Typically located at the end of a packaging line, checkweighing systems are used to weigh packaged items and automatically reject any that fall outside the defined tolerance. Checkweighers are a key element in establishing trust between producers and consumers. They also provide manufacturers valuable information to help fine-tune production efficiency and make the most of their raw materials. Thanks to a lightweight, smooth-running automation solution from B&R and perfect POWERLINK synchronization, the new in-motion checkweigher from Precia Molen is able to process products weighing fractions of a gram at a rate of over 120 packages per minute.

In-line weighing for food production

Precia Molen has been France's leading manufacturer of weighing instruments for more than 50 years and is widely recognized as an expert in the field. Originally known as Precia, the company acquired Molen in 1993 and has enjoyed continuous international growth ever since. Besides ensuring compliance with weight measurement regulations, their newest CKW710 in-motion checkweighers – automated by B&R – also meet the demands of today's food industry for high-speed line-integrated weighing.

The CKW710 is comprised of three conveyor belts. First comes an infeed belt, which accelerates or decelerates the incoming packaged item to the speed required for weighing. This is followed by a weighing belt mounted on a weight transducer and a rejection belt to remove out-of-tolerance packs from the line. An additional feed for electromagnetic inspection is also available to detect any metallic particles and ensure product integrity.

Motion control for high-speed weighing

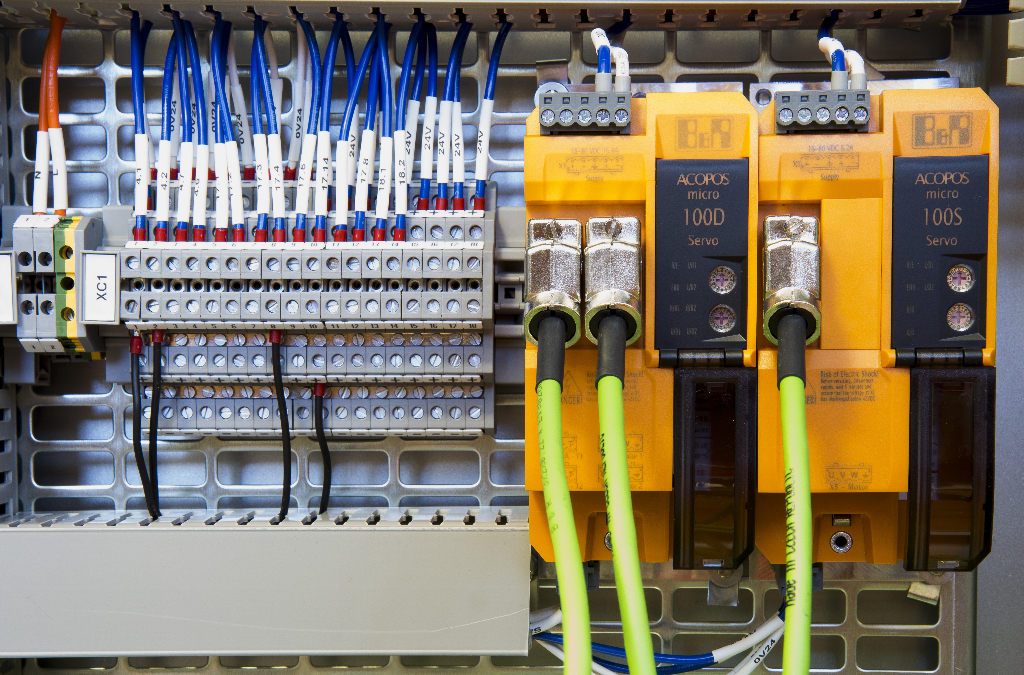

All four belts are driven by brushless motors and compact ACOPOSmicro servo drives from B&R. Because weight measurements are very sensitive to vibration, the Precia Molen R&D team needed the drive system to be lightweight and to generate minimal mechanical noise when moving the belts. Thorough testing validated that the ACOPOSmicro servo drives were well suited for such constraints.

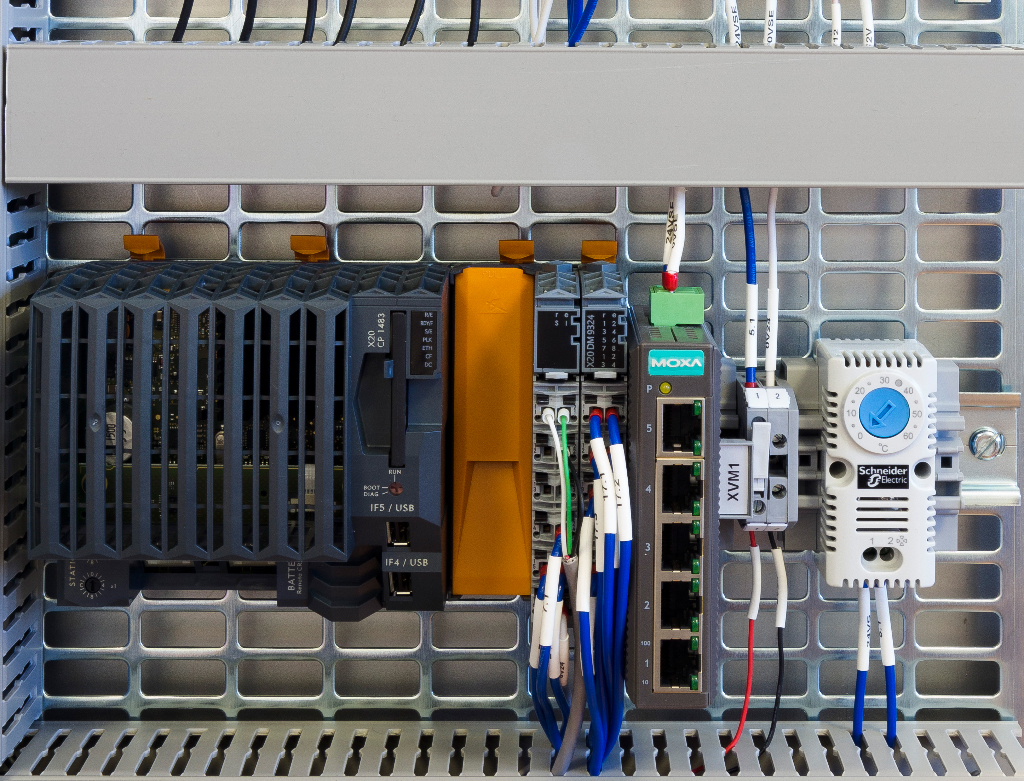

The servo drives are controlled by a compact X20 controller via a POWERLINK network. The Ethernet-based POWERLINK network ensures optimal synchronization between the machine's detection sensors and the ACOPOSmicro servo drives. Based on this automation solution, Precia Molen's dynamic in-motion checkweigher handles 100% of production flow – processing items weighing fractions of a gram at over 120 packages per minute.

Highly connective controller

The sophisticated checkweighing software Precia Molen developed for the CKW710 allows it to evaluate weight, control rejection systems and manage statistics through a modern graphical interface. Data exchange with customers' IT systems is based on Ethernet. The full connectivity offered by the X20 controller made it easy to couple this evaluation system with the B&R axis control solution.

Communication was easy to program thanks to the many libraries offered by B&R's Automation Studio software tool. Using the X20 CPU and I/O modules, the CKW710 can send a signal to upstream machines like fillers or sealers if to trigger adjustments to control parameters.

"The B&R team has always been by our side whenever we needed technical support, even on-site. This helped move the project along quickly and reduced our time-to-market significantly." Yvan Ruillère, Project Manager, Precia Molen

Efficient training to reduce time-to-market

Engineers from Precia Molen and B&R worked together very closely to make the checkweigher project a success. Thanks to the training services provided by B&R France, the Precia Molen project team was brought up to speed on B&R motion control technology very quickly. "The B&R team has always been by our side whenever we needed technical support, even on-site. This helped move the project along quickly and reduced our time-to-market significantly," reports Yvan Ruillère who led the CKW710 project