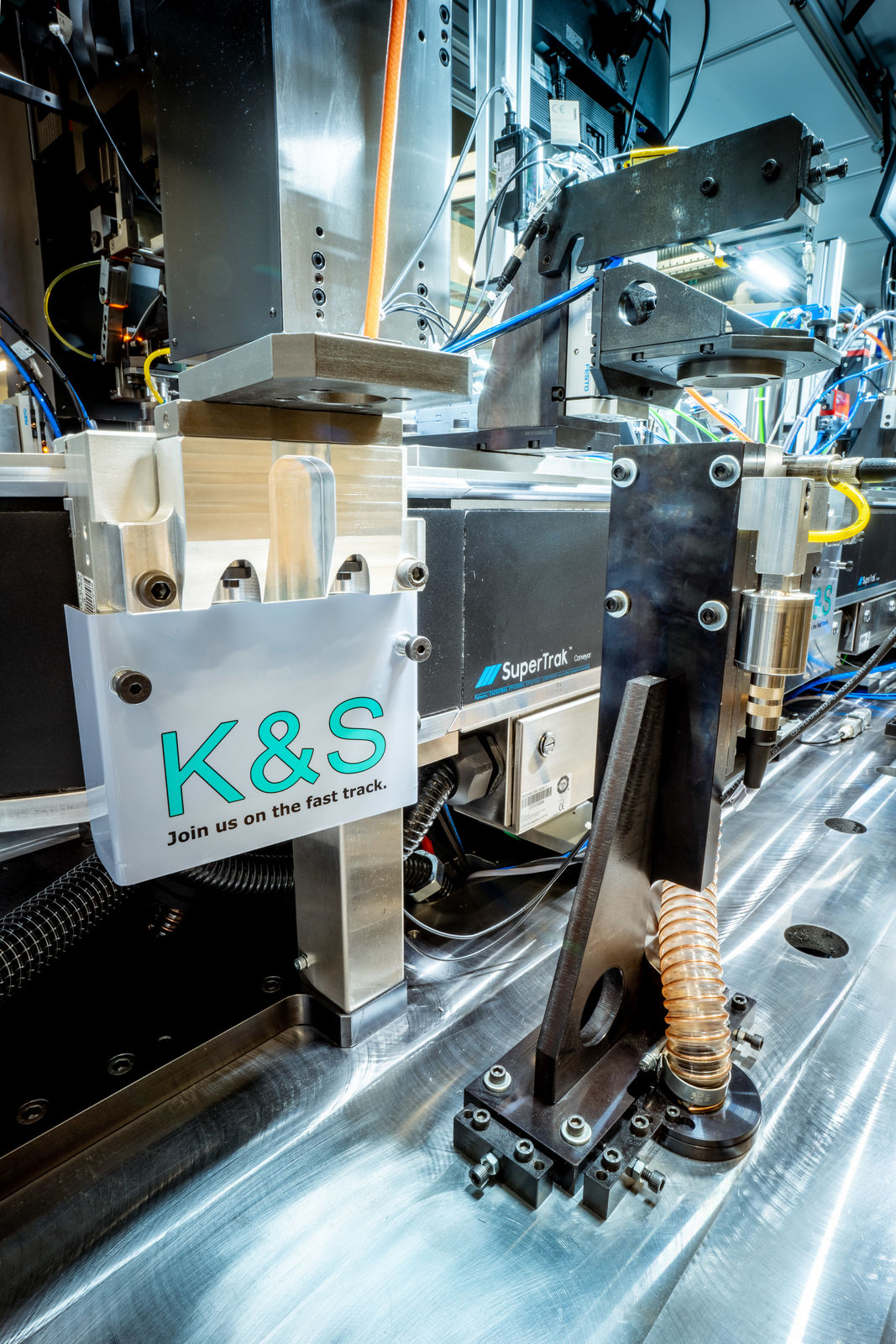

Maximum flexibility: a quality that manufacturers are requesting with increasingly high-priority from their OEM suppliers. Plants where products are moved with rigid timing between coupled subsystems do not provide this flexibility, whereas independently controlled workpiece carriers (WPC) can make all the difference. The added flexibility can bring enormous benefits for both manufacturers and their OEM suppliers. That's what plant builder K&S has proven with its new assembly machine featuring B&R's long-stator linear motor transport system, SuperTrak.

Shortly before an already completed assembly line was scheduled for delivery, K&S sales colleagues Michael Fritsch and Simone Schuster received a phone call informing them of an urgent change: the system would need to produce a second variant of the medical technology component it had been designed and built for.

Flexibility is the key

Last-minute changes like this come with the territory, says Fritsch: "We design solutions that are tailored to each customer's needs. Those needs can change unexpectedly, however, since the products being assembled are entirely new. We start designing the machine at a time when there are still a lot of unknowns about the product's final specifications." K&S has to be prepared to adapt to changes throughout the entire project and beyond.

K&S first opened its doors in 1990 as a tool manufacturer. As changing requirements called for more flexibility, the company expanded its focus and now offers complete packages for automation. The portfolio includes a wide range of system modules for punching, bending, assembling, welding and soldering. The modules are designed to be used in rigidly timed circular and linear production lines with output quantities up to 100 million units per year. K&S has also developed high-speed feeding solutions and tape-and-reel packaging machines.

"We've created them as standardized modules, so they can be easily rearranged to add or remove process steps," explains Fritsch.

The rigid timing of the conventional workpiece carrier systems widely used in production and assembly lines limits the potential for flexibility. In these systems, the maximum output is always determined by the slowest processing station. If the second stage of expansion requires a higher. all process stations must be created twice so that two parts can be processed at the same time. This is also the case for stations that could easily achieve a higher throughput within the system cycle time. In such cases, independently controlled workpiece carriers driven by long-stator linear motors open up new dimensions of system flexibility for plant builders and their customers.

Higher flexibility with SuperTrak

When the above-mentioned medical technology producer turned to K&S for an assembly line to produce a new flow component, K&S began the search for an optimal solution. To gain the freedom to send workpiece carriers to different processing stations as needed, K&S decided to use the independently controlled shuttles of B&R's long-stator linear motor based SuperTrak transport system.

"The customer was clear that they wanted a state-of-the-art assembly line that would stand up to future challenges," recalls Schuster. "But when we started, we still had no idea what specific variants it would need to assemble." Nor did they know what specific demands the assembly and quality assurance processes would place on the machine. Since it was a new product, it was also unclear what quantities would be needed.

No pre-production required

K&S designed the system to be released in two stages. The first stage would be designed to fill the predicted market demand, with the option to upgrade to twice the output. "Producers would typically use a pre-production assembly in such cases, but that's not necessary anymore," notes Fritsch.

K&S used a closed, oval-shaped track consisting of two 180-degree curved segments and eight straight segments (1 meter each) from B&R’s SuperTrak system, mounted on a stable, 6-meter long machine base. This setup offers enough space for about 20 standard modules from K&S. In the first-stage variant, 14 of those stations are occupied.

Integrated collision avoidance

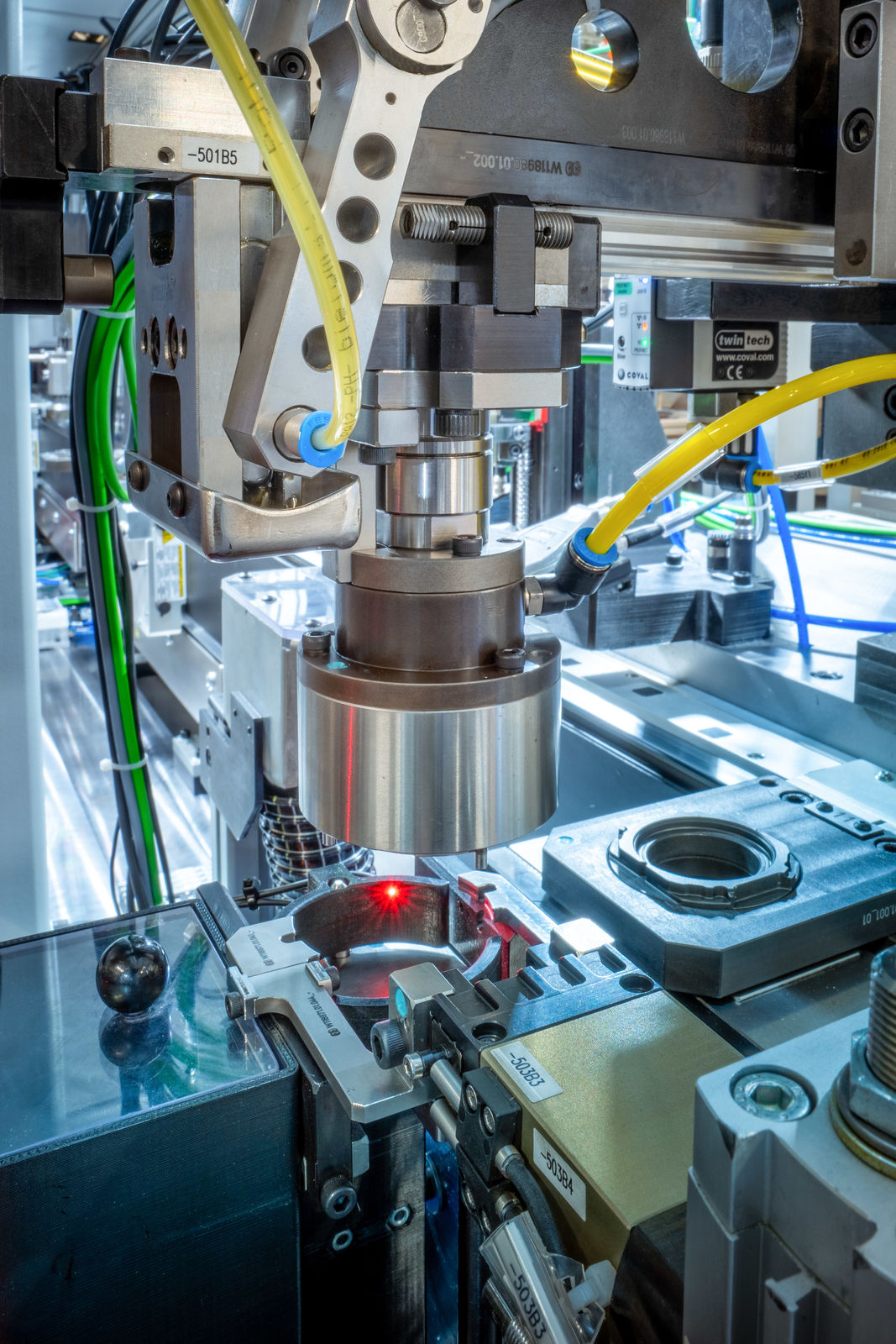

Shuttles holding custom workpiece carriers are guided through processing stations located around the oval-shaped track. The values for direction, acceleration, speed and target position can be programmed individually for each shuttle. Integrated collision avoidance prevents the shuttles from direct contact with each other and ensures automatic and safe queuing in front of the process stations.

It's possible to skip certain processing stations, stop at additional stations or move to multiple positions within a given station to produce a different product variant or expand the system with minimal effort. This gives the customer the advantage of being able to adjust output over the first few phases of the product lifecycle.

Higher output with hardly any work

SuperTrak brings the customer even more savings when they chose to increase the output of their system. In many applications, it's only a small number of stations that are really time critical. SuperTrak makes it easy to boost output in a quick and cost-effective way simply by doubling up these time-critical stations and adding a few more shuttles.

Machine builders also benefit from SuperTrak's flexibility. If they plan in sufficient extra space, they're able to make any changes that become necessary throughout any stage of the project with relatively little effort. "That really payed off when we received that last minute request to equip the line for an additional product," recalls the K&S team. All that was needed were a few more shuttles and an additional processing station.

Quality assurance at its best

K&S took advantage of the flexibility offered by the independently controlled shuttles to boost the availability of the assembly line. For quality assurance, the inspection stations are checked regularly using special dummy workpieces. In systems with rigidly linked workpiece carriers, an operator usually has to perform this step manually. That means disrupting the entire production process, so it is done as infrequently as possible.

With SuperTrak, the dummies are software-controlled – they're automatically added to the carriers at a pick-and-place station and then transported to the processing station to be tested. Once the test has been completed, the dummy is taken back to the pick-and-place station and removed from the line. Without the need for manual intervention, the system is more available. Since the automated tests using SuperTrak have so little impact on productivity, they can be performed more frequently – and that increases process reliability.

On top of that, faulty workpieces are prevented from causing downstream damage. They are sent directly from the testing station to the removal station without stopping at any assembly stations along the way.

B&R as a reliable partner

"Due to their numerous advantages, we have used long-stator linear motor systems to transport workpiece carriers in other lines before. Yet, this medical equipment assembly line is the first time we've used such a system from B&R," says Fritsch. One reason K&S decided on B&R was the availability of two long-stator linear motor systems, SuperTrak and ACOPOStrak. The B&R portfolio also makes it easy to create perfectly orchestrated complete solutions where it's possible to do things like synchronize other motion control axes with the shuttle movements. All in all, K&S enjoys new dimensions in design freedom and can respond to its customers' needs with much more flexibility.

Author: Franz Rossmann, technology journalist from near Munich

| Simone Schuster and Michael Fritsch Sales Team, K&S Anlagenbau GmbH "Independent control of workpiece transport implemented with B&R's long-stator linear motor solution allows us to respond with much more flexibility as our customers' needs evolve over the entire lifecycle of a system." |