor in the Automation Studio engineering tool, where they can choose from a large selection of functions. Up to 255 models can be stored and executed on a sensor. Additional models can easily be exchanged in the software.

- Countless features in one vision sensor

- Identical hardware for different applications

- Less need for spare parts

- Function defined in automation project, not by item number

- Transparent costs, independent of software functionality

High-speed objects perfectly illuminated

Each light has an integrated flash controller, so no external hardware is required. The controller ensures a precise pulse current supply to the powerful LEDs: Already with a pulse duration of 1 µs, the light reaches 100% intensity.

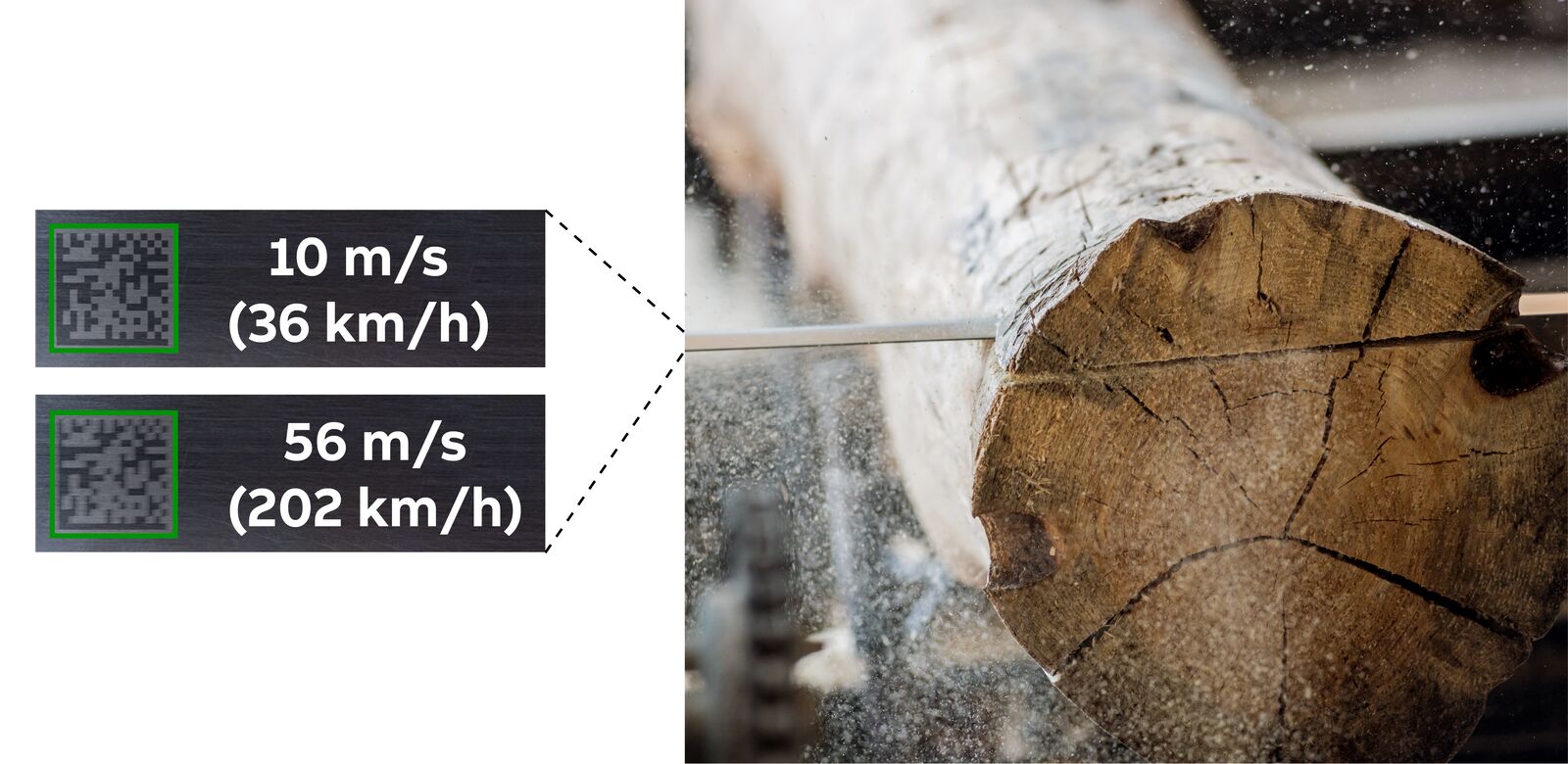

Unlike conventional image processing systems, the B&R vision system can therefore also be used in high-speed applications without any problems. We recently realized an application where the system reads a data matrix code on a band saw blade at 56 m/s speed. Also, the high-performance lighting eliminates almost entirely the influence of extraneous light - a crucial quality factor.

- Maximum intensity and homogeneity

- No chance for extraneous light

- Automatic adaption to every situation

- Repeatable intensity due to factory calibration

Filters for improved image quality

Additional filters are a simple and inexpensive way to further improve the quality of captured images. A polarizing filter can eliminate reflections and glare and a collimating filter ensures optimum contrast.

- Elimination of reflections and glare

- Perfect contrast in every situation

- Use for challenging surfaces (e.g. metallic)

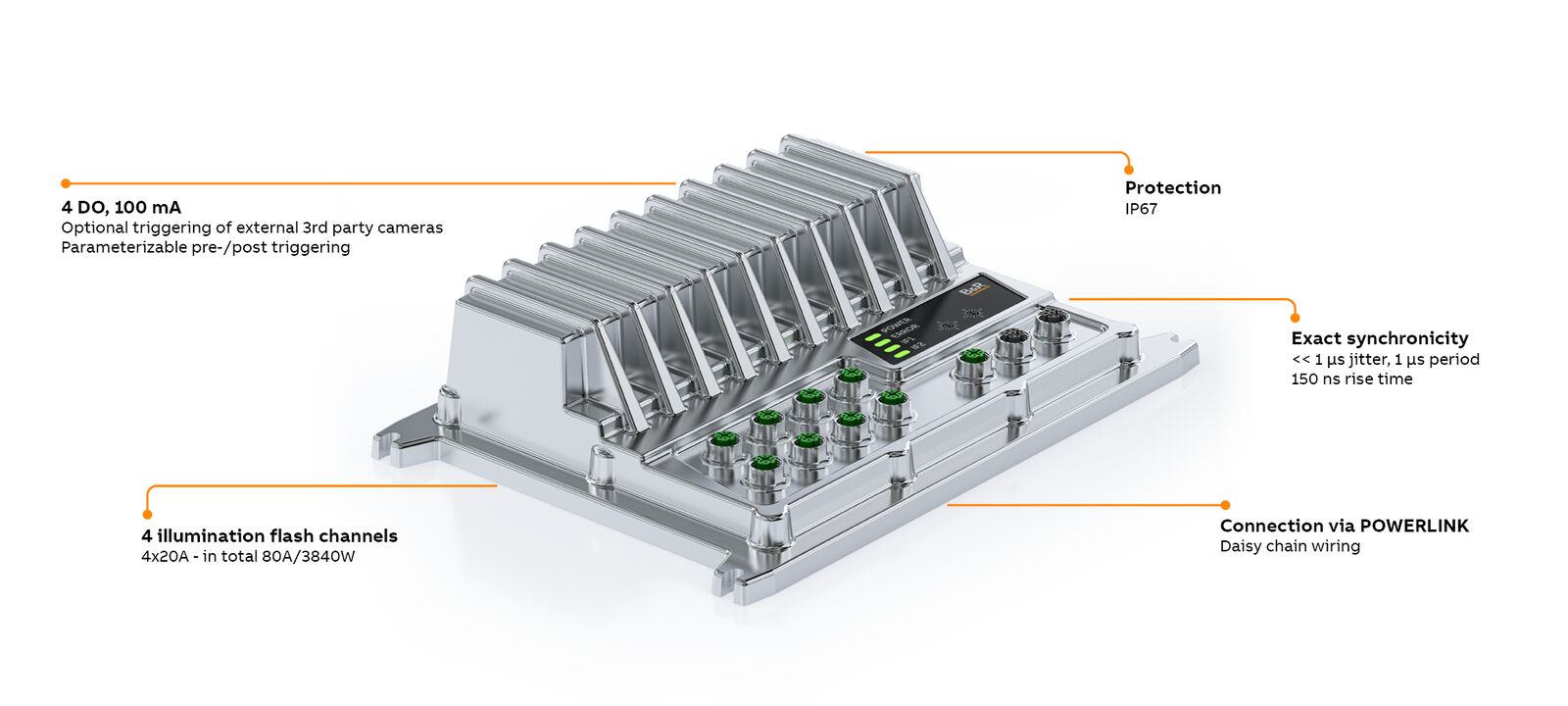

Flash integration with no compromises

With the B&R Flash Controller, any external current-driven lighting system works as if it were an integrated B&R Smart Light. This system offers single-wire connections without needing additional trigger sensors. It provides µs-accurate synchronicity to the entire B&R system, incredibly fast flash current rise times and maximum power during the entire flash period. What's more, costs are saved due to reduced cabinet space, fewer cables and shorter cable lengths.

- Open to use 3rd party light device

- Lower development risk

- Solve challenging vision tasks

- Cabling cost reduction

- Higher repeatability, productivity and quality

Detecting smallest deviations

The FPGA-based image preprocessing function Subtraction opens up a wider range of applications for B&R vision sensors and smart cameras.

Smallest deviations can be detected by comparing one or more images against a reference image. The function is used for tasks such as quality control to detect differences. Another use case can be speed measurement.

- Development time reduction

- Higher flexibility and productivity

- More CPU resources for subsequent image processing tasks

Solving 3D tasks at 2D costs

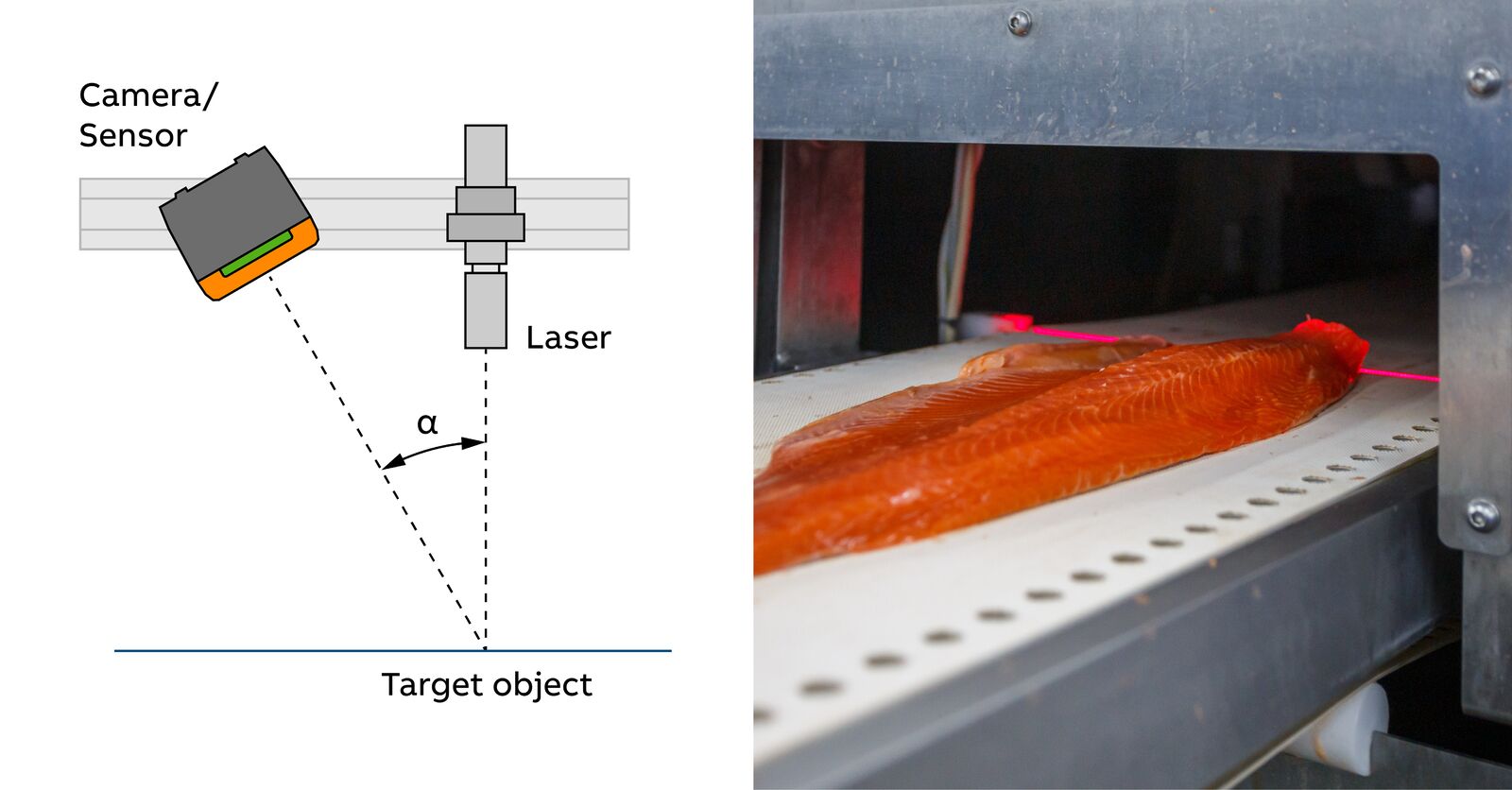

A new function for B&R's standard 2D vision sensor makes it possible to obtain profiles of moving objects using intelligent triangulation algorithms.

It's possible to estimate volume, map the course of height or valley profiles, and more. Typical 3D tasks can be solved resource-efficiently with the right image representation and intelligent 2D algorithms. In other words: 2.5D.

- Easy implementation of advanced vision functions

- Cost savings for a wide range of applications

- Flexible usage for different measuring ranges

Next-level vision functions

Flexible image processing for greater productivity: New vision functions take on specific image processing tasks – individually in a vision sensor or as a function sequence in a smart camera.

By integrating HALCON program code into an intuitive user interface, the vision functions make it easy for automation programmers to configure modern image processing functions and integrate the results into the machine application. Image processing is more flexible and productive than ever.

- Simple matching – an alternative to edge-based standard matching, when an image should be trained by the application directly; with the highest accuracy.

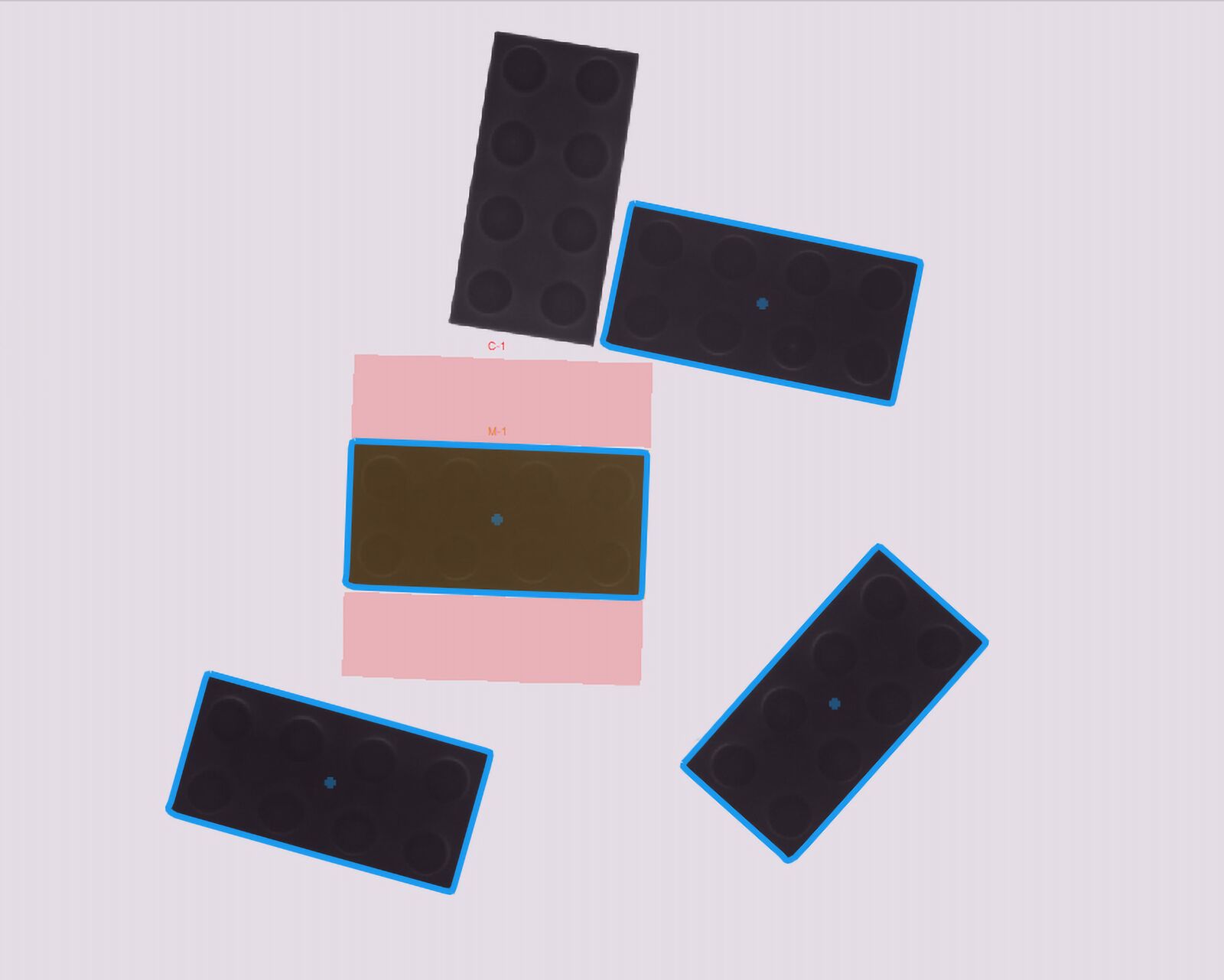

- Clutter matching – an area within or near a matching hit can be defined in which no clutter is permitted, e.g. for pick-and-place applications. The robot grips the component only if the highlighted area is free of other components – see image on the right.

- Camera calibration – the function corrects perspective-related errors or optical distortions by converting pixel values into metric values; e.g. for hand-eye calibration in robot applications.

- Image processing – with "image manipulation", additional filters and image processing steps can be easily added; to read curved fonts for example.

- Logic and math – with this function, the intermediate results of one or more image processing functions can be used directly on the camera to control subsequent image processing steps.

SYSTEM INTEGRATION

Seamlessly integrated into the automation system

The unprecedented depth of integration of B&R's vision system opens up new possibilities that go far beyond quality inspection. Information can be fed into control loops in real time to provide advanced machine control. This allows deterministic system behavior that leads to minimum machine downtimes and in the end a maximum OEE. Central data management enables detailed diagnostics and easy maintenance.

- Central data management in real time

- Easy diagnostics and maintenance

- Automatic firmware and parameter updates when the machine starts

- Minimized machine downtime

NETWORK INTEGRATION

Synchronization with µs precision

Both the hardware and software in B&R's vision solution are fully integrated in the control system. This is the only way to achieve absolute precision and microsecond synchronization between all automation components, including machine vision. The system can be connected with an axis in just a few clicks.

- Reproducible images for reproducible results

- Minimum FOV (field of view) necessary

- Razor-sharp images at high speed

TOOL INTEGRATION

Plug and run: From the office to the machine

With the B&R vision system, there's no more need for additional settings on the machine. It's plug and run. Usually, after a project is finalized in an engineering tool, developers have to adjust all settings directly on the machine in a second step. B&R calibrates vision systems, including all lighting elements, prior to delivery. This allows developers to test and verify their application at any time and from any location, without having to be physically present at the real machine.

- Faster development time

- Reduced development risk

- Easy maintenance and remote management

- Easy proof of concept for faster time-to-market

Simulation of image processing in Automation Studio

Getting a vision system up and running doesn't require complex programming skills. Engineers can easily program, parameterize and even simulate image processing in the Automation Studio engineering tool even without having to compile the entire project. Additionally, the ability to export test results to Excel helps to optimize the process and generate quality related data such as standard deviation.

- Common environment for engineers

- Programming and parametrization as an integral part of automation project

- Easy POC (proof of concept) for shorter time-to-market

- Machines operate more reliably

OCR without training or parametrization

The integrated character recognition function has an exceptional capability to instantly recognize characters. There’s no training or parametrization necessary to enable high-speed reading even with poor image quality or difficult characters, such as dot matrix fonts. A deep learning algorithm makes the function even more reliable and opens up exciting new ways to improve quality, boost productivity and prevent rejects - all while making manufacturing more flexible. All available smart camera features can be combined with deep OCR.

- World class performance of 26 TOPS

- High-speed reading also for poor quality

- Recognize even difficult characters instantly

- No more parameters than ROI and confidence level

- Deep OCR for better results

Global context anomaly detection

Deep learning-based anomaly detection identifies even the smallest deviations in structure with high reliability. This detection technology has already been successfully tested for automatic quality control of wooden surfaces, textiles, welding joints and more.

Unlike other deep learning methods, it requires no dedicated labelling of different defect classes. In most cases, around 100 good images are sufficient to train the network. During inference, anomaly detection segments the regions of the images that differ significantly from the training images.

- Clearly highlighted surface defects in a heatmap

- Quality relevance can be finely adjusted with downstream rule-based algorithms

- Boost machine performance without AI experts

- Higher productivity and quality along with less scrap

Plug and play for series-built machines or in case of service

B&R calibrates all lighting elements and optical systems – consisting of lens, sensor and focus adjustment – prior to delivery. As a result, there are no parameter or programming changes required when devices are exchanged in the field.

The system behaves in the same way every day - no matter if you install the camera yesterday, today, or tomorrow. In case of any service, the machine down times are reduced to a minimum. This also accelerates commissioning times for series-built machines.

- Minimum machine downtime in case of service

- Increased OEE

- Extremely high precision

- Reduced TCO

Single Wire Daisy Chain image pocessing with fieldbus connection

A Single Wire Daisy Chain connection enables fast cost-efficient wiring for B&R’s vision system. Cable lengths are minimized without requiring additional space in the control cabinet. During maintenance, there's no need for an additional trigger line.

The camera only needs one cable. An M12 hybrid connection integrates the camera into the machine network while ensuring a 24 VDC power supply. A second hybrid connection enables easy Daisy-Chain wiring with the lighting system.

- Cost-effective and organized wiring

- Minimal cable lengths without added cabinet space

- No need for extra trigger lines during maintenance

- Single cable for networking and power supply

Both the hardware and software of B&R's vision solution are fully integrated in the control system. This is the only way to achieve absolute precision and microsecond synchronization between all automation components – including machine vision. With only one engineering tool and one application to manage, controls engineers will now be able to implement many machine vision tasks on their own.