CHT R. BEITLICH's decentralized control system with isolated PDA had seen better days. Rather than helping to optimize production, it was tying up valuable resources. Changes to the system were tedious; replacement parts were getting harder and harder to come by. The company began surveying the market for an appropriate replacement. In the end, there was only one system that met all of their requirements.

"It was becoming increasingly apparent that our antiquated systems would soon no longer be able to keep up with the intensifying demands," says Günther Schätzle, head of production engineering at CHT R. BEITLICH. The requirements for product quality, quality assurance, process reliability and safety regulations had all changed dramatically over the years.

"What is more, our old technology was preventing us from filling new orders," adds Schätzle. It took three days, for example, just to install a new valve and get it up and running. On top of that, equipment was failing more and more frequently, and replacement parts were no longer readily available.

The control, HMI and data acquisition systems, which had become outdated, inflexible and prone to failure would need to be replaced with state-of-the-art new technology. "Fully automating everything was certainly not our primary goal," adds Schätzle, "as that would have been too complex for our multifunctional stations."

83 systems at 2 locations

CHT produces specialty chemicals in the areas of textiles, textile care, construction chemicals and performance chemicals. The company's customer-oriented product development continues to expand an already broad spectrum of products. The majority of the CHT's revenue comes from very complex products, which are produced primarily at the production and logistics centers in Dusslingen and Oyten, Germany.

These sites are home to hundreds of systems including higher-level supply systems and a variety of mixing vessels and chemical reactors. Many of the production stations are multifunctional and can produce up to 100 different products.

The APROL process control system stands out

CHT formed a team of experts to perform an in-depth evaluation of three different process control systems, as well as control and HMI solutions from two bidders, based on an exhaustive matrix of specific criteria. In the end, B&R came out on top.

"One of the decisive factors was that B&R's process control system – in contrast to other systems – provides optimum support for stepwise migration. APROL allowed us to move our production stations successively to the new process control system while keeping the old systems running in parallel."

Process control migration at 2 locations

Migration at the Dusslingen site began in the spring of 2011. From the beginning, there was an emphasis on creating standardized procedures that could be repeated at other locations. "It was very important to us that we arrive at standardized control procedures that are consistent at all of our locations, and that they're able to use the same code and the same hardware," says Schätzle. This preparation made the migration of the Oyten site, which began in early 2013, much faster and more cost-effective to implement.

Today, changes to the CHT libraries are applied simultaneously at both sites, which simplifies the validation process considerably. Via remote networks, programmers can access the controllers at the two locations from anywhere. While the Dusslingen site already has all the main systems integrated in the process control solution, Oyten is still working on migration of special-purpose systems, with the ultimate goal of controlling the entire plant with APROL.

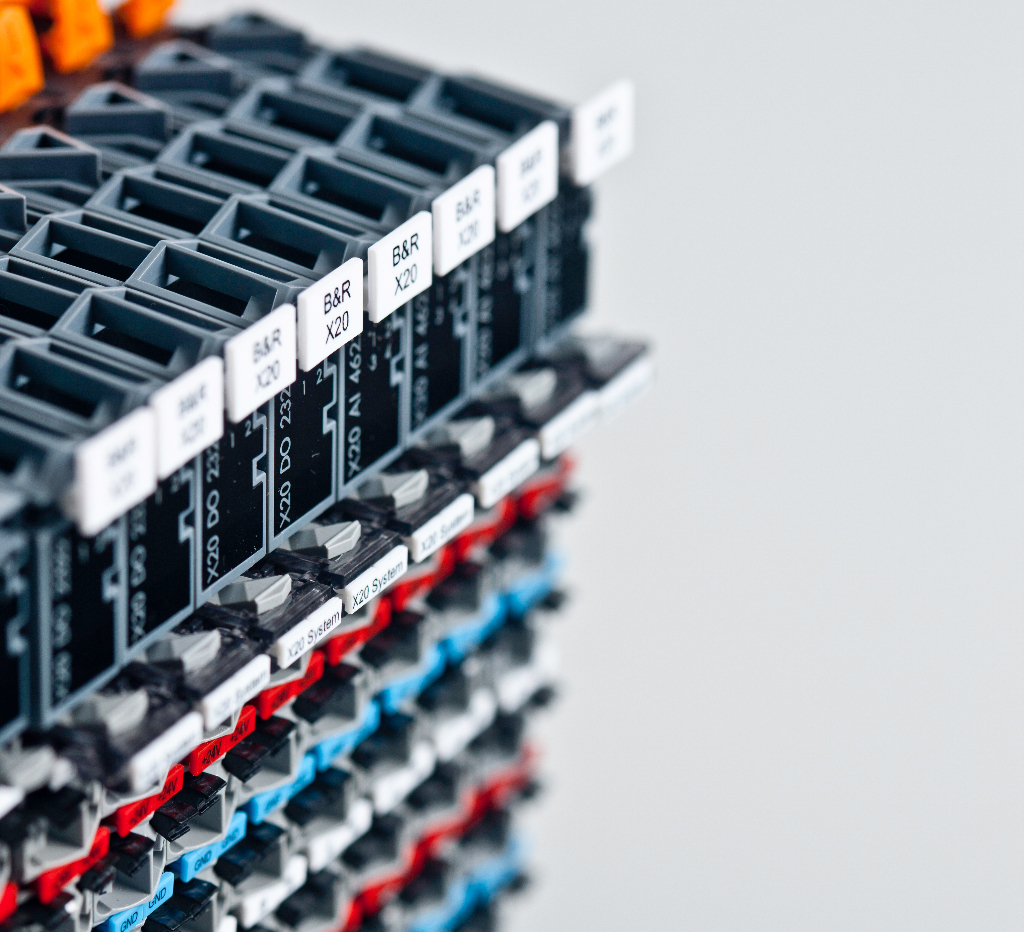

B&R hardware perfectly scaled to the system structure

B&R's finely graduated selection of control and HMI products has allowed CHT to match the performance of each system's PLC to its requirements, as well as equip each system with a unique lineup of I/O modules and its own HMI unit. It was this flexibility that led the chemical producer to rely on B&R for control and HMI in addition to the process control system.

"The advantage is that we can mirror the actual system structure directly in the control and HMI technology, which helps us implement the stepwise migration perfectly from a hardware perspective," explains Schätzle. He continues, "Another argument in favor of a single source solution is the lack of problems with interfaces and communication."

APROL provides flexibility through openness

For CHT, the selected integrator would need to be willing and able to accommodate specific requirements and react flexibly to additional changes throughout the course of the project. The contract went to Erler GmbH.

The migration process went smoothly, as managing director Alois Erler confirms: "APROL is very open compared to other process control systems, which allows us to react very flexibly to customer requirements even when a project is already underway. We were also very pleased with how easy it was to link up to the existing legacy system. That went astoundingly well."

23,000 X20 I/Os installed

The first migration was completed in late 2011 on an immensely complex pilot station with around 360 digital and 20 analog I/O channels, and since then a new production station has been migrated nearly every week. To date, 72 systems at the Dusslingen plant and 11 production lines in Oyten had been migrated to APROL and the old process control system retired. 54 HMI panels from B&R's Power Panel series and 91 X20 controllers were installed. The two plants combined have around 23,000 digital and analog X20 I/Os. Various operator terminals connected via VNC were installed for shift supervisors and to provide links to office applications.

Each system includes two runtime servers, one engineering server and a VNC server secured by a disaster recovery system. The redundant Linux-based production network communicates with Windows devices on the corporate network via a clearly defined interface.

Double redundancy guarantees availability

"We have even incorporated double redundancy," adds Schätzle. Every component in a station can be reached via two bus systems: an operator bus and a process bus. Each bus can take over for the other if it becomes necessary. In addition, each station is equipped with two ports that can back each other up. This ensures the high availability that the stations demand.

Before the migration was even complete, it was clear that CHT had found more than simply a replacement for the old system. "The APROL system is significantly more flexible, and we can now have a new valve up and running in a matter of hours rather than days. Any changes to the software can also be reversed with a single click if an error is detected."

Analyzing process sequences is also a much simpler task these days. "With TrendViewer and AuditTrail, we found that we were able to analyze processes that we didn't have access to before," explains Schätzle. "APROL lets us analyze interactions between processes in real time in order to implement process optimizations on the spot. Failed batches can be tracked and analyzed later on based on the logged process data." One way that CHT uses this additional information is to analyze and reduce energy consumption.

Future projects with APROL

Since July of 2015, CHT now has ISO 50001 certification for all of is locations in Germany. The next step for the energy management system is to implement energy data acquisition with APROL. This project began in September 2015. Since the alarm systems in Dusslingen and Oyten also needed to be replaced, CHT decided to use APROL for those as well.

"We're now benefiting from the synergy of B&R's Energy Monitoring and Condition Monitoring solutions by expanding the networks at the two locations and connecting all signals with APROL," says Schätzle. This project, which will also be implemented first in Dusslingen and subsequently in Oyten, will ultimately add 4,000 I/Os to the process control system. Upon completion, CHT hopes that centralized evaluation of this newly won data will help tap potential energy savings and improve plant safety and system availability.

Fast and flexible reactions

CHT is already busy thinking up other ways they can utilize the flood of data they have tapped into. In 2017 they will begin development of a custom manufacturing execution system (MES) to utilize the data with an interface to the ERP system.

"We've been very happy with the progress of the migration so far. The stepwise approach, the parallel operation of the APROL and legacy systems – all that hardly affected our production, and we had no data loss whatsoever," says Schätzle, pleased. "This system allows us to react flexibly and quickly to the latest developments and implement changes cost-effectively. These positive results have motivated us to further expand the existing system and implement comprehensive planning and evaluation tasks with APROL.

"APROL provides optimal support for stepwise migration. We have migrated our production plant step by step to the B&R process control system while the legacy systems continue to run in parallel." Günther Schätzle, Head of Production Engineering, CHT