Future of packaging

As a machine builder, you are forced to adapt to a market that is changing dramatically as we speak. It is vital to increase your resilience. What manufacturers want to know is: How do you efficiently handle shorter product lifecycles and cater to the growing demand for highly personalized production? And how do you stay competitive by reducing production costs and machine footprint?

This is where B&R enters the picture. At interpack 2023, B&R's packaging specialist Wlady Martino and his team demonstrated the future of packaging. On our booth (Hall 06, Booth E62), visitors got a personal introduction to our latest technologies in action.

But that's not all: Adaptive solutions powered by B&R technology were available in a variety of industry applications all across the interpack fairgrounds. A personalized adaptive interpack tour was the highlight for just the right inspiration.

Live at interpack

That was interpack 2023: Get some impressions of our time at the trade fair and discover our booth. Let Wlady Martino, Global Segment Manager Packaging, take you on a tour through our booth. There's a lot to discover.

Understand adaptive manufacturing

Success in today's markets demands a fundamental shift in thinking to offer consumers the personalized experience they demand.

- Adaptive manufacturing delivers

- On-the-fly changeover at the touch of a button

- Readiness for unforeseen future products

- Profitable personalization down to batch-size-one

- High performance on a small footprint

Adaptive interpack tour

To implement direct-to-consumer and omnichannel strategies and make small-batch production profitable, producers rely on their OEM suppliers for innovative solutions. All over the interpack fairgrounds, impressive demonstrations of how machine builders are boosting overall equipment effectiveness and shrinking their machine footprint with adaptive automation solutions from B&R were there to be explored. A variety of different industries offered the perfect inspiration for future projects.

B&R booth

1. B&R portfolio

#ThisIsAutomation wall

As ABB's machine automation division, B&R offers the broadest automation portfolio on the market and the right solution for every industry.

- Seamless coordination between B&R products gives machine builders a competitive edge in performance and quality.

- The B&R software ecosystem offers a powerful combination of integration and open standards that unlocks exciting possibilities.

#ThinkAdaptive wall

B&R enables adaptive manufacturing through track-based and planar product transport systems combined with robotics, machine vision and digital twins and controlled with our core automation platform.

- Success in today's markets demands a fundamental shift in thinking to offer consumers the person-alized experience they demand.

- Adaptive manufacturing delivers: On-the-fly changeover at the touch of a button (OEE) , readiness for unforeseen future products (TTM), profitable personalization down to batch-size-one (ROI), high performance on a small footprint (ROI)

2. Adaptive manufacturing demo

Experience the power of adaptability: Made possible by two loops of ACOPOStrak, two vision systems, a Codian delta robot and digital twin simulation.

- High-speed inspection & sorting

- Products switch tracks on the fly

- Robot tracking at full speed

- Hot swapping & vision scanning

- Codian robot exchanges shuttles on pit lane

- Mileage tracking & predictive maintenance

- Dynamic grouping & rainbow packaging

- Fully customized processing for each and every item on the line

- Package any combination with no downtime & no mechanical setup

3. ACOPOS 6D demo

Let's put the shuttles to work – and then let them play. See how ACOPOS 6D's independent floating shuttles handle packaging processes like filling, capping and labeling. Then watch them dance in formation, pose for the camera, and even get a spa treatment in the washdown area.

- Process flow

- Shuttle-as-a-scale weighing for identification & quality control

- Washdown protection & anti-sloshing

- Dynamic in-process personalization & sorting

- Live digital twin simulation

- System features

- Choreography in six degrees of freedom

- ACOPOS 6D + Machine vision

- Washdown protection

4. KAO machine: Personalized cosmetics

This new machine from KAO creates decorative images out of foundation powder by moving each case on independent ACOPOS 6D shuttles below a stationary nozzle. The combination of absolute freedom and fine precision allow KAO to make each powder case a unique work of art.

"With this solution, we are accelerating the shift to personalized marketing in cosmetics." – KAO

5. Software & Co-creation

At co-creation labs around the world, B&R builds bridges between research, development and applications to transform the latest advancements in automation into competitive advantage for its customers.

- Reduce development risk

- Accelerate your project through evaluation, execution and validation

- Test cutting-edge automation and leverage B&R expertise

Plan your adaptive tour

FUJI SEAL

Agile Line

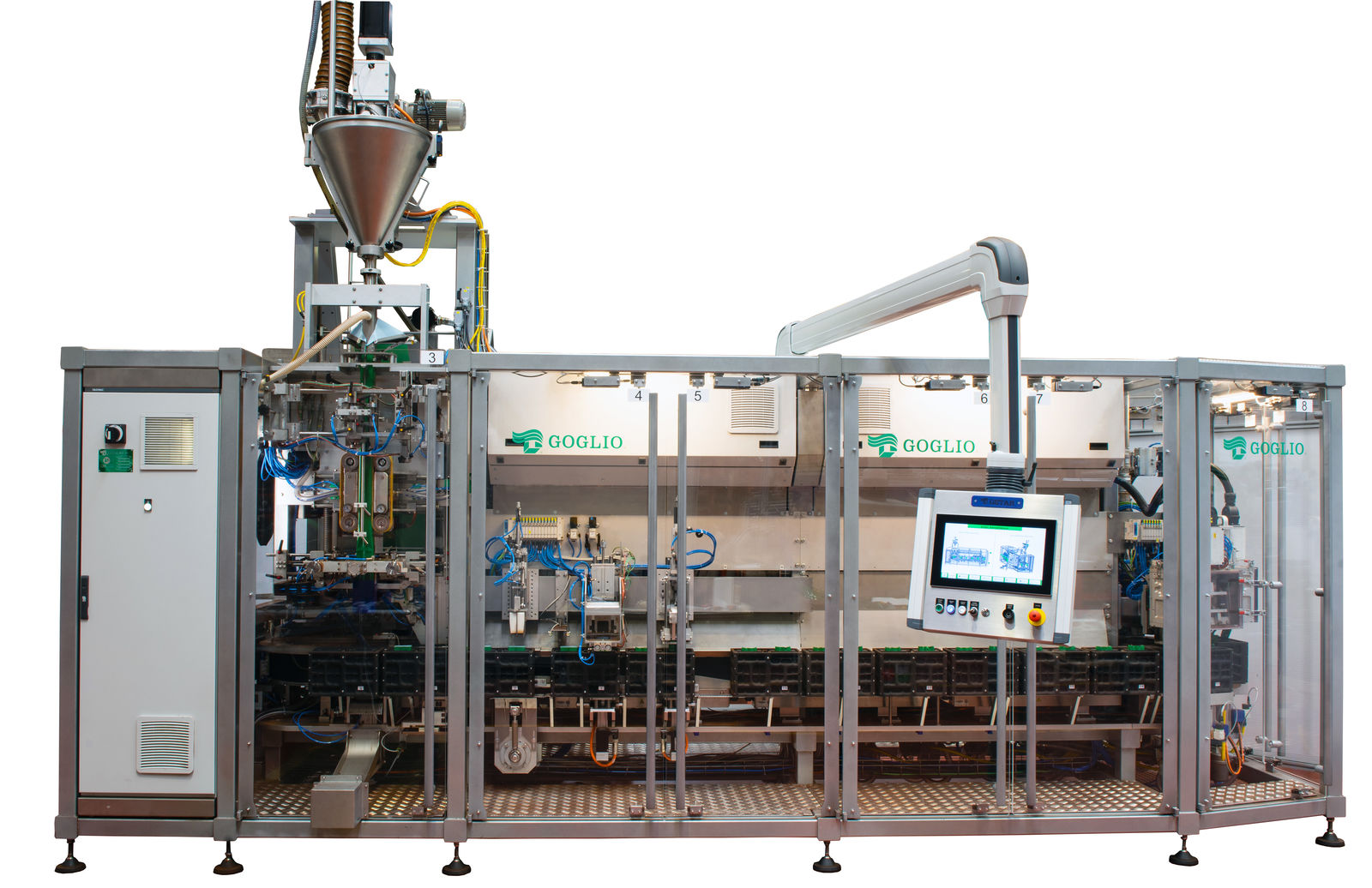

GOGLIO

G STAR

HDG PACKAGING MACHINES

FLX-Track

IMA COFFEE

Synkro

IMA ILAPAK

Doytronic 120

KAO COSMETICS

Line Art

MAKRO LABELLING

C-Line

OPTIMA PACKAGING GROUP

OPTIMA CFL - OPTIMA CBF

PFM PACKAGING MACHINERY

D400 EPT

R.A JONES

Criterion CLI-100

SARONG

Magneta

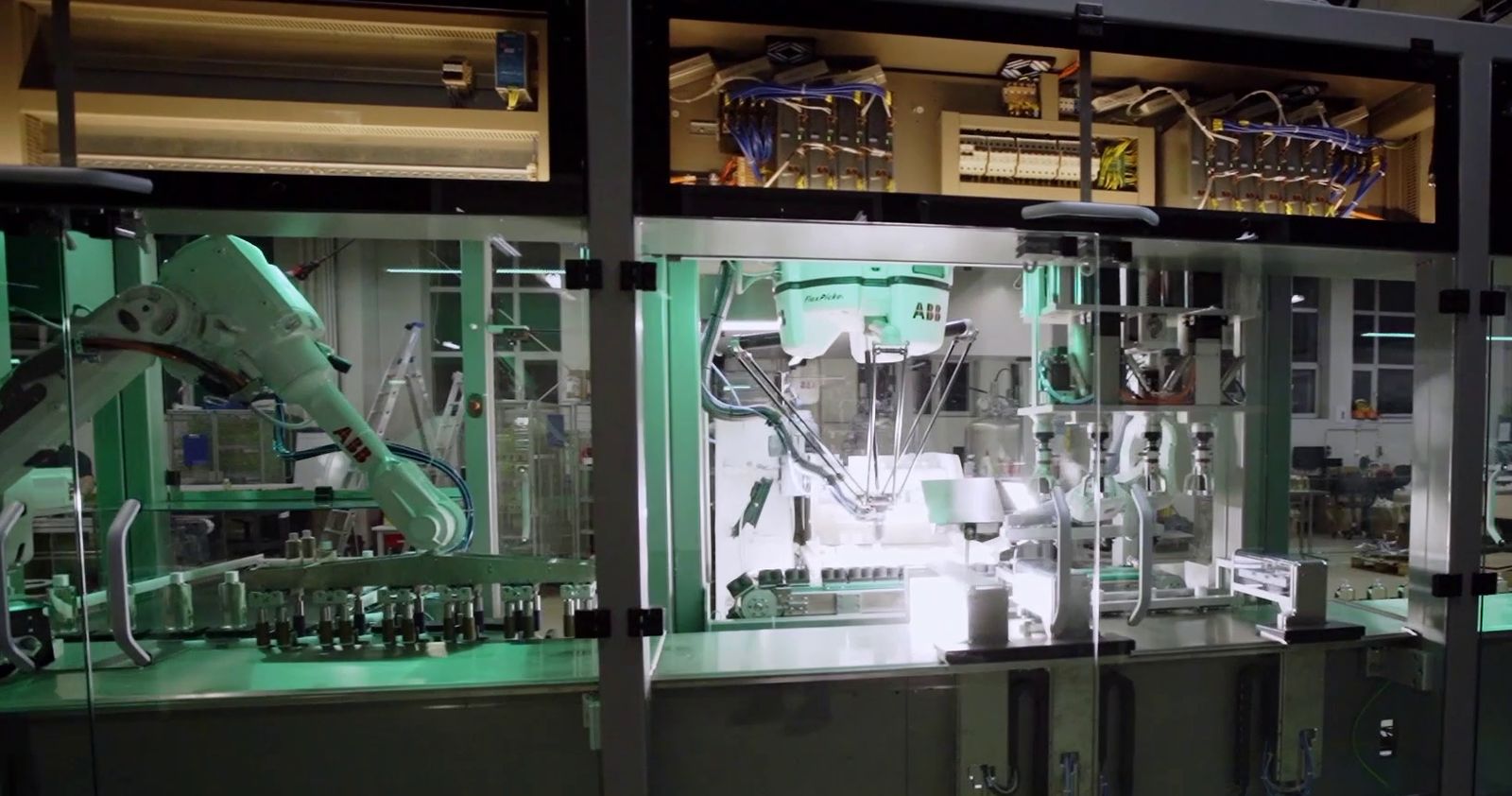

U2 ROBOTICS - UNILOGO

Cleanline

Hall 15, booth C02

- Filling-capping-labelling line

- ACOPOStrak vertical | ABB robotics | full B&R

WOLF PACKAGING MACHINES