Simple and fast production with ACOPOStrak

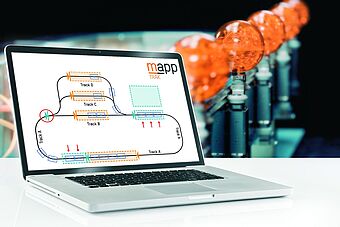

The mapp Trak system software from B&R makes intelligent transport systems easy to work with. It facilitates engineering and optimizes time to market for new products. The software is based on process-oriented programming and features integrated simulation.

mapp Trak ensures that the shuttles do not collide, cross virtual barriers or violate configurable speed limits. FDA-compliant tracking is also easy to implement with mapp Trak. The software links the product data with the respective shuttles and thus makes the entire manufacturing process completely traceable.

Process-oriented programming

With mapp Trak, the track system application is created using process-oriented programming. The software engineer simply defines rules for how the shuttles should behave on the track. The rules become active when shuttles pass virtual trigger points. The makes implementation of motion sequences more efficient and drastically reduces the amount of programming required for the individual shuttles.

Simulation for efficient operation

With the integrated simulation options in mapp Trak, the developer can run tests to identify the optimum number and speed of shuttles to maximize productivity. The same system software is used in both the simulation and the real plant, which makes it possible to switch between simulation and real operation at any time. How the shuttles interact with additional mechanical elements such as robots can be visualized with B&R Scene Viewer.