What today is paraded under the banner of Industry 4.0 has been common practice at B&R's own production facilities for nearly a decade. The smart factory in the Upper Austrian town of Eggelsberg has been fully networked since 2006 and is being upgraded all the time.

For its latest project, B&R optimized production of its industrial PCs. Using an online configuration tool, B&R customers assemble their PCs to their exact specifications. After verifying the feasibility of the configuration, the ERP system automatically generates a bill of materials with a unique serial number.

250 billion possibilities

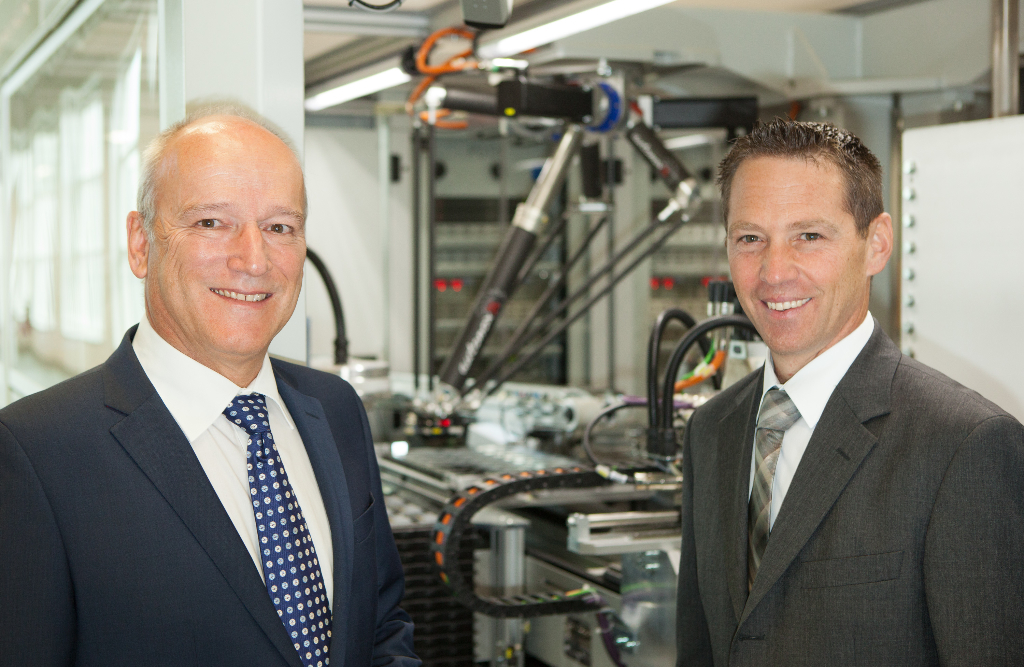

"Mathematically speaking, the customer has more than 250 billion different hardware configurations to choose from," says Gerald Haas, head of global industrial management at B&R. That's without considering all of the software options. Most order quantities are in the two to three-digit range. "The way we're set up, order quantity is irrelevant," says Haas. "We can produce a one-off item with the same efficiency as a batch of 1000."

The ERP system plans an optimized order processing schedule and ensures that the logistics run smoothly. Parts that come from the warehouse are delivered just in time. This is where one of the advantages of B&R's smart factory comes into play. The plant in Eggelsberg is completely networked – both horizontally and vertically.

A single, homogeneous network

"What's special about our solution is that we don't have a collection of subnetworks that are interconnected with varying degrees of efficiency," says Haas. "What we have is a single, homogeneous network that incorporates every machine and every building automation component as well as the ERP system." That's what gives the ERP system the ability to control the automated storage and retrieval vehicles in the high bay warehouse. The ERP system sorts the items in the high bay warehouse according to current and forecasted production volumes and triggers reorders when inventory is running low.

By the time a PC order arrives at a worker's assembly station, all the necessary components are within reach. The worker is guided through the assembly of each PC by on-screen instructions and light signals. Workstations are setup ergonomically and the tables are easily adjusted to workers of different heights.

Each and every PC is tested repeatedly during and after assembly. They are checked for correct assembly and the CPU and RAM are subjected to functional and stress testing. Only when all tests have been completed successfully does the ERP system release the PC for shipping. "After all, every product that our customers receive should work flawlessly," explains B&R's general manager, Peter Gucher.

Seamless traceability

"Functional testing is nothing we've invented," grants Gucher, "but what is fairly unique is the complete traceability we have for every single product." Every step in production, every test and every significant component can be retraced at any time. This traceability extends throughout the entire lifecycle of the product. Even years down the road, based on nothing more than the PC's serial number, you will be able to look up the results of every functional test ever performed on it and clearly identify every component it contains.

"This gives our customers an added layer of certainty," explains Gucher. On its website, B&R provides a service portal where its customers can look up technical data and order-related information by simply entering their product's serial number. This includes version information, delivery date, warranty status and much more. "We're able to save our customers a lot of time and effort this way," adds Gucher.

Real-time dynamics

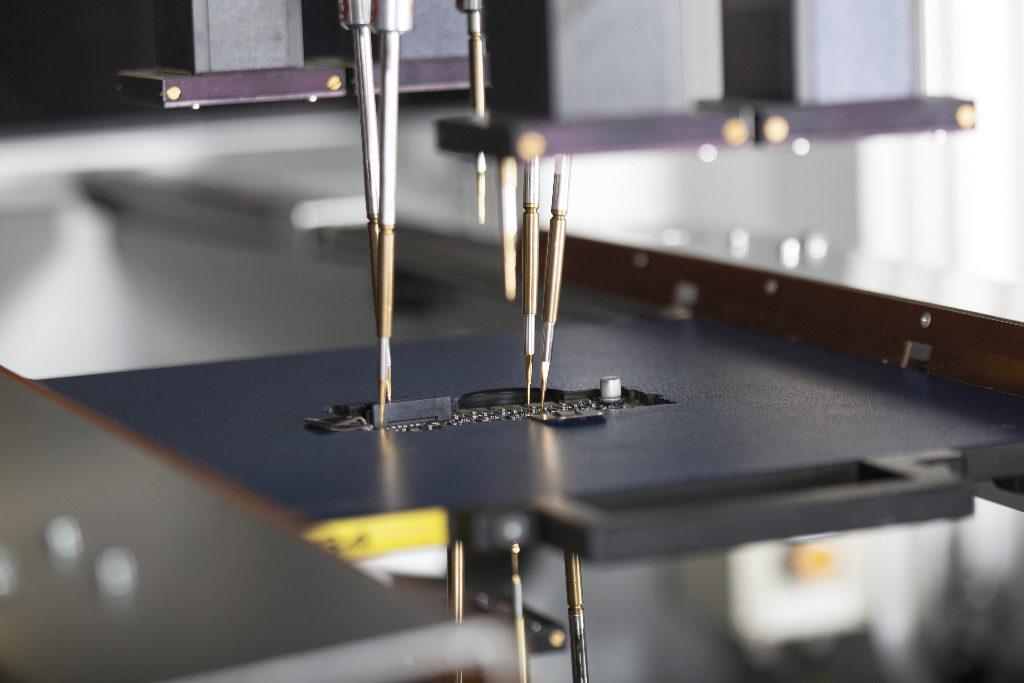

Communication throughout the networked factory works in every direction. "Our X20 modules are a good example of this," says Haas. Currently, there are 200 module types being produced on various lines. When a module reaches the fully automated station for assembly, testing and labeling, a real-time SAP query determines which tests are required. A fraction of a second later, the machine is busy putting the answer it received into action. This is only possible because every product can be uniquely identified by its serial number.

If an R&D engineer makes a note in SAP that a module has received a certain certification, and a module of that type happens to arrive at the labeling station only seconds later, the correct certificate mark will be laser printed on the housing. "That's smart factory technology at its finest," says Haas. Of course, fully networked intelligent production generates its fair share of data. On large systems, the collected data can quickly reach gigabyte or even terabyte levels. "Automated data processing and analysis is essential to reaching an informed decision," says Gucher. That's why B&R collects and evaluates all of its production data using its own APROL process control system.

OEE parameters at any time

In APROL, parameters such as overall equipment effectiveness (OEE) can be viewed at any time and even compared between production lines, shifts or workdays. "With APROL we always have an eye on our energy consumption as well," adds Haas, "so we can make immediate corrections when something is wrong."

B&R sets the bar high when it comes to maintenance, too. Using condition monitoring tools from its own portfolio, B&R is able to determine the ideal timing for maintenance work. This eliminates the waste of replacing parts too early, as well as the risk of waiting too long and damaging a machine. If a key parameter moves out of its defined tolerance, an employee receives automatic email notification and can intervene before the aging component fails and causes an unplanned stoppage.

Industry 4.0 as usual

"For B&R, networked smart factory production has been a reality since 2006," says Haas. "What for us is business as usual, has since been given a name: Industry 4.0."