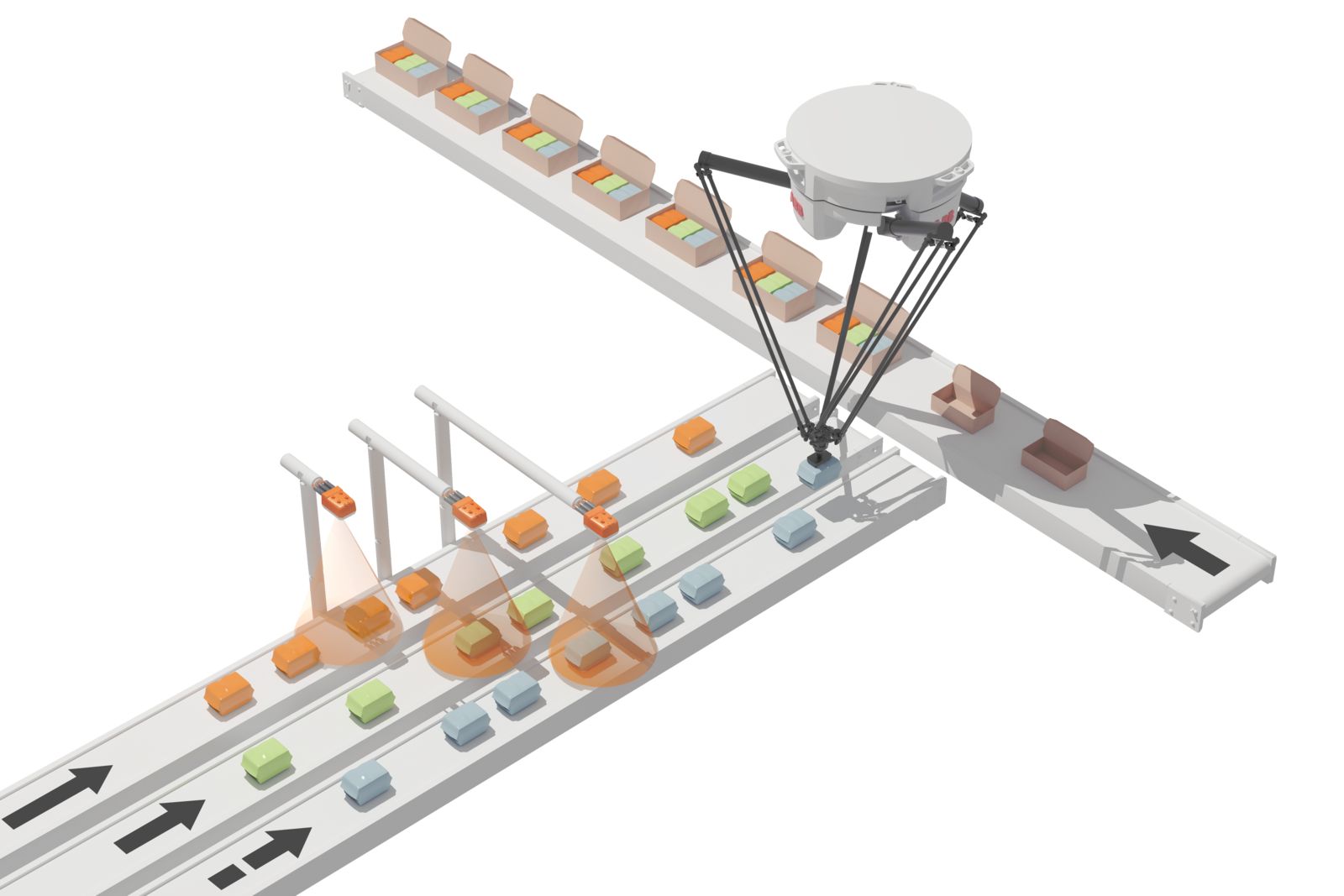

High-precision pick-and-place applications can make production lines more productive and more reliable. Until now, however, pick-and-place robots have been operated as separate units from the machine itself, which places an upper limit on how productive they can be. With the complete integration of robotics control into its automation system and introduction of a new software solution, B&R is now changing that.

"Pick-and-place applications have one very big advantage," explains B&R's product manger for integrated robotics, Sebastian Brandstetter. "The robots perform the same exact movement over and over, 24 hours a day, with a constant level of precision." What does that mean for the machine operator?

- More efficiency

- Reduced waste

- Less fatigue

Fewer errors

"Many of the classic pick-and-place activities have already been automated," notes Brandstetter. Still, there remain countless manual stations where human workers perform monotonous tasks like placing products into boxes or sorting out defective items. This has two major disadvantages: First, it's becoming increasingly difficult to find people willing to do this work, and second, the monotonous nature means it's only a matter of time until mistakes are made. That's why pick-and-place solutions are such a perfect fit in these cases.

"However," adds Brandstetter, "implementing a pick-and-place system is more complex than you might think." Simply programming the robot kinematics is not enough. There are many other important factors that the application must take into consideration:

- The movements of each robot

- Coordination between robots and conveyors

- Coordination with a machine vision system

- The machine process itself

Logistical challenge

"When it comes down to it, pick-and-place is basically a matter of logistics," says Brandstetter. You need to transport things from A to B as efficiently as possible. Simple as that may sound, it relies on some very complex calculations and corresponding programming.

"That's exactly why we've added a special new component to our mapp Technology solution," says Brandstetter. To set up an application, all that's left to do is describe the desired process. That can be as easy as "Take all the orange products and put them in the first box." The intelligent mapp component handles the rest.

Intelligent software modules

"To make that possible, we programmed many different software modules, which get linked together automatically in the background to arrive at the desired result." The interface between them, known as a mapp Link, also connects them to any other mapp components that are used, such as mapp Vision for machine vision, mapp Robotics for robotics control or mapp Axis for single-axis motion control.

"The great advantage of mapp Technology is that all the components communicate with each other automatically," says Brandstetter. Since the user doesn't have to program a single line of code, they have more time to focus on their primary challenge: optimizing the machine process itself.

To continue the example with the orange products, mapp Pick&Place would work like this:

- A machine vision camera detects an orange product

- Its position is sent to the robot in real time via the mapp Link

- mapp Robotics calculates the optimal path

- The robot picks up the product and places it into the box

Configuration instead of programming

"This basic concept also scales to much more complex applications," notes Brandstetter. The box might be moving along a conveyor belt, or the products might be placed into the box in a specific arrangement. "Even in more advanced cases like those, the same principle applies: the person creating the application is only configuring the functions they want – there's no programming involved."

mapp Pick&Place is so flexible, it also works in conjunction with intelligent track systems like ACOPOStrak. Not only that, but there's no limit to how many robots can be used in the application. Especially in high-speed sorting applications, it's often helpful to have a series of robots to maximize output. In addition to delta robots, it's also possible to use articulated arm or SCARA robots.

The choice is up to the user

"There are a variety of possible logistical strategies for solving pick-and-place tasks," explains Brandstetter. "And we took those into consideration when creating mapp Pick&Place." The user can choose between a variety of strategies, such as:

- First in, first out (FIFO)

- Prioritization of certain tasks or products

- Fastest possible pick duration

- Energy-saving movement profiles

- Movement profiles to minimize mechanical wear

These options allow the process to be optimized for any possible situation. By simplifying implementation of robotics and pick-and-place operations, mapp Pick&Place drastically lowers the investment risk involved in incorporating robots into machine processes. The precise synchronization between the robots and the rest of the machine also brings a considerable boost in productivity.

B&R is the world's only single-source supplier for controls and robotics. Robots from its parent company ABB are fully integrated in the B&R automation system. Customers benefit from unprecedented precision in synchronization between robotics and machine control. They need only one controller and one engineering system for development, diagnostics and maintenance.