In the field of factory automation, operator panels are increasingly being mounted on swing arms. The advantages are clear: They are much more flexible than their cabinet-mounted counterparts with regard to placement and positioning and allow operators to keep an eye on the production process at all times. B&R's latest generation of swing-arm-mounted HMI – the Automation Panel 5000 – sets new standards in versatility and modularity.

While their predecessors were generally connected to a remote industrial PC, today's decentralized control architectures increasingly demand panels with onboard intelligence – in the form of integrated PC components. Offering a solution for either scenario, the Automation Panel 5000 can be set up as a remote terminal or an integrated Panel PC. This involves equipping it with either a PC unit or a receiver for B&R's high-performance digital display technology, Smart Display Link (SDL/SDL3). Either way, the operator panel itself is identical.

A wide selection of Automation Panels are available for swing-arm mounting. One way to go is the traditional 4:3 format with an analog resistive touch screen – which ensures compatibility with many existing applications. These are available in sizes up to 19" and in the widely used XGA and SXGA resolutions.

Swipe, zoom, scroll

Alternatively, you have multi-touch systems, which are quickly gaining popularity in industrial environments. They offer intuitive swiping, zooming and scrolling gestures as well as two-hand gestures to prevent the inadvertent triggering of critical operations.

The edge-to-edge glass surface is as nice to use as it is easy to clean. Multi-touch widescreen panels are available in sizes ranging from 15.6" to 24" with either HD Ready or Full HD resolution.

Powerful system on a chip

Today's complex control and HMI applications are computationally intensive. With its latest generation of Atom processors, Intel has created a compact yet powerful system-on-chip (SoC) platform that lends itself ideally to use in space-saving Panel PCs. These processors are scalable – single core, dual core or quad core – and achieve performance values comparable to Celeron processors based on the Core i-series.

Graphics performance has also taken a big step forward. For the first time in this segment, the Atom processors support Direct X11, used in many modern SCADA systems. At the same time, the systems are exceptionally efficient. The E3815 single core processor has a thermal design power (TDP) of only 5 watts – even the quad core tops out at 10 watts – allowing the Panel PCs to be entirely fanless. The PC units take up no more space than the compact SDL/DVI receiver does.

From control to HMI

Panel PCs are suited to a wide range of applications. The multi-core architecture of the latest generation of Intel Atom processors makes it possible to combine multiple functions in a single system. One core can handle control tasks, while the others simultaneously run a Windows-based SCADA system.

B&R's swing-arm-mounted Panel PCs offer flexible interfaces to ensure that they are equipped to handle whatever is required of them. Two Gigabit Ethernet interfaces come as standard, while a modular interface module can be installed to add POWERLINK, CAN and more. Data is stored on a CFast card that provides up to 128 gigabytes of space. Two USB ports – one of them USB 3.0 – offer a quick way to connect additional peripheral devices.

B&R's Panel PCs can run a variety of operating systems, including various Windows versions up to Windows 10, as well as embedded variants with additional advantages such as configurable write filters. It is also possible to use Linux or B&R's real-time Automation Runtime.

Maximum convenience

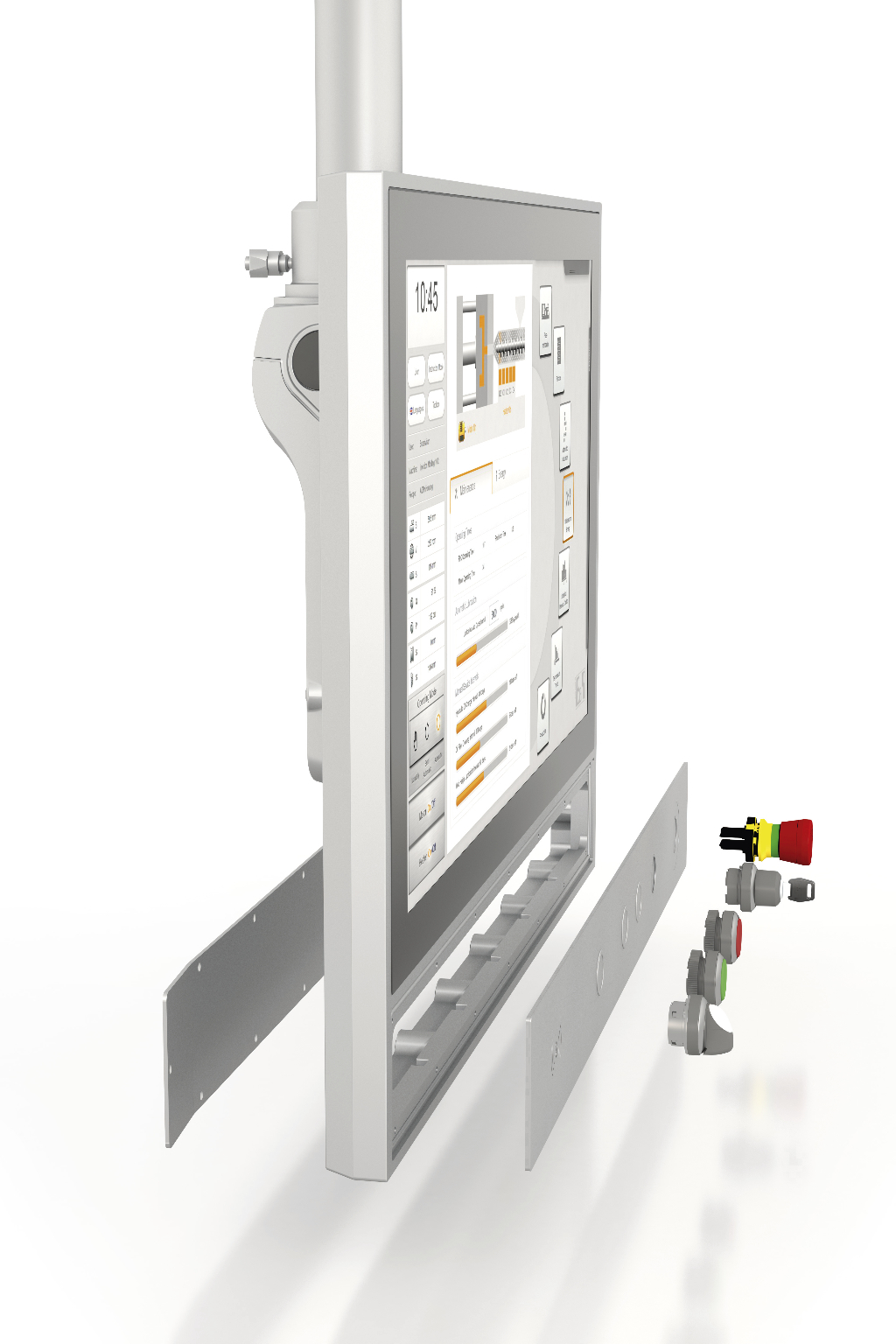

Touch screens open up a new world of possibilities for user interaction. Nevertheless, users continue to prefer mechanical elements for certain operations. That's why B&R offers its Automation Panel 5000 with optional push buttons, selector switches and key switches. An E-stop button can also be installed on the swing-arm device, where it is always within the operator's reach.

Used to manage access rights in many facilities, RFID keys can just as easily control access to operator terminals. Selected variants of the Automation Panel 5000 can be equipped with RFID readers to allow intelligent user-group authorization. The easily abused practice of jotting down passwords on scraps of paper can finally be put to rest.

Easy customization

The arrangement and design of the keys on the operator terminal vary from machine to machine. To adapt optimally to the needs of each machine, B&R has made its keypad modules very easy to customize. Since the basic hardware is always the same, the process is extremely simple. The list of possible adaptations is long, including virtually any arrangement of standard keys, illuminated ring keys and push buttons in various colors.

Custom HMI devices are generally delivered fully assembled. A custom keypad module is also available for installation by the user. The removable cover on the back of the panel makes cabling quick and painless. Inside, two separate cable channels guide the cables into the swing arm. This allows the operating elements to be adapted perfectly to the application, even on one-off custom devices.

Flexible mounting

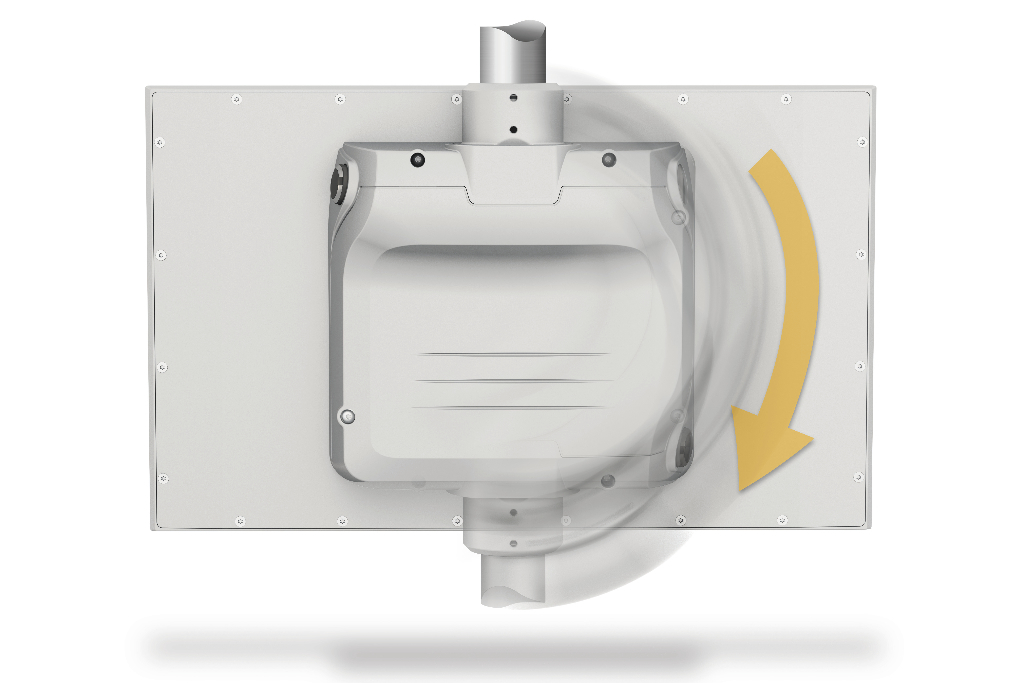

B&R Automation Panels can easily be adapted for pendant or pedestal mounting. The mounting direction is up to the user and can be changed on site. The panels are designed to allow easy access to all operating elements and cables.

This is done by removing the entire back cover, which – like panel itself – offers IP65 protection. Side grips can be installed so that the user can easily move the panel into the optimal position. The optional swivel-tilt flange allows the panel to be adjusted to an ergonomic viewing angle so that workers of various heights can use it comfortably and without fatigue. As an alternative to the swing-arm system, the Automation Panel 5000 can also be installed on a VESA monitor mount.

Author: Raimund Ruf, Business Unit Manager - HMI, B&R