By coupling their power, heating and cooling systems, the wholesale fruit market in Mittelbaden, Germany, managed to reduce the energy costs associated with operating its cold storage facilities by 50%. At the heart of the network is a central controller based on a B&R Power Panel, which ensures that the individual systems interact with optimal efficiency.

Over the course of a year, the local-grown apples on your supermarket shelves actually leave a larger ecological footprint than their imported cousins. This has been confirmed by studies comparing the carbon dioxide emissions associated growing, transporting and storing fresh produce. Surprisingly, the environmental cost of energy-intensive cold storage significantly outweighs that of transporting freshly harvested fruits from large plantations halfway around the globe.

Yet the scales may soon tip in favor of your friendly local orchard. By creating intelligent links between their various supply systems and incorporating renewable energy, producers of pharmaceuticals, foods and beverages as well as plastics processors, hotels and, of course, cold storage facilities can minimize the impact of their energy-intensive enterprises on both the environment and their bottom line.

High energy consumption

Case in point: the wholesale fruit market in Mittelbaden. At its headquarters in Oberkirch, between the Rhine and the Black Forest in one of Germany's largest fruit-growing regions, the 3,100-member producer group operates more than 50 cold storage facilities home to a total of 550 cold rooms, 45 freezer rooms and 12,100 controlled atmosphere rooms for 11,000 metric tons of pome fruits.

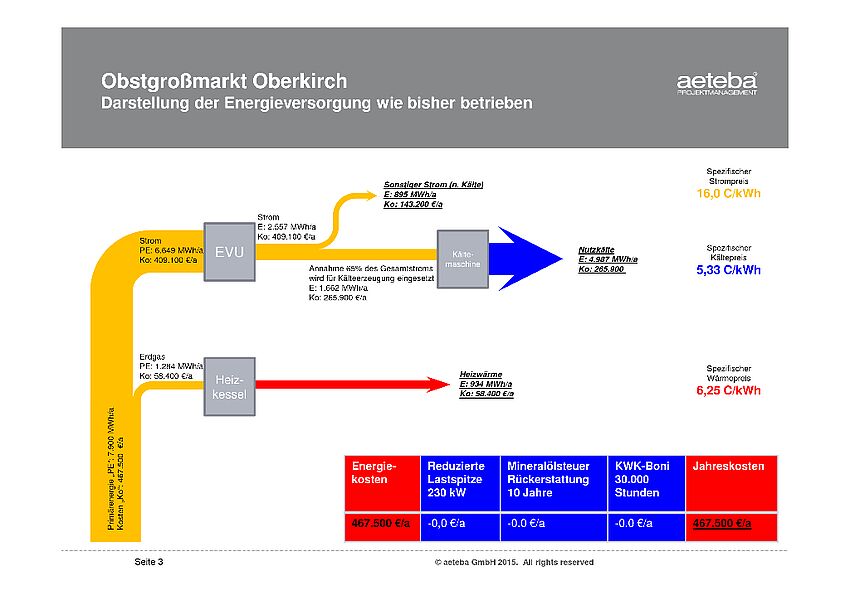

Until late 2014, the 4,987 megawatt hours of refrigeration these facilities require each year were generated using conventional chillers. This alone accounted for an estimated 65% of the market's total power consumption of 2,557 megawatt hours, with the rest going to operation of the cleaning, sorting and packaging lines. To provide the necessary electricity – at a total cost of €409,100 per year – the utility company consumed a calculated 6,649 megawatt hours of primary energy. This doesn't even account for the €58,000 of gas – another 1,284 megawatt hours of primary energy – needed to heat the buildings.

Custom-tailored intelligent energy supply

"In the past, the heating and cooling systems operated completely independently of one another," explains Elmar Sporer, the R&D manager at aeteba who was responsible for planning and implementing the new energy generation and distribution solution for the wholesale warehouse. "While this kept the design relatively simple, it didn't make efficient use of the available energy."

A solution that is both ecologically and economically optimized must account for every process involved in generation and distribution of heating, cooling and power. Most importantly, it must be custom-designed in a way that allows for intelligent interaction between these systems.

"Since the circumstances vary from location to location," explains Sporer, "the supervisory controller responsible for networking the energy systems needs to be easily adaptable. Off-the-shelf controllers we found only covered a portion of our needs or were simply to rigid, so we chose to develop our own solution based on standard B&R components."

Scalable and adaptable control

For aeteba, the decisive arguments in favor of B&R technology were the scalability and modularity that make it particularly cost-effective. At the heart of the new control solution is a Power Panel that serves double duty as both HMI and control platform. For the wholesale market in Mittelbaden, aeteba selected a fanless Power Panel 520 with an Intel Atom processor and a 15" touch screen display. If necessary, the HMI and control applications created in Automation Studio can easily be ported to a Power Panel variant with a more powerful processor or larger display or to an industrial PC with a remote operator panel. In cases where production data acquisition is desired, the APROL process control system can also be integrated. To communicate with the various system components, aeteba uses modules from B&R's X20 and X67 systems. The latter offers IP67-rated I/O modules that allow designers to control remote subsystems or integrate them directly, via X2X for example.

80% of electricity produced in-house

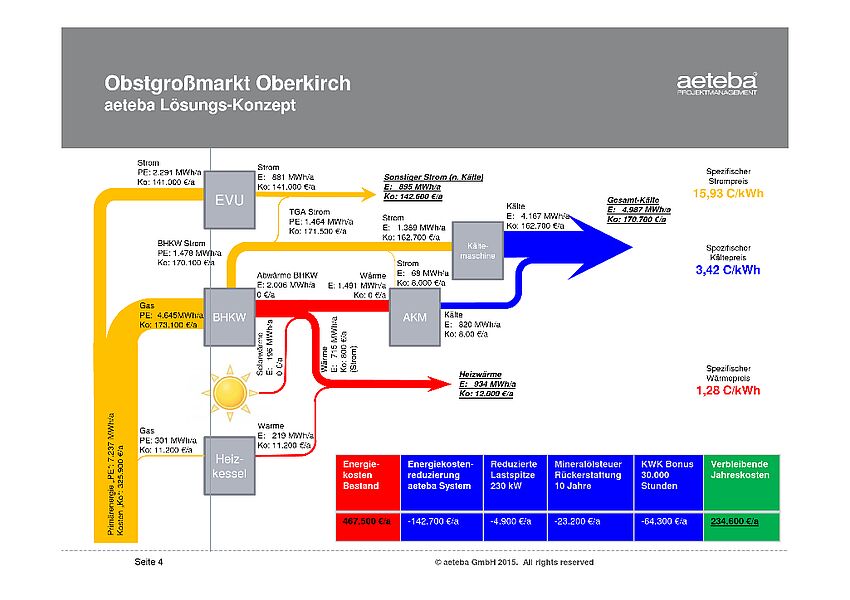

The wholesale fruit market in Oberkirch has been using this solution to control the new energy supply system implemented by aeteba, which is built around a combined heat and power unit with electrical and thermal capacities of 200 and 256 kilowatts, respectively. For economic reasons, the system was designed to cover 80% of the facility's total electricity requirements. Electricity generated in-house is used almost exclusively to operate the chiller (1,389 megawatt hours or €162,700 per year), leaving only 881 megawatt hours to be purchased from the utility provider. Additional cooling energy (820 megawatt hours) is provided by an absorption refrigerator that utilizes waste heat from the combined heat and power unit. Supplemental power for the heating and cooling systems is provided by 409 square meters of solar panels (219 megawatt hours) and a small gas boiler (219 megawatt hours).

"The advantages of B&R's solution are its scalability, modularity and ease of use. On top of giving us remote maintenance possibilities that grant us access down to the field level, B&R's technology allowed us to create a control solution that quickly and easily adapts to each location's customized energy supply system to guarantee high availability." Elmar Sporer, R&D Manager, aeteba GmbH

Energy costs cut in half

The combination of custom-tailored energy supply systems and the control solution from B&R made it possible establish optimal interaction between the systems and cut the wholesale fruit warehouse's energy costs in half – from €467,000 to only €234,000 – in spite of incorporating a previously unrefrigerated auction hall into the climate control system.

This explains Sporer's optimistic outlook on the future: "Combined cooling, heat and power has proven to reduce energy costs and improve the carbon footprint of nearly all energy-intensive enterprises with continuous consumption over 100 kilowatts of electricity who also need thermal energy for refrigeration and/or heating. The investment costs pay for themselves in a few years, and it benefits both the climate and society."