While they may be taken for granted by guests, a hotel's laundry facilities are a core element of daily operations. It's crucial that they stay up and running while occupying as little of the busy staff's time as possible. As one of the United States' largest manufacturers of industrial laundry systems, Ellis recognized the importance of comprehensive diagnostics and preventive maintenance accountability. Together with B&R, they developed their next-generation Side Loading Washer Extractor and Whisper Dryer with a focus on increasing uptime.

It is a sticky summer day , and the laundry staff at a local hotel is under pressure to keep their machines running and guests supplied with fresh linens. As is the case in most lean facilities, operators need clear direction for troubleshooting and real accountability to keep their equipment properly maintained and in prime condition.

When the hotel staff needs to get a machine back up and running, simply having a fault number or a one-line description is woefully insufficient. With this in mind, industrial laundry system manufacturer Ellis began asking its customers: "How can the machines better assist operators and facility maintenance personnel?"

Rising to the challenge

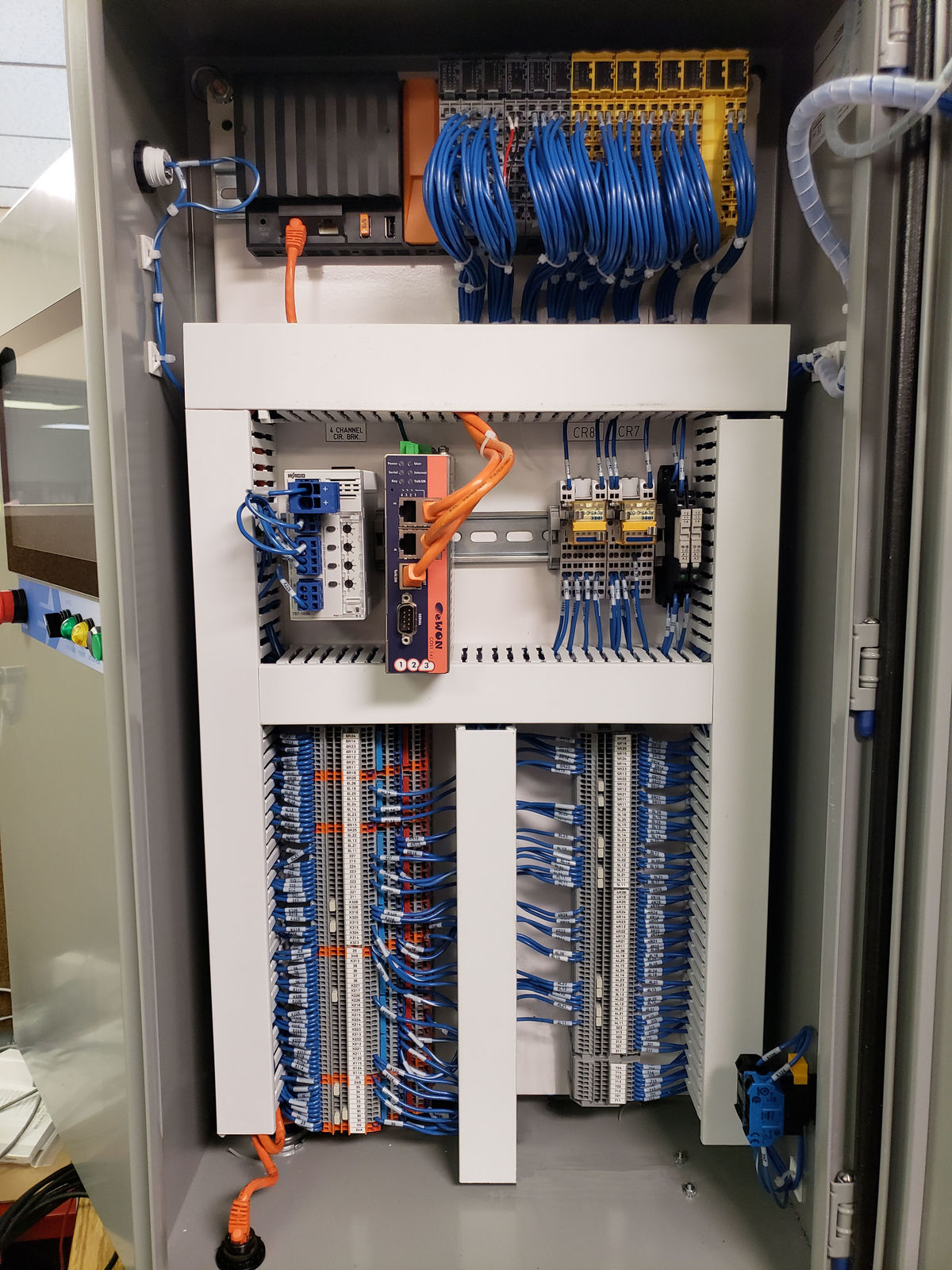

The feedback was clear: Operators need to know not only what the problem is, but how to resolve it, step by step. When Ellis saw the advanced functionality available in B&R's mapp View HMI solution – like the ability to embed videos and display PDF schematics – they knew they were on the right track. Ellis ended up with a multi-tier diagnostic solution that shows a picture of where the problem is occurring on the machine or in the electrical cabinet. Where applicable, it also shows a video on how to resolve the issue and a schematic layout.

Another challenge, especially for smaller facilities, is that managers take the machine manual and its preventive maintenance schedule and place it on the shelf in their office, never to open it again. This does a huge disservice to such a critical asset.

To help, Ellis incorporated the preventive maintenance schedule into its machine control system, basing it on actual runtime hours. When a preventive maintenance notice appears, a facility engineer must log in with their employee ID number and sign off that the maintenance has been performed. This accountability ensures the equipment is properly maintained and continues to run at peak performance.

Designed for performance, built for dependability

The fresh-smelling sheets on your hotel bed and the pristine white tablecloth on your table at the luxury restaurant would not be the same without Ellis laundry equipment. Based outside Chicago in Itasca Illinois, Ellis has flourished for over 120 years by building market-leading industrial washers and dryers. Using B&R enables Ellis to combine the industry's highest level of safety technology with a streamlined approach to HMI and diagnostics.

When Ellis designed its Side Loading Washer Extractor, safety was a top priority. B&R's integrated safety technology also provides a much more intuitive and helpful set of diagnostic tools than with traditional hardwired relays, such as overcurrent faults or swapped wiring terminations. This makes it easier to commission machines on the floor and helps customers perform troubleshooting in the field.

For Ellis, B&R is more than just a technology partner. CEO and Chairman Bob Fesmire Sr. and President Bob Fesmire Jr. call B&R "instrumental in providing additional resources, ideas and solutions," noting that B&R's engineering support team, which is made up of highly knowledgeable and trained engineers, offers access to resources that quicken product improvements as well as development. "They have given our company the flexibility we need to continually meet our core value: servicing the customer."

Reliable, efficient and safe

From its roots in 1898 as a manufacturer of standalone laundry machines, Ellis has evolved to become a plant automation provider, moving laundry between machines and processes. Ellis has also expanded their Water Solution product offering to include recycling filtration equipment. Today, they are one of the largest manufacturers of industrial laundry systems in the United States. As the marketplace pressures their customers to reduce labor dollars and maintain uptime, Ellis provides effective new solutions to meet these goals.

The outlook for Ellis is a promising one. They will continue to expand B&R machine controls to their next generation of equipment, using a framework consistent with the washer extractors so they will have the same look and feel. In the future, Ellis' Water Solutions division will also be offering microfiltration and ultrafiltration technologies that will benefit from B&R's predictive maintenance capabilities.

| Bob Fesmire Jr. President, Ellis Corp. "B&R has given our company the flexibility we need to continually meet our core value: servicing the customer." |