10 years of integrated safety from B&R

In 2008, B&R unveiled its groundbreaking integrated safety technology. In the decade since, B&R has established itself among the world's preeminent manufacturers of programmable safety technology. Franz Kaufleitner, product manager for integrated safety technology at B&R, explains how his company went from newcomer to trendsetter in the safety industry.

Mr. Kaufleitner, when did B&R decide to begin developing safety technology?

B&R has always taken a holistic approach to system design, so incorporating safety functions into our automation portfolio was a natural progression. At the turn of the millennium, we had already equipped our ACOPOS servo drives with a purely electronic safe torque off function (STO) – a world first that has since been widely adopted throughout the industry. In 2004 came the decision to develop a full scope of integrated safety technology comprising controllers, a programming tool, safe I/O modules and safe drive functions. By the time the safety hype peaked around 2008, we were already able to offer our customers a comprehensive, fully integrated safety solution.

How is B&R safety technology different from other systems?

Safety technology should contribute to the overall automation performance, not be treated as a nuisance or an afterthought. While other safety systems are focused on stopping the machine, we're finding ways to keep production up and running. Our extensive library of safety functions allows users to respond flexibly to safety events. Our safe machine options enable our customers to manage a single safety application that covers the many variants of their modular machines. It's this vast potential of safety technology that has inspired us from the very beginning. There is so much more to safety than simply shutting down the machine.

How has B&R's safety portfolio changed over time?

We laid the foundation in 2008 with a safety controller and I/O modules featuring four safe digital inputs and four safe digital outputs. Ever since, we've been expanding the portfolio in two dimensions. On the one hand, we've introduced revolutionary new functions and products . There's SafeROBOTICS, which offers an extensive array of safety functions for kinematic chains, and DataToSafeDATA, which makes it possible to incorporate standard signals in safety functions. Today, B&R's safety portfolio includes more than 120 different products.

And the other dimension?

We have also been expanding in terms of conformity to meet the needs of different industries and applications. Having started with a focus on traditional machine building, we soon added products with IP67 protection, coated products for harsh environments, and products with newly established certifications, such as DNV GL for maritime and offshore applications. Our safety products can now also be found in wind turbines, theater and stage systems, elevators, plant and process automation systems, steel mills, logistics centers and much more.

When you talk about B&R safety technology, openSAFETY comes to mind – what's new on that front?

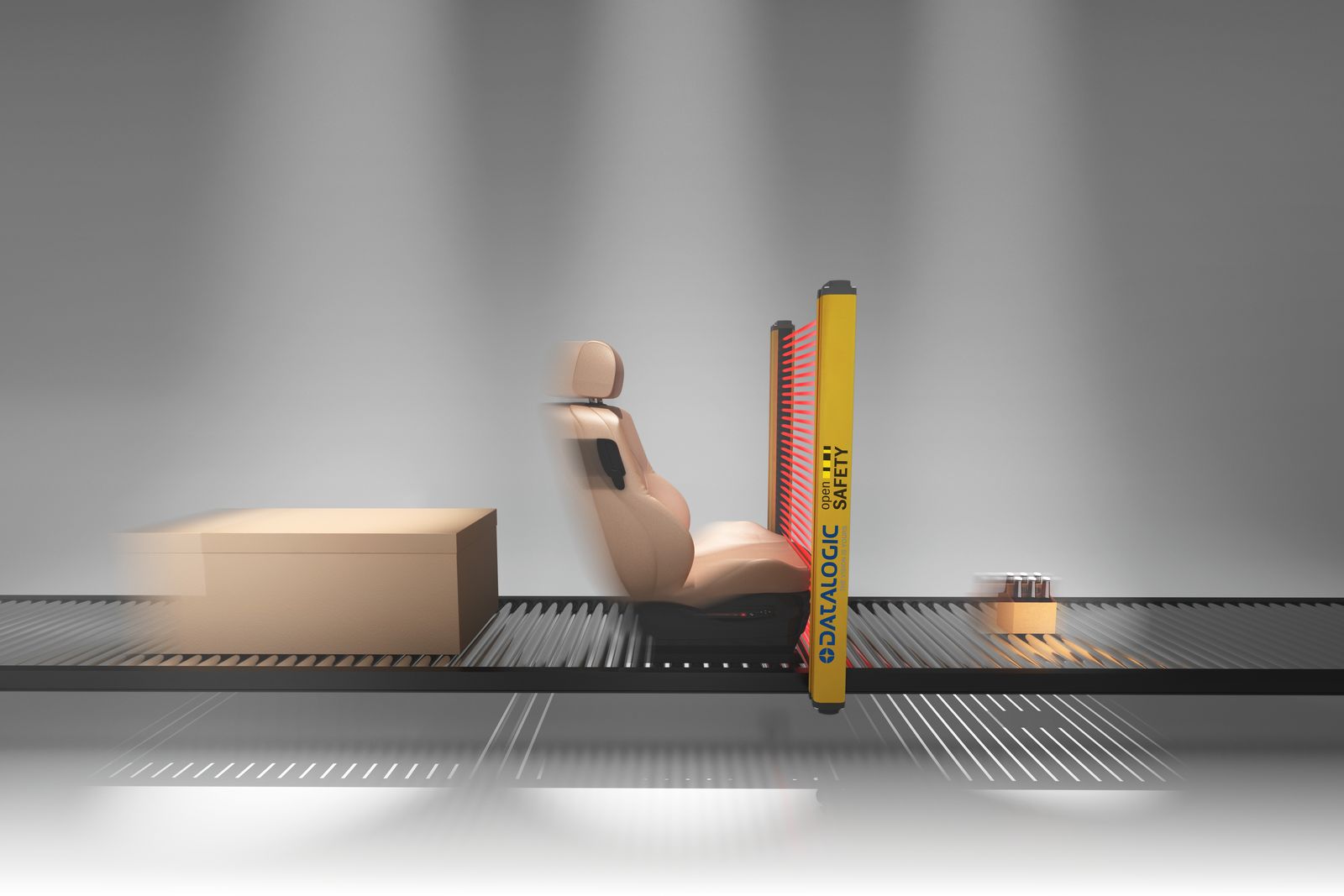

openSAFETY is among the three most successful safety protocols worldwide. As an open-source protocol, it has many applications with no direct ties to B&R. An exciting new one is the openSAFETY light curtain from Datalogic. It's a light curtain equipped with a POWERLINK/openSAFETY interface that can be directly integrated into a machine's bus system.

More about the openSAFETY light curtain

What lies ahead for B&R safety?

The two-dimensional growth will certainly continue. In terms of expanded functionality, we'll be incorporating integrated safety technology into the mapp Technology software framework. This will include out-of-the-box solutions for the safe machine options I mentioned. Since the mapp components talk to each other, the mapp safety functions will be networked with the components for user management, alarms and HMI – without the user ever having to program a single line of code. You can imagine it like this: Because it talks to the user management system, the HMI application knows whether the current user is authorized to switch operating modes, and only displays that option if they are. In terms of expanding the range of applications, the new X90 Safety will bring the benefits our integrated safety technology to mobile applications including agricultural equipment, municipal vehicles, excavators and cranes.

Whatever the technological frontier, our customers can rest assured that we will always lead the way. A decision for B&R safety technology is a decision for a long-lasting, future-proof solution. Over the last ten years, we have proven that safety technology has much more to offer than simply shutting down the machine, and we intend to continue exploring its enormous potential.

How B&R safety technology works

Video: B&R safety technology

| Franz Kaufleitner Product Manager - Integrated Safety Technology, B&R Over the last ten years, we have proven that programmable safety technology has much more to offer than simply shutting down the machine, and we intend to continue exploring its enormous potential. |