One process control system for many disciplines

The APROL process control system and the B&R X20 system automation components are continually faced with new challenges: APROL is used in all sectors of the process, manufacturing and hybrid industries. This is a versatile and flexible process control system and automation platform for controlling, monitoring and optimizing industrial processes and plants. It is also used in infrastructures for water treatment, manufacturing and energy management. Plants that are automated with the APROL process control system often belong to critical infrastructures (CRITIS).

Full scalability

APROL offers full scalability to meet the requirements of different application areas. This means that the system can be flexibly adapted for systems ranging from a single node with 50 I/Os to a large plant with several hundred thousand I/Os. Whether it is a single facility with limited resources or a large facility with many components, APROL can be scaled accordingly to ensure optimal performance and functionality. It is precisely this scalability that allows companies to efficiently adapt their automation solutions to their specific needs.

The development of process control systems is a complex and time-consuming process that includes all phases from planning and development to implementation and commissioning. In this demanding environment, time pressure, coordination and managing high complexity are often the biggest challenges. This is where APROL plays to its strengths by integrating all automation components in a common engineering tool. This significantly reduces the time needed for the design and engineering phases while ensuring data consistency.

The APROL process control system is the result of three decades of experience in developing integrated automation technology at B&R. Not so long ago, many industries and market segments had not even considered implementing a process control system. Today, users appreciate the ability of an industrial control system to support multiple users simultaneously while enabling management of very large amounts of data. At the same time, data is managed consistently throughout the engineering system and seamless integration of different fieldbus systems is possible.

Connectivity at all levels

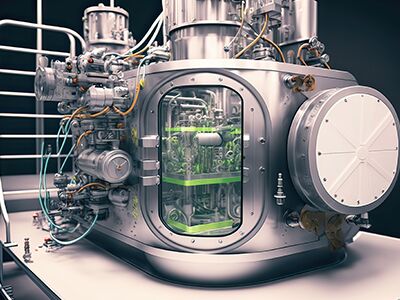

APROL industrial control system (ICS)

The APROL industrial control system (ICS) is a comprehensive, integrated automation system and distributed control system (DCS) in one. APROL ICS is used to control, monitor and optimize industrial processes in various industries. It offers a wide range of functions and tools to handle complex automation tasks. With APROL, customers are able to further develop their automation solutions and improve their production processes.

APROL Edge Controller

The APROL Edge Controller is a dedicated control device integrated into the APROL platform. It is often used in decentralized automation scenarios to bring process control and monitoring closer to the system. The Edge Controller is able to perform local tasks and process data directly on site before forwarding it to the higher-level automation system. The APROL Edge Controller thus offers a way to improve the performance and efficiency of automation solutions by integrating local intelligence and control into the overall system.

Process automation for your industry

Solutions for power generation

Phasing out coal-fired power generation and increasing the use of more environmentally friendly energy sources such as solar energy, biomass, wind power, geothermal energy and hydrogen are crucial steps needed to meet the challenges presented by climate change. In this transition to more sustainable energy sources, highly available and scalable industrial control systems like APROL are becoming increasingly important.

With APROL, companies can ensure that their power generation processes are operated in an efficient, environmentally friendly and sustainable manner. This will help reduce CO2 emissions and promote a greener future, which is urgently needed to curb climate change.

Maritime solutions

Large ships worldwide require a reliable and robust automation solution that can safely withstand the demanding conditions at sea. In view of the wide range of automation tasks on board, numerous APROL DCS-based functions are used.

Infrastructure automation

Critical and industrial infrastructures require maximum availability and security. APROL meets these requirements by using redundancy at all levels, from sensors to HMI. In addition, APROL supports compliance with industrial cybersecurity standards to ensure a robust security infrastructure.

FDA compliant report generation / Batch report

For machine lines, and especially in validated medical device manufacturing processes subject to FDA Part 11 regulations, a reliable solution for data acquisition and orchestration is critical. In addition, electronic records must be recognized as valid in accordance with FDA guidelines. APROL provides the necessary functionality to meet these requirements and ensure that data collection and management correspond to regulatory standards.

Edge Controller for data acquisition

APROL - Hardware Subsequently, the collected data is either stored directly in the database as raw values or subjected to processing/calculations beforehand. The collected data is then sent to the cloud via MQTT on hourly or daily basis.

Contact us to receive more information about APROL

Lorem Ipsum is simply dummy text of the printing and typesetting industry. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

Value Provider Network

Additional materials such as documentation or release notes can be found in our download portal. Use the filter to find the APROL version you want and the corresponding downloads.

In our Automation Academy we offer product-specific training. Use the “Seminar” filter to find the right training.

Fairs and events

Which trade fairs and events do you attend? You can find our schedule in our event calendar. We look forward to meeting you at one of our exhibition stands!