Students: Thomas Mayr, David Muster

Supervisor: Franz Wimmer

School: HTBLA Wels

Project name: Additive manufacturing – TriPod

Project presentation

Project presentation

The project concept

The project concept

How did the project come about?

The TriPod has been part of our equipment at HTBLA Wels for a long time. Other students have even used it for their graduation projects. It hasn't been used much in recent years, however, and we wanted to breathe new life into it. So, we decided to make the TriPod transportable and to convert it into a 3D printer. To do that, we needed to add two extruders and a heating plate. Our other goal was to update the TriPod to meet the latest safety requirements.

Challenges

Challenges

What was particularly unique, difficult or challenging about your project?

Special challenges for us were transferring the CNC code via USB to the PLC, adapting the G-code interpreter and implementing the HMI application.

Solution

Solution

What is your proposed solution and how do you plan to implement it?

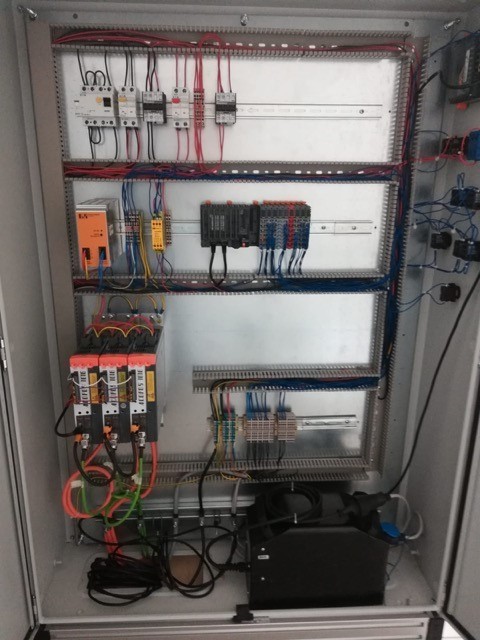

Our goal was to make the TriPod work and comply with the standards. We built a control cabinet, improved the existing program and added an extruder and heating plate. We also wanted to make the program transferable via USB and install the appropriate safety devices. A practical substructure for transporting the TriPod was also important to us and it was important to us that it had an appealing user interface.

|  |

Hardware used

Hardware used

Which B&R hardware is used?

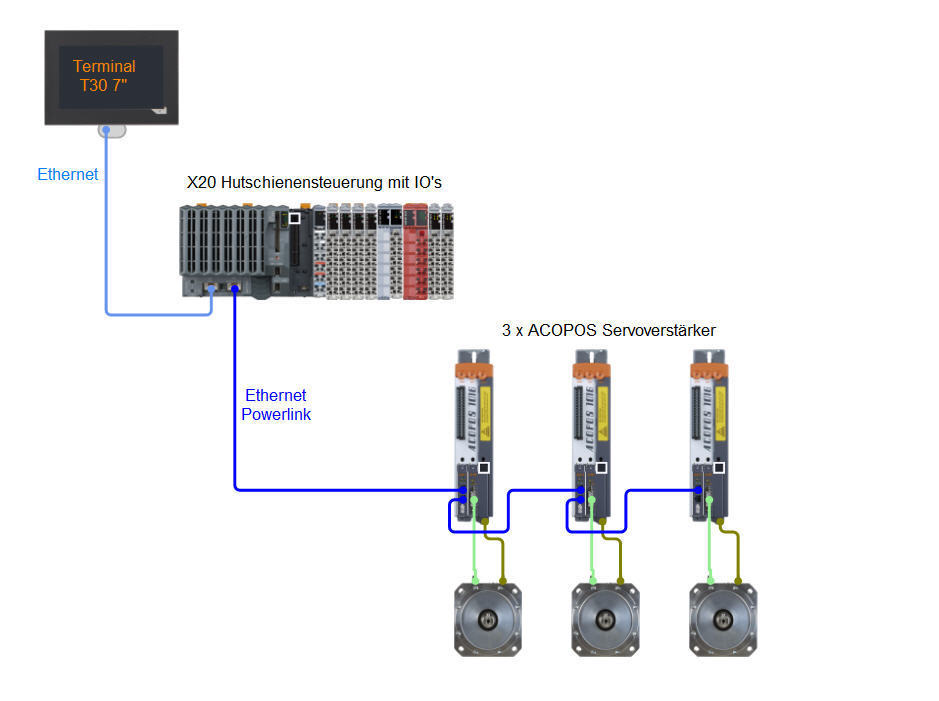

- PLC: X20CP1584

- Servo drives: 3x ACOPOS 1016 8V1016.50-2 with B&R servo motors

- Several digital and analog input/output modules

- HMI: Power Panel T70 7" 6PPT30.0702-20B

- Power supply: PS 1100 0PS1100.1